Preparation method of aragonite type calcium carbonate whiskers

A calcium carbonate whisker, aragonite-type technology is applied in the field of preparation of aragonite-type calcium carbonate whiskers, which can solve the problems of complex preparation process, high cost of auxiliary agents and high risk, and achieves simple preparation process and easy scale. The effect of reducing production and equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A kind of preparation method of aragonite type calcium carbonate whisker of the present invention comprises the following steps.

[0024] 1) Take 200 mL of calcium chloride-rich solution, and adjust the pH value of the solution to 7 with ammonia water or hydrochloric acid to obtain a neutral calcium chloride solution.

[0025] Among them, the calcium chloride-rich solution described in step 1) is mainly the calcium chloride-rich waste liquid obtained from the alkali industry, the hydrochloric acid leach solution of calcium ion-rich minerals or the solid waste rich in calcium ions hydrochloric acid leaching solution; the concentration of calcium ions in the calcium chloride solution is 3-20 g / L, and the concentration of calcium ions in the calcium chloride solution is adjusted by adding industrial water or calcium chloride powder.

[0026] 2) Mix the calcium chloride solution obtained in step 1) with ammonia water, place it in a stirred reaction vessel, and feed CO at th...

example 1

[0032] The calcium chloride solution in the present embodiment is the hydrochloric acid leach solution of phosphogypsum, and the main chemical composition of phosphogypsum is, by weight percentage: SO 3 40%, CaO30%, SiO 2 5%, other 25%; the concentration of calcium ions in the solution was adjusted to 4.2 g / L by adding analytically pure calcium chloride, and the pH value of the solution was adjusted to neutrality by adding ammonia water; CO 2 Gas industrial grade, purity 99%, the specific process is as follows:

[0033] 1) Take 300 mL of the above calcium ion solution in a beaker, add 45 mL of ammonia water to the solution, place the beaker in a stirred reaction vessel, and pass CO 2 gas, CO 2 The flow rate was 63 mL / min, the stirring speed was 118 r / min, and the reaction was stirred at 94 °C for 66 min. After the reaction was completed, the solid reaction product was obtained by suction filtration;

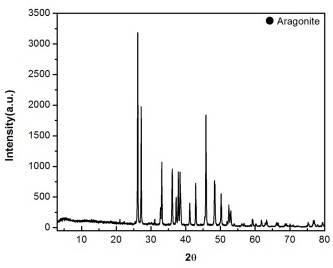

[0034] 2) Wash and dry the above solid reaction product to obtain a calci...

example 2

[0037] The calcium chloride solution in this embodiment is the waste liquid produced by the soda-making industry. The concentration of calcium ions in the solution is adjusted to 10.7 g / L by adding analytically pure calcium chloride, and the pH value of the solution is adjusted to neutrality by adding ammonia water; CO2 Gas Industrial grade, purity 99%, the specific process is as follows:

[0038] 1) Take 200 mL of the above calcium ion solution and place it in a beaker, add 36 mL of ammonia water to the solution, place the beaker in a stirred reaction vessel, and feed CO 2 gas, CO 2 The flow rate was 132 mL / min, the stirring speed was 372 r / min, and the reaction was stirred at 158 °C for 133 min. After the reaction was completed, the solid reaction product was obtained by suction filtration;

[0039] 2) Wash and dry the above solid reaction product to obtain a calcium carbonate whisker sample;

[0040] 3) The arsonite content of the calcium carbonate whisker sample obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com