A self-polymerized microporous polyimide gas separation membrane and its preparation method and application

A technology of gas separation membrane and polyimide, applied in separation methods, semi-permeable membrane separation, dispersed particle separation, etc., can solve the problem of low gas flux, achieve high selectivity, good thermal stability and mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]

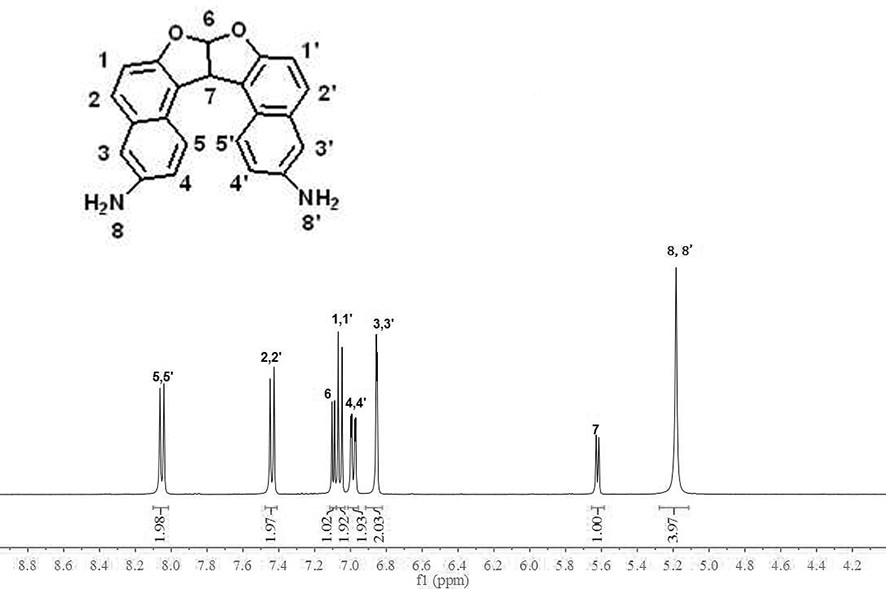

[0042] (1) In a nitrogen atmosphere, 9 ml of a mixed solvent of tetrahydrofuran / trifluoroacetic acid (V:V=1:2) was added to a round-bottomed flask containing 1.5282 g of 2-naphthol. 0.3076 g of glyoxal was added dropwise under stirring, and after the resulting mixture was reacted at room temperature for 3 hours, saturated NaHCO was added thereto. 3 aqueous solution, adjust pH=7, and quench the reaction. After that, it was extracted three times with dichloromethane (30 mL×3), the organic phase was separated and dried over anhydrous sodium sulfate, and the solvent was removed by rotary evaporation to obtain a crude product. Finally, column chromatography [SiO 2 , V (petroleum ether): V (dichloromethane) = 6: 1] separated to obtain white cotton wool needle-like five-membered epoxy hetero-bridged naphthalene ring structure monomer (7a, 14c-dihydronaphtho[2,1-b ]naphtho[1',2':4,5]furo[3,2-d]furan), the yield was 70%;

[0043](2) Suspend and dissolve 2 grams of white ...

Embodiment 2

[0046]

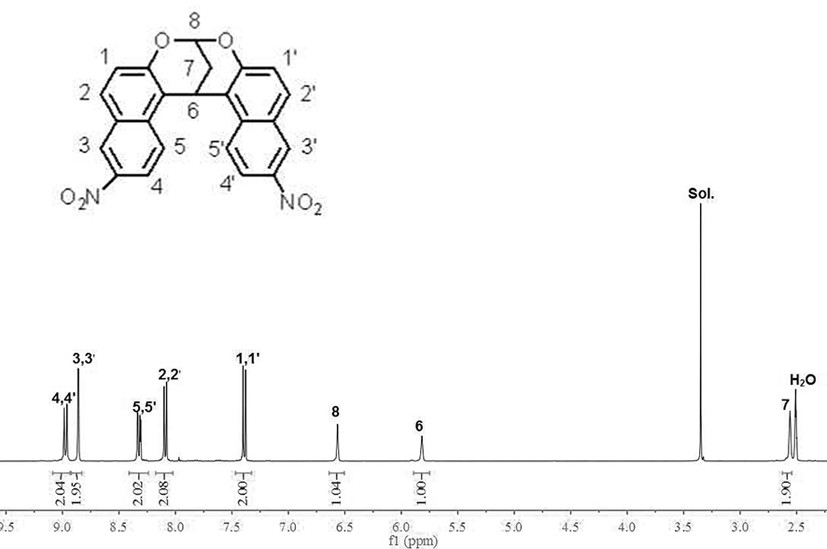

[0047] (1) In a nitrogen atmosphere, 9 ml of a mixed solvent of tetrahydrofuran / trifluoroacetic acid (V:V=1:2) was added to a round-bottomed flask containing 0.995 g of 2-naphthol. 0.576 g of 1,1,3,3-tetramethoxypropane was added dropwise with stirring, and after the resulting mixture was reacted at room temperature for 3 hours, saturated NaHCO was added thereto. 3 aqueous solution, adjust pH=7, and quench the reaction. After that, it was extracted three times with dichloromethane (30 mL×3), the organic phase was separated and dried over anhydrous sodium sulfate, and the solvent was removed by rotary evaporation to obtain a crude product. Finally, column chromatography [SiO 2 , V (petroleum ether): V (methylene chloride) = 6: 1] to separate and obtain the white six-membered epoxy hetero-bridge naphthalene ring structure monomer (16H-8,16-methyl dinaphtho[2,1-d :1',2'-g][1,3]dioxocane), the productive rate is 87%;

[0048] (2) Suspend and dissolve 2 grams of whit...

Embodiment 3

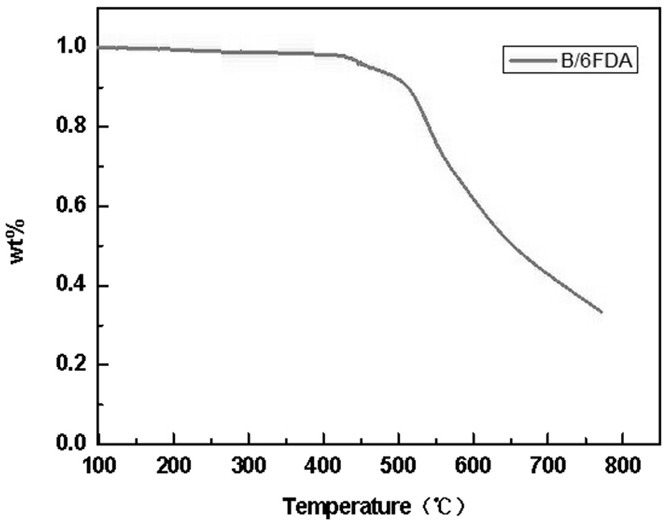

[0052] (1) Under a nitrogen atmosphere, add 12 milliliters of m-cresol in a three-necked round-bottomed bottle with 0.85 gram of A monomer, add 1.11 grams of 6FDA after completely dissolving, add 0.7 milliliters of isoquinoline after completely dissolving, and heat up to React at 80°C for 4 hours, then raise the temperature to 180°C for 12 hours. After the viscous reaction liquid was cooled to room temperature, the fibrous polymer was obtained by precipitation in methanol solution, and the obtained polymer was vacuum-dried at 100° C. for 12 hours after washing for 4 times. Obtain A-6FDA polymer with a yield of 94%; A-6FDA polymer structural formula is as follows:

[0053]

[0054] (2) 0.5 gram of A-6FDA polymer is dissolved in 6.25 milliliters of N-methylpyrrolidone (NMP), obtains 8% casting solution, after filtering, casting solution is poured on a clean horizontal glass plate, 80 °C for 12 hours to obtain a polymer film with a thickness of about 45 microns. At 35°C, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com