Clostridium butyricum and application of clostridium butyricum in immobilized fermentation production of 1, 3-propylene glycol

An immobilized fermentation, Clostridium butyricum technology, applied in fermentation, microorganism-based methods, bacteria, etc., can solve the problems of obvious inhibition, low substrate glycerol tolerance, low production intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

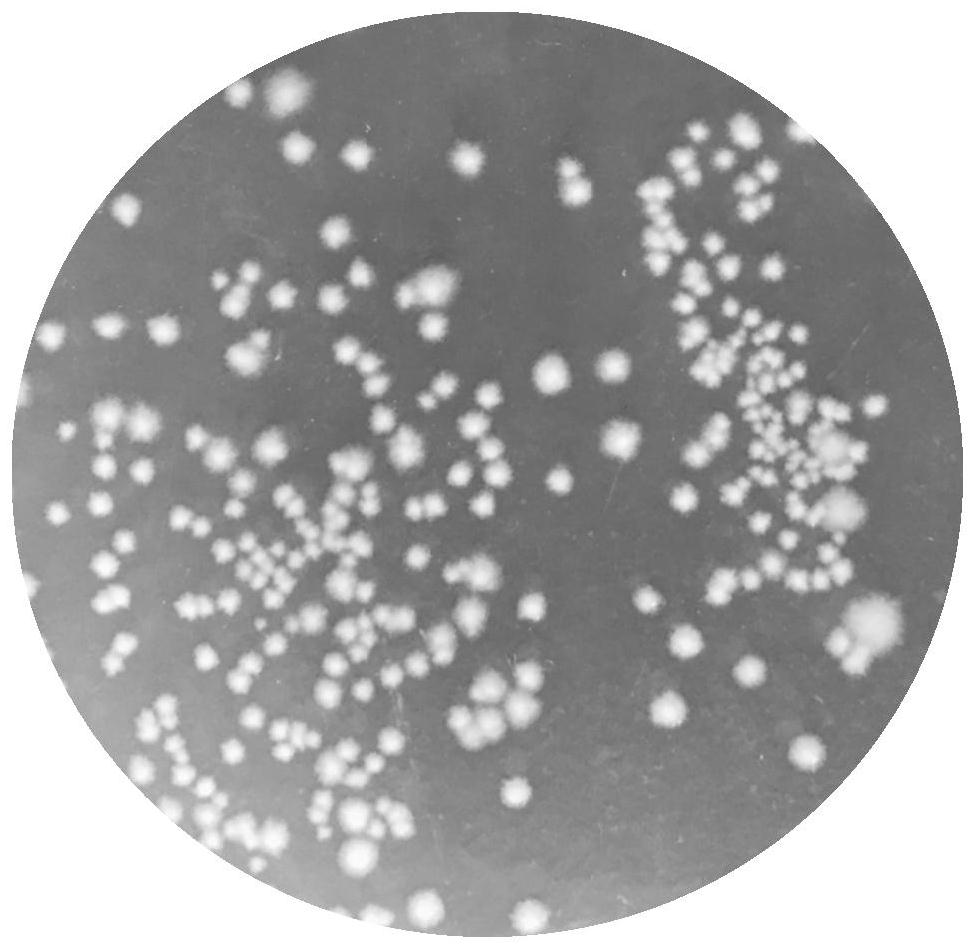

[0035] Embodiment 1, Clostridium butyricum isolation and screening

[0036] Screening method: directly inject 5ml of the collected water sample into 45ml enrichment medium (enrichment medium composition: 41ml of liquid A, the composition is glucose 10g / L; 1ml of liquid B, the composition is tripotassium citrate 100g / L, Citric acid monohydrate 62.5g / L, Na 2 SO 4 50g / L, KH 2 PO 4 50g / L, NaHCO 3 125g / L; C solution 1ml, the composition is urea 250g / L, NH 4 Cl75g / L, yeast extract 50g / L; D liquid 1ml, the composition is cysteine hydrochloride 50g / L, MgCl 2 ·6H 2 O50g / L, CaCl 2 2H 2 O10g / L, FeCl 2 4H 2 O5g / L; E liquid 1ml, the composition is pyridoxamine hydrochloride 1g / L, p-aminobenzoic acid 0.2g / L, Biotin0.1g / L, vitamin B12 0.2g / L, vitamin B1 0.2g / L), 37 ℃ After culturing for 2-4 days, dilute the culture medium to 10 -3 , spread on the screening plate (600ml in total, wherein A solution 450ml, composition is 3g glucose, 9g agar and 0.079g CaCl 2 2H 2 O. B liquid 6...

Embodiment 2

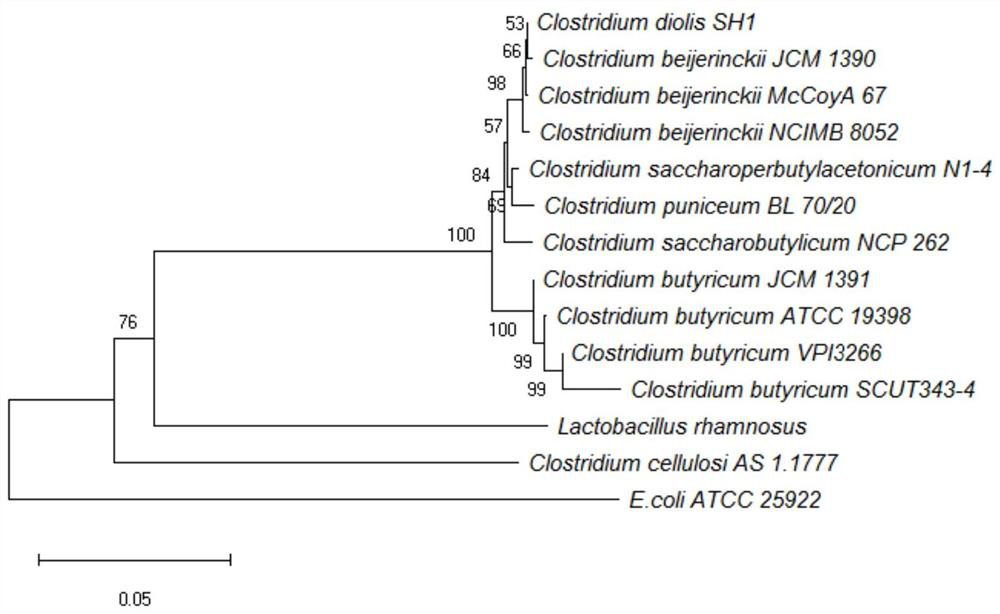

[0037] Embodiment 2, strain identification

[0038] The above strains were subjected to cell morphology identification, 16SrRNA identification, colony morphology identification and fermentation product identification using glycerol as substrate

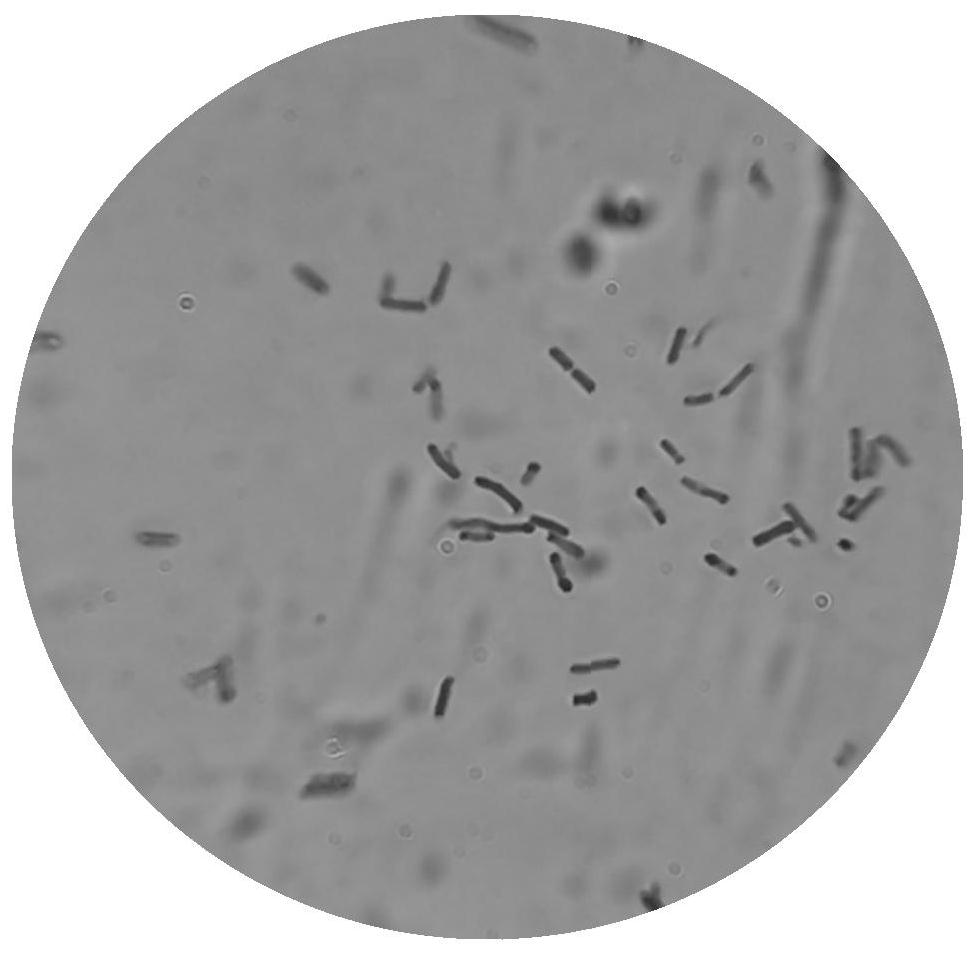

[0039] 1. Morphological identification of bacterial strains

[0040] A single colony isolated in Example 1 was picked and inoculated into a centrifuge tube containing enriched medium, and after anaerobic culture at 37°C for 24 hours, a small amount of bacterial liquid was taken for Gram staining microscope observation. Gram stain test:

[0041] (1) Staining: Take an appropriate amount of bacteria and drop them on the glass slide, fix them by flame 4-6 times, add ammonium oxalate crystal violet solution dropwise, and stain the fixed smears for 1 min.

[0042] (2) Water washing: Slowly rinse the staining solution on the smear with water, and dry it with absorbent paper. Cell morphology can be observed after simple staining.

[0043]...

Embodiment 3

[0057] Embodiment 3, Clostridium butyricum tolerance test to substrate glycerol

[0058] Seed solution preparation: Prepare the fermentation solution as described in Example 2, and after standing for 10 hours, inoculate it into a 100ml shake flask when the OD is 1.5.

[0059] Fermentation medium ( / L): add about 40g, 80g, 120g, 160g, 200g, 240g of pure glycerin; yeast powder 5g; K 2 PO 4 ·3H 2 O1g; KH 2 PO 4 0.5g; (NH 4 ) 2 SO 4 2g; MgSO 4 ·7H 2 O 0.2g; CaCl 2 0.02g; Clostridium butyricum trace element solution 1ml / L; Clostridium butyricum Fe solution 1ml / L.

[0060] Shake flask culture: at 37 ° C, the above seed liquid was inserted into the shake flask by 10% of the fermentation volume, the fermentation volume was 50 ml, and the culture was static, and a sample was taken every about 1 h to test the substrate tolerance ( Figure 5 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com