Synthesis method of D-calcium pantothenate

A synthesis method and technology of calcium pantothenate, applied in organic chemistry methods, chemical instruments and methods, preparation of carboxylic acid amides, etc., can solve problems such as unsuitability for industrial production, long fermentation cycle, and environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

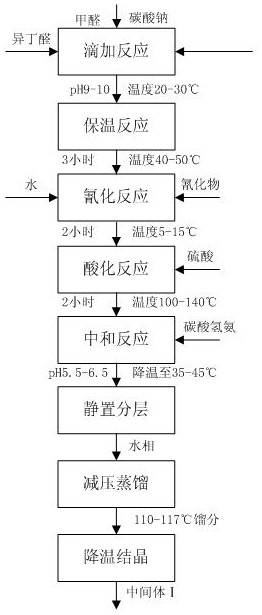

[0051] Synthesis of compound Ⅰ (DL-pantothenic acid lactone)

[0052] At room temperature (20-25°C), adjust the pH value of 324kg (37wt%) formaldehyde solution to 9-10 with sodium carbonate (the amount of sodium carbonate is about 36kg), then add 95wt% isobutyraldehyde dropwise into the formaldehyde solution, The temperature is controlled at 20-30°C, and after the dropwise addition is completed, the temperature is raised to 40-50°C for 3 hours;

[0053] Add 600kg of water to the cyanide kettle, and slowly add 200kg of sodium cyanide to make a 30wt% aqueous solution under stirring, then slowly drop the materials in the above condensation kettle into the cyanide kettle under stirring, and control the dropping temperature 10-15°C, dropwise addition time 2-3 hours;

[0054] Add 70wt% sulfuric acid solution to the above cyanidation product, adjust the pH value to be equal to 1-2, heat and control 120 ° C for 2 hours, cool to about 40 ° C, add ammonium bicarbonate to adjust the pH ...

Embodiment 2

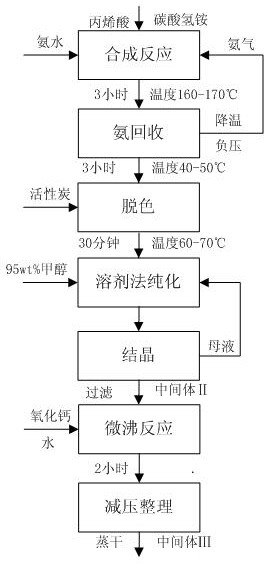

[0056] Synthesis of compound Ⅱ (calcium β-alanine)

[0057] At room temperature (20-25°C), add 400L of water and 150kg of ammonium bicarbonate to the reactor, and then slowly drop 80kg of raw acrylic acid into the reactor for 1.5-2 hours. , After the dropwise addition, react for 30 minutes. If there are more bubbles in the reaction, the time should be extended.

[0058] Pump the materials in the batching kettle into the high-pressure reactor, control the temperature of the reactor at 130-140°C, put in 1200L of 25wt% ammonia water, continue to heat the heat transfer oil to 160-170°C, keep the temperature for 3 hours, and then cool down the system to 40-50°C, after the system pressure drops to 0.1MPa, transfer the material to the ammonia recovery kettle, open the ammonia recovery device of the system, control the system temperature to 40-50°C, vacuum degree ≤ -0.085MPa, first Absorb with high-concentration ammonia water for 1 hour, then stir and absorb with low-concentration am...

Embodiment 3

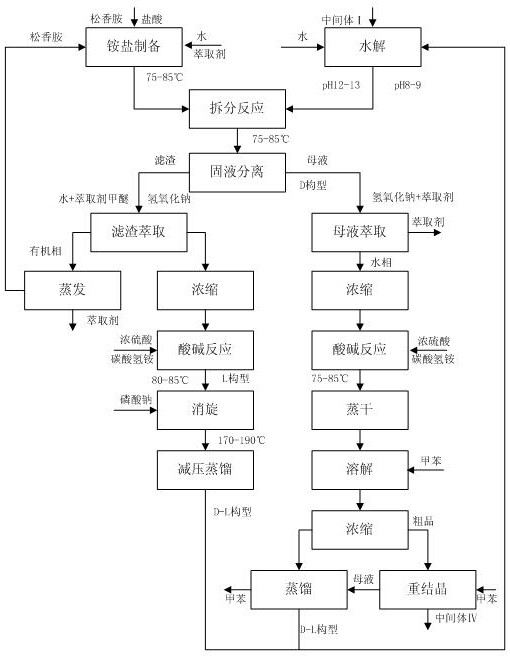

[0062] Synthesis of compound Ⅲ (D-pantolactone)

[0063] Amine salt preparation kettle: Dissolve 215kg of dehydroabietic amine in 400L of methyl tert-butyl ether at room temperature (20-25°C), heat and distill to recover methyl tert-butyl ether until no liquid flows out at 95°C and stop distillation. Then add 600L of water, then use about 27kg of 37wt% hydrochloric acid to adjust the pH value to 3-4, then add 300L of water and transfer to the split kettle for later use.

[0064] Pantothenate hydrolysis kettle: add 500L of water to the kettle, then add 200kg of pantothenic acid lactone, and then use about 65kg of sodium hydroxide to adjust the pH value of the system to 13-14 under stirring, then stir and heat up to 80°C, and keep warm for 30-60 Minutes, then add dilute hydrochloric acid to adjust the pH value of the system to 8-9.

[0065] Put the material in the hydrolysis tank into the split tank and mix it with the prepared amine salt, control the mixing temperature at abou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com