Preparation method of THEIC modified melamine formaldehyde resin

The technology of melamine and formaldehyde resin is applied in the fields of chemical industry and polymer material auxiliaries, which can solve the problems of difficulty in coloring, waste water containing sodium chloride, large solvent loss, etc. Simple, no three wastes discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] Preparation of flame retardant PP samples: Extrude PP and IFR in a twin-screw extruder (rotating speed 20-30rpm) at 190-200°C at a mass ratio of 70:30, mix and granulate. The dried granules are molded with a tablet press at 200-210°C under a pressure of 5MPa, then cold-pressed under a pressure of 5MPa, and then cut into strips of required specifications for performance testing.

[0025] Flame retardant performance test: vertical combustion test adopts CZF-3 horizontal and vertical combustion tester (Nanjing Jiangning District Analytical Instrument Factory) referring to GB / T2408-1996 test, and the sample size is 100mm×13mm×1.6mm.

[0026] The polypropylene used in this application (abbreviated as PP) is the PPSP179 type copolymerized polypropylene produced by China Petroleum & Chemical Co., Ltd. Qilu Branch and the PPH8020 homopolymerized polypropylene produced by Lanzhou Petrochemical Company of China Petroleum and Natural Gas Co., Ltd., both by mass ratio w (PP SP179):...

Embodiment 1

[0028] The preparation process of Saike modified melamine formaldehyde resin, the specific steps are as follows:

[0029] First add 1 kg of hexamethoxymethyl melamine and 1.68 kg of sek to the kneader with heating device, start stirring and heat until sek is completely melted, then add 0.025 kg of p-toluenesulfonic acid, and heat the material to 150± React at 5°C for 4 hours, then cool to room temperature, pour the material out of the kneader, and pulverize it into a powder product with a pulverizer. The obtained product has a quality of 2.12kg, a mass yield of 79.1%, and a water solubility of 0.15g / 100mL of water. Product weight loss 2% (T 2wt% ), 5% (T5wt% ), 10% (T 10wt% ) temperature and the temperature T at the time of maximum thermogravimetric loss max They are 267°C, 298°C, 323°C and 345°C, respectively.

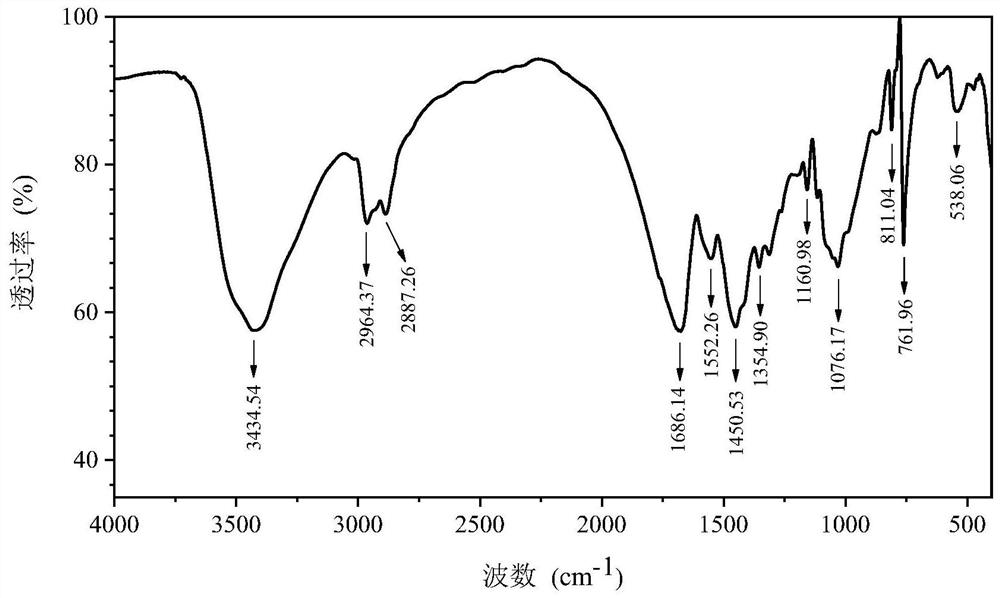

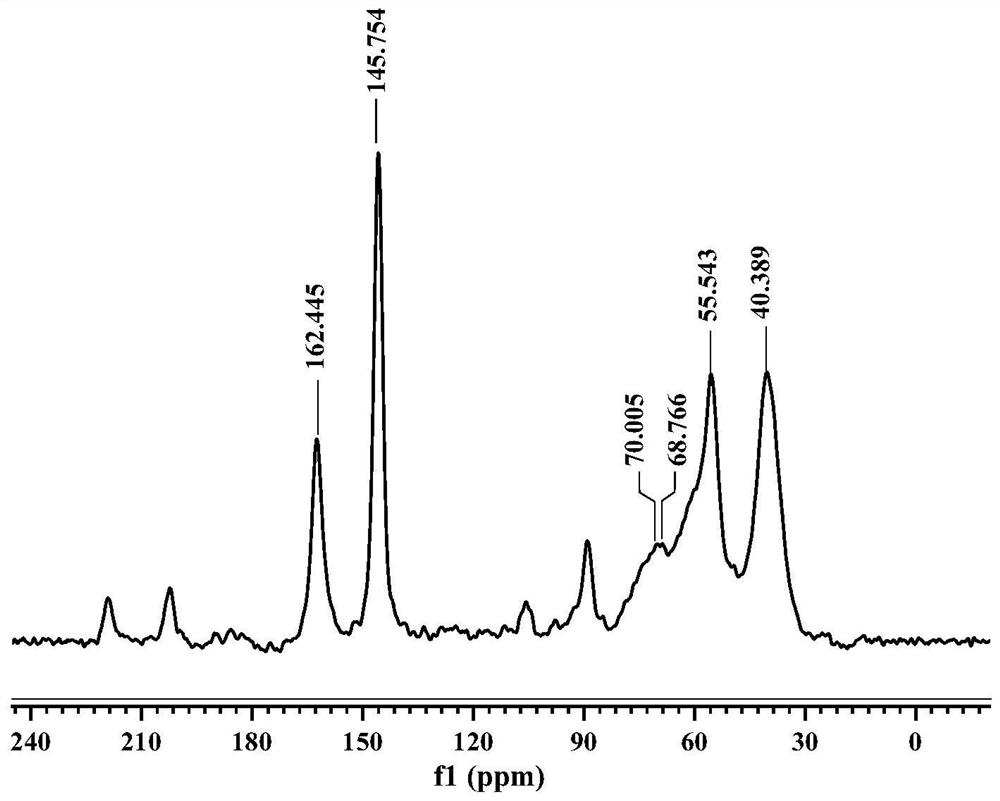

[0030] In the present invention, the structure of the product obtained in this embodiment is characterized by infrared spectroscopy and carbon nuclear magnetic re...

Embodiment 2

[0035] The preparation process of Saike modified melamine formaldehyde resin, the specific steps are as follows:

[0036] First, add 1 kg of hexamethoxymethylmelamine and 2.00 kg of Sek into the kneader with a heating device, start stirring and heat until the Sek is completely melted, then add 0.026 kg of p-toluenesulfonic acid, and heat the material to 150± React at 5°C for 4 hours, then cool to room temperature, pour the material out of the kneader, and pulverize it into a powder product with a pulverizer. The obtained product has a quality of 2.42kg, a mass yield of 80.7%, and a water solubility of 0.32g / 100mL of water. Product weight loss 2% (T 2wt% ), 5% (T 5wt% ), 10% (T 10wt% ) temperature and the temperature T at the time of maximum thermogravimetric loss max They are 263°C, 296°C, 320°C and 341°C, respectively.

[0037] The product of this example was detected according to the characterization method in Example 1, and it was proved that the product obtained in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com