Single-ion-conductor polymer electrolyte composite diaphragm as well as preparation method and application thereof

A conductor polymer and composite membrane technology, applied in batteries, circuits, electrospinning, etc., can solve the problems of weak film mechanical strength, low battery rate and cycle performance, to overcome poor mechanical properties, improve cycle performance, The effect of increasing the battery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A method for preparing a single-ion conductor polymer electrolyte composite diaphragm provided by the invention comprises the following steps:

[0037] Mix and disperse the single-ion conductor polymer electrolyte and the polymer matrix in a solvent to form a spinning solution, and use an electrospinning process to prepare a single-ion conductor polymer electrolyte composite membrane;

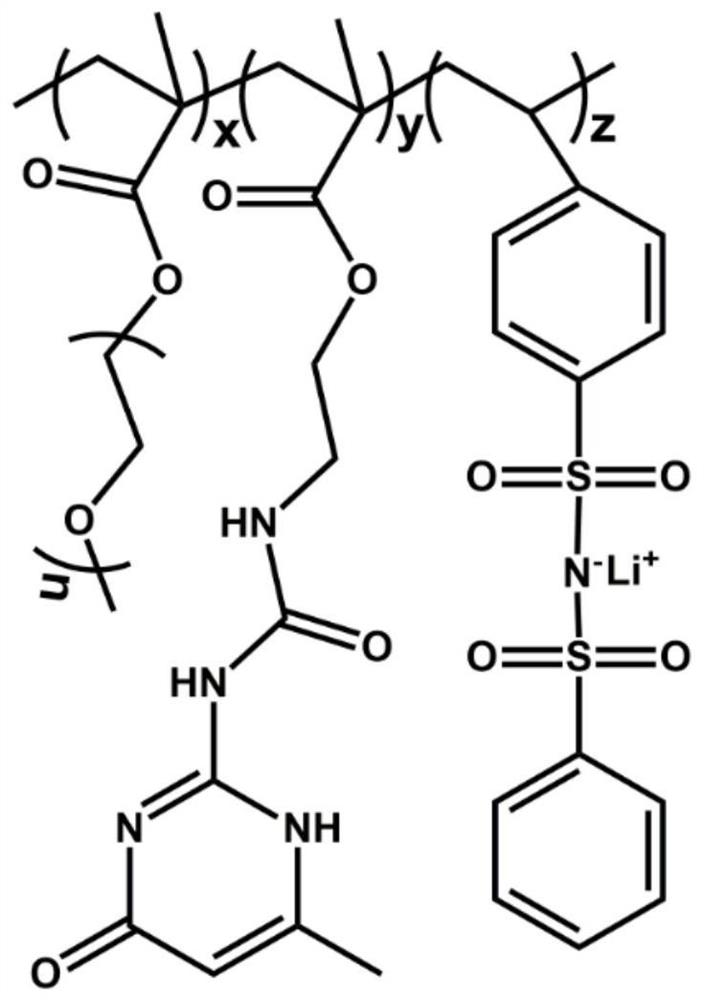

[0038] Wherein, the single ion conductor polymer electrolyte has a structural formula as shown in formula (1):

[0039]

[0040]In formula (1), x, y, z and n all take natural numbers, and x:y=100:10~10:100, x:z=100:10~10:100, n=3~20; The polymer matrix contains one or more elements of N, O and F.

[0041] The single-ion conductor polymer electrolyte of the present invention is composed of lithium styryl bissulfonylimide, UPyMA containing quadruple hydrogen bonds and polyethylene glycol monomethyl ether methacrylate through reversible addition - Obtained by fragmentation chain transf...

Embodiment 1

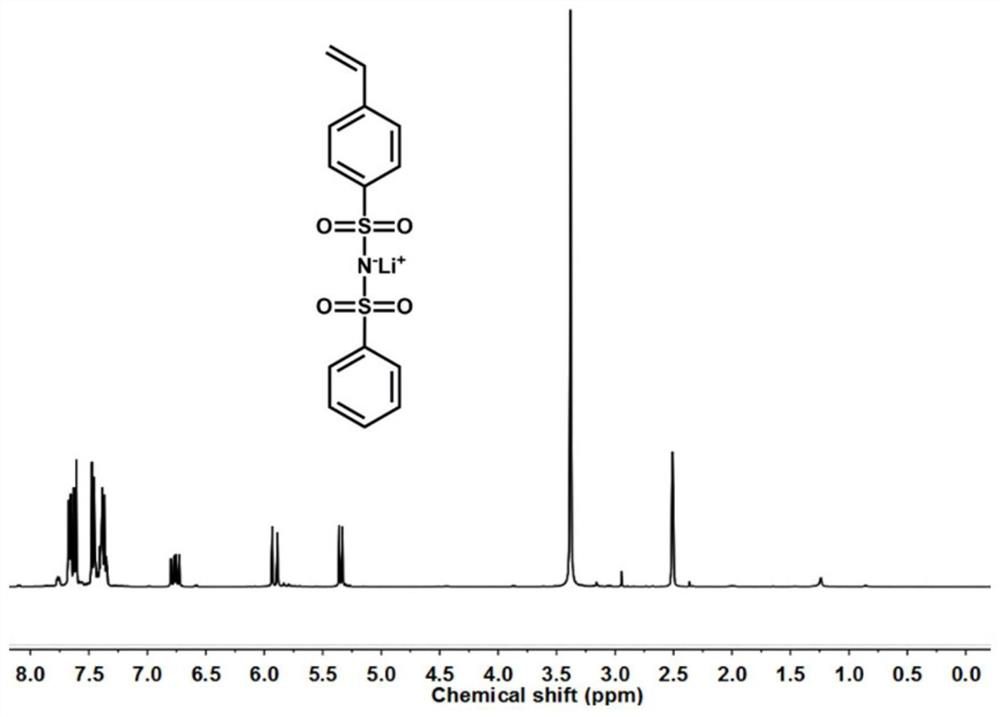

[0092] (1) Add 30mL of N,N-dimethylformamide into a 100mL two-neck round bottom flask, stir at 0°C for more than 30 minutes, then drop 25mL of thionyl chloride into N,N-dimethylformamide through a constant pressure dropping funnel. in methylformamide solution. Mechanical stirring was performed at 0°C under an inert atmosphere, and 0.05 mol of p-styrene sodium sulfonate solid powder was slowly added to the above solution. After the sodium p-styrenesulfonate was completely dissolved, it was stirred at 0°C under an inert atmosphere for 2 hours, then at room temperature under an inert atmosphere for 6 hours, and the obtained reaction solution was placed in a refrigerator at 4°C overnight. The reaction solution was dissolved in deionized water, extracted with dichloromethane, anhydrous MgSO 4 Drying, suction filtration, rotary evaporation, and drying gave p-styrenesulfonyl chloride, which was dissolved in anhydrous acetonitrile for later use.

[0093] (2) Dissolve 0.05mol benzene...

Embodiment 2

[0100] (1) According to the method of Example 1, the single-ion conductor polymer electrolyte shown in formula (1) was prepared, wherein x=100, y=20, z=40, n=9.

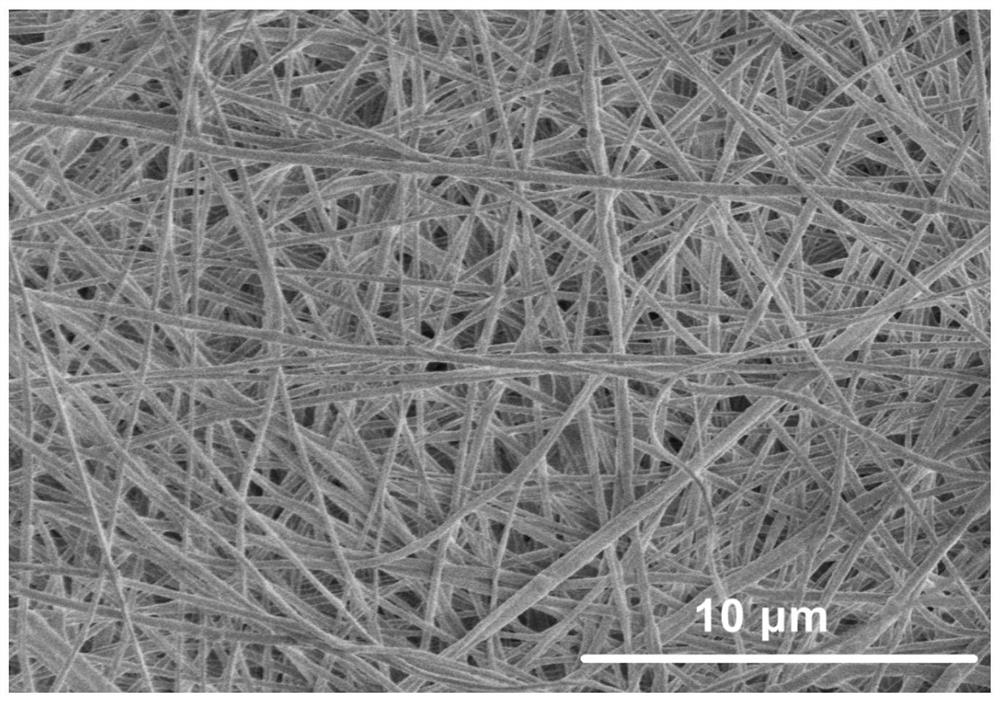

[0101] (2) Proportionally disperse the above-mentioned single ion conductor polymer electrolyte and polyvinylidene fluoride-hexafluoropropylene copolymer in a mixed solvent of N,N-dimethylformamide and acetone to prepare spinning solution, spinning solution The single-ion conductor polymer electrolyte composite diaphragm is prepared through an electrospinning process; the mass ratio of the single-ion conductor polymer electrolyte to polyvinylidene fluoride-hexafluoropropylene copolymer is 1:20; the electrospinning process parameters are: The spinning solution concentration is 12wt%, the spinning voltage is 17kV, the receiving distance is 15cm, and the jetting speed is 2.5mL / h.

[0102] The measured thickness of the single-ion conductor polymer electrolyte composite diaphragm is about 50 microns, and it is assembled i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com