Hexagonal boron nitride as well as preparation method and application thereof

A technology of hexagonal boron nitride and nitrogen compounds, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of increased system viscosity, low thermal conductivity, insufficient lubricity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

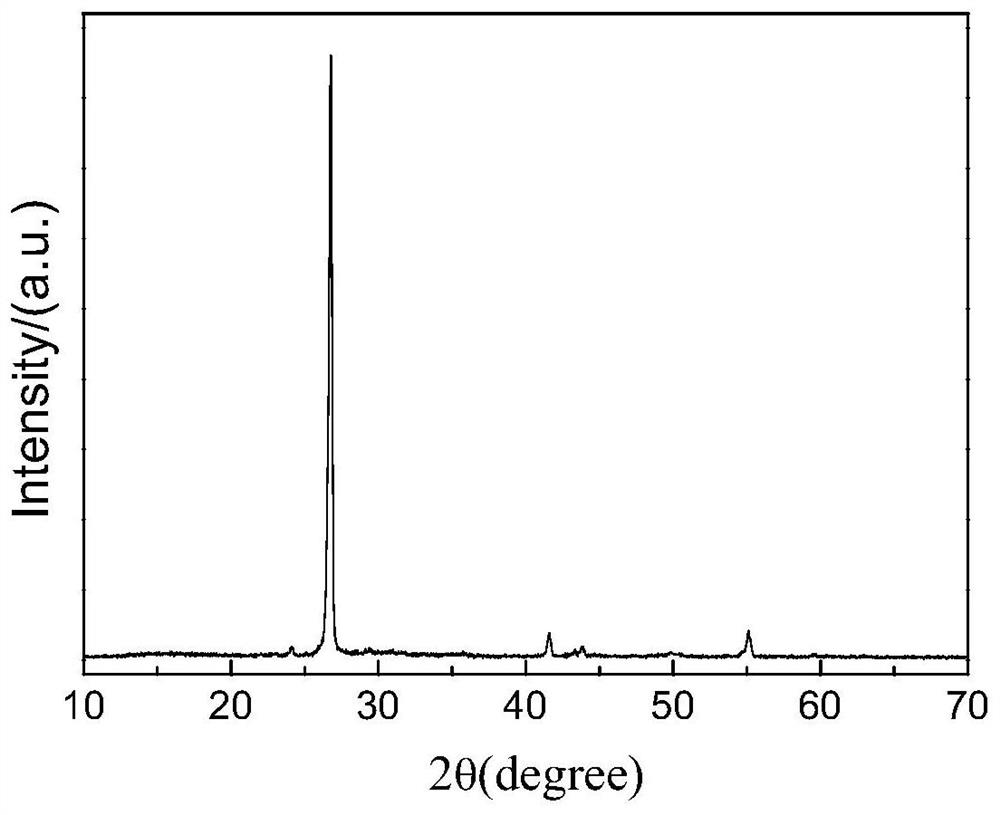

[0029] The invention provides a kind of preparation method of hexagonal boron nitride, comprises the following steps:

[0030] In a water vapor environment, the nitrogen-containing compound, the boron-containing compound and the crystallization aid are mixed and reacted to obtain a nitrogen-boron intermediate product containing the crystallization aid;

[0031] In a non-oxidizing atmosphere, sintering the nitrogen-boron intermediate product containing a crystallization aid to obtain the hexagonal boron nitride;

[0032] The crystallization aids include alkali metal borates, alkali metal carbonates, alkali metal nitrates, alkali metal sulfates, alkaline earth metal borates, alkaline earth metal carbonates, alkaline earth metal nitrates and alkaline earth metal sulfates. one or more of .

[0033] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0034] In the invention...

Embodiment 1

[0062] Add 55kg of metaboric acid, 45kg of ammeline and 5kg of calcium borate into the super mixer, feed flowing water vapor, keep the humidity in the tank at 80%, the temperature at 85°C, stir at 400rpm for 4 hours, and drying at 120° C. for 12 hours to obtain the nitrogen-boron intermediate product containing a crystallization aid;

[0063] The nitrogen-boron intermediate product was placed in an intermediate frequency induction tube furnace, and nitrogen gas (flow rate: 5 L / min) was introduced to carry out sintering (the heating rate was 10°C / min, the sintering temperature was 1900°C, and the temperature was kept for 8h) , cooled with the furnace to obtain a sintered block;

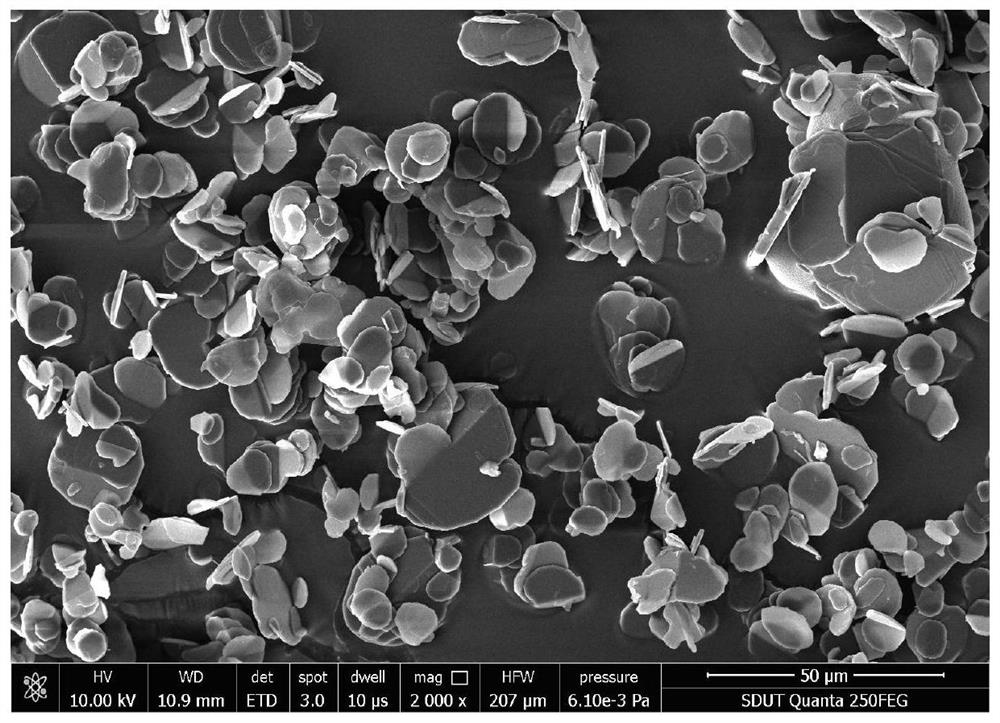

[0064] The sintered block is broken (rotating speed is 600rpm, the time is 20min) to 30cm 3 Finally, pulverize (rotating speed is 6000rpm, time is 20min) in the IKN high-shear pulverizer, obtains the powder (average particle diameter is 25 μm) that quality is 17kg;

[0065] The 17kg of powder was was...

Embodiment 2

[0068] Add 55kg of orthoboric acid, 45kg of melamine and 5kg of potassium borate into the super mixer, feed flowing water vapor, keep the humidity in the tank at 80%, the temperature at 85°C, stir at 400rpm for 4h, and dry at 120°C for 6h , obtaining the nitrogen-boron intermediate product containing a crystallization aid;

[0069] The nitrogen-boron intermediate product was placed in an intermediate frequency induction tube furnace, and nitrogen gas (flow rate: 5 L / min) was introduced to carry out sintering (the heating rate was 10°C / min, the sintering temperature was 1900°C, and the temperature was kept for 8h) , cooled with the furnace to obtain a sintered block;

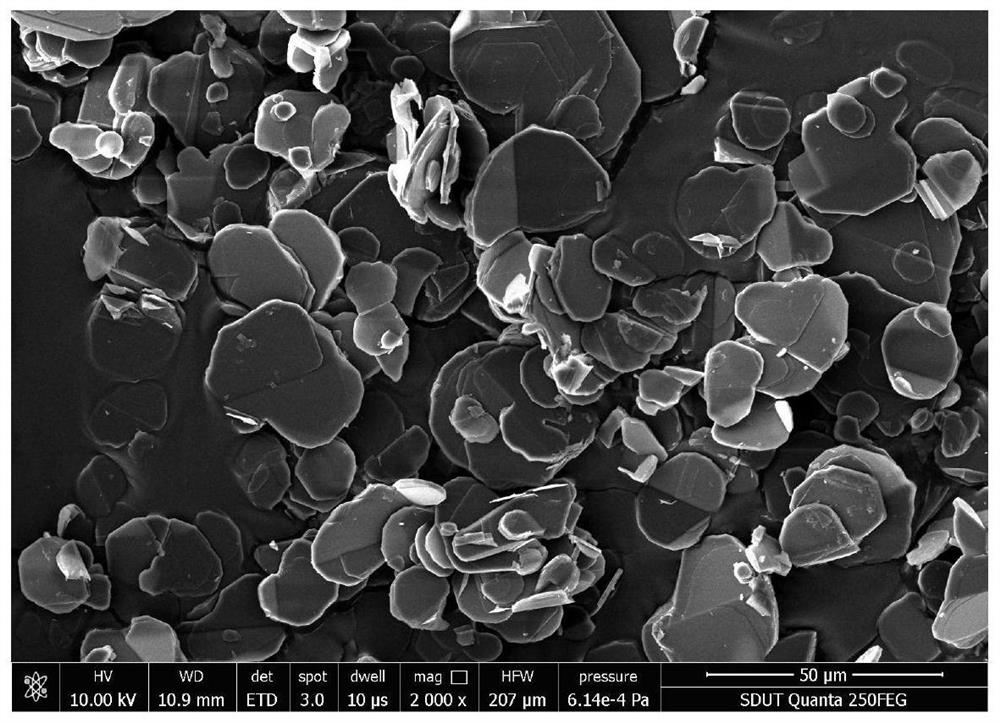

[0070] The sintered block is broken (rotating speed is 600rpm, the time is 20min) to 30cm 3 Finally, pulverize (rotating speed is 6000rpm, time is 20min) in the IKN high-shear pulverizer, obtains the powder (mean particle diameter is 50 μm) that quality is 16kg;

[0071] The 16kg of powder was washed with 500kg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com