Large-scale preparation method of sulfated kelp oligosaccharide suitable for cosmetics

A kelp oligosaccharide and sulfation technology, which is applied in the field of chemical extraction technology and cosmetics, can solve the problems of undiscovered sulfated kelp oligosaccharide preparation technology and process, which is not conducive to the absorption of kelp oligosaccharide, molecular weight distribution dispersion, etc., to avoid time Low cost and expensive consumables, good absorption, high concentration of molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

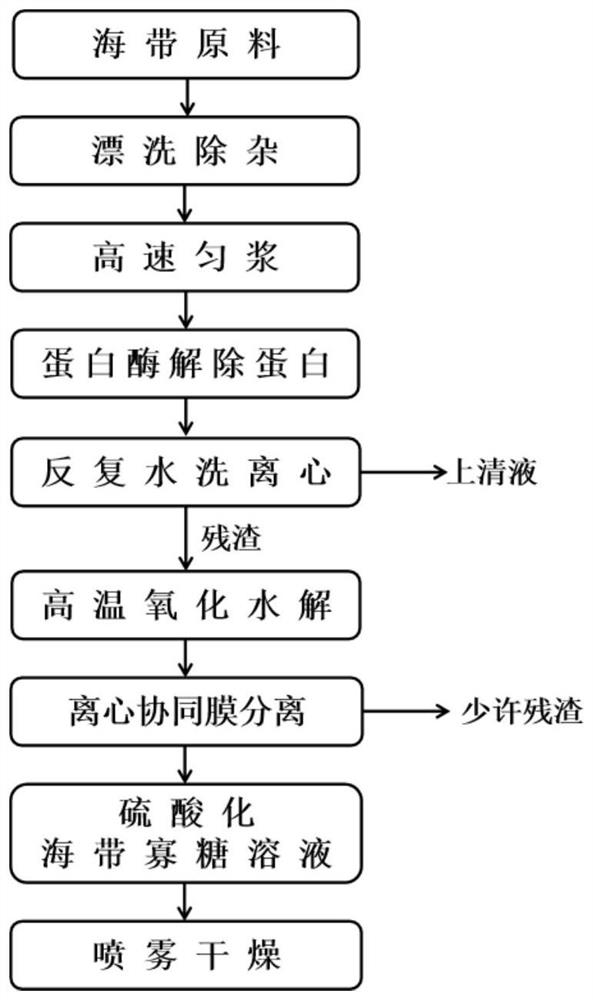

[0058] A large-scale preparation method of sulfated laminaria oligosaccharides suitable for cosmetics, the steps are as follows:

[0059] (1) Pretreatment

[0060] Put the kelp raw material into the reaction kettle, add a sodium bicarbonate solution 10 times the weight of the kelp, stir for 30 minutes, rinse with clean water, wherein the mass volume concentration of the sodium bicarbonate solution is 1%; put the washed kelp into the reaction kettle Add deionized water 10 times the weight of kelp, homogenate at high speed for 30 minutes, the homogenate speed is 16000 rpm, after the homogenization is completed, the temperature is raised to 55°C, the pH is adjusted to 6.5, and papain with 0.5% of the weight of kelp is added , reacted for 60 minutes; after enzymolysis, use a continuous flow centrifuge to centrifuge at a high speed at 14000rpm, collect the kelp residue after centrifugation and put it into the reactor again, add deionized water 10 times the weight of kelp, stir for ...

Embodiment 2

[0068] A large-scale preparation method of sulfated laminaria oligosaccharides suitable for cosmetics, the steps are as follows:

[0069] (1) Pretreatment

[0070] Put the kelp raw material into the reaction kettle, add potassium bicarbonate solution 5 times the weight of kelp, stir for 45 minutes, rinse with clean water, wherein the mass volume concentration of the potassium bicarbonate solution is 1%; put the washed kelp into the reaction kettle , add deionized water 5 times the weight of kelp, homogenate at a high speed for 60 minutes, the homogenate speed is 12000 rpm, after the homogenization is completed, the temperature is raised to 60 ° C, the pH is adjusted to 7.0, and papain with 0.5% of the weight of kelp is added React with 0.5% neutral protease for 45 minutes; after enzymolysis, use a continuous flow centrifuge to centrifuge at a high speed at 14,000rpm, collect the kelp residue after centrifugation and put it into the reactor again, add deionized water 15 times t...

Embodiment 3

[0078] A large-scale preparation method of sulfated laminaria oligosaccharides suitable for cosmetics, the steps are as follows:

[0079] (1) Pretreatment

[0080] Put the kelp raw material into the reaction kettle, add the sodium hydroxide solution 10 times the weight of the kelp, stir for 15 minutes, rinse with clean water, wherein the mass volume concentration of the sodium hydroxide solution is 4%; put the washed kelp into the reaction kettle , add deionized water 3 times the weight of kelp, homogenize at high speed for 60 minutes, the homogenization speed is 10000 rpm, after the homogenization is completed, the temperature is raised to 53 ° C, the pH is adjusted to 6.5, and papain with 1.0% of the weight of kelp is added React with 1.0% flavor protease for 30 minutes; after enzymolysis, use a continuous flow centrifuge to centrifuge at a high speed at 14,000rpm, collect the kelp residue after centrifugation and put it into the reactor again, add 15 times the weight of kel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com