Preparation method of hippophae rhamnoides and probiotic microcapsule and hippophae rhamnoides and probiotic microcapsule product prepared by preparation method

A technology of probiotics and microcapsules, which is applied in the field of seabuckthorn probiotic microcapsule products, can solve the problems of ineffective use of active ingredients, short probiotic activity retention time, and difficulty in ensuring probiotics, etc., to achieve the best proliferation effect , good enteric solubility, high content of live bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: Activation and proliferation of probiotic strains

[0037] In order to study the influence of different culture media on the activation of probiotics, the present invention uses different culture media to activate the probiotics, the details of which are as follows.

Embodiment 1-1

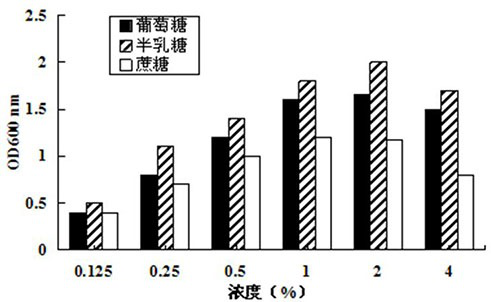

[0038] Embodiment 1-1: Selection of activation medium

[0039]Prepare 25 mL of glucose basal medium, galactose proliferation medium, and sucrose proliferation medium respectively; the carbon source concentration in each medium is set to six concentration gradients of 0.125%, 0.25%, 0.5%, 1.0%, 2.0%, and 4.0% After the preparation of the culture medium, it was sterilized at 121°C for 20 minutes.

[0040] The composition of the glucose basal medium is: peptone 10.0g / L, beef extract powder 5.0g / L, yeast extract powder 4.0g / L, glucose 20.0g / L, Tween-80 1.0ml / L, dipotassium hydrogen phosphate 2.0g / L, sodium acetate 5.0g / L, triammonium citrate 2.0g / L, magnesium sulfate 0.05g / L, the balance is water; the pH of the glucose basal medium is 6.2-6.4.

[0041] The composition of galactose proliferation medium is: peptone 10.0g / L, beef extract powder 5.0g / L, yeast extract powder 4.0g / L, galactose 20.0g / L, Tween-80 1.0mL / L, hydrogen phosphate Dipotassium 2.0g / L, sodium acetate 5.0g / L, tri...

Embodiment 1-2

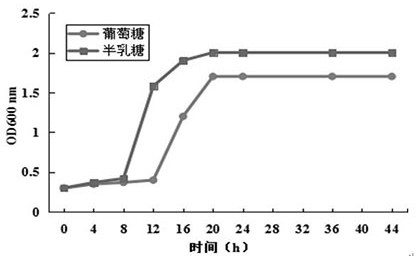

[0045] Embodiment 1-2: Effect of galactose proliferation medium on the growth process of probiotics

[0046] Prepare 25mL glucose basal medium (the concentration of glucose in the glucose medium is 2%) and galactose proliferation medium (the concentration of galactose in the galactose proliferation medium is 2%). Sterilize for 20 minutes. The preserved Lactobacillus bulgaricus and Bifidobacterium bifidum were inserted into each of the sterilized medium, and cultured anaerobically at 37° C. for 48 hours. The absorbance of the sterile solution was measured at 600 nm every 4 h. The absorbance measurement results were as figure 2 shown.

[0047] Depend on figure 2 It can be seen that the probiotics enter the logarithmic growth phase after being cultured in the galactose proliferation medium for 8 hours, and enter the logarithmic growth phase after being cultivated in the glucose-based medium for 12 hours. OD600 nm value was significantly higher than that of glucose basal me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com