Preparation method and application of porous hydrogel adsorbent based on astragalus mongholicus waste residue

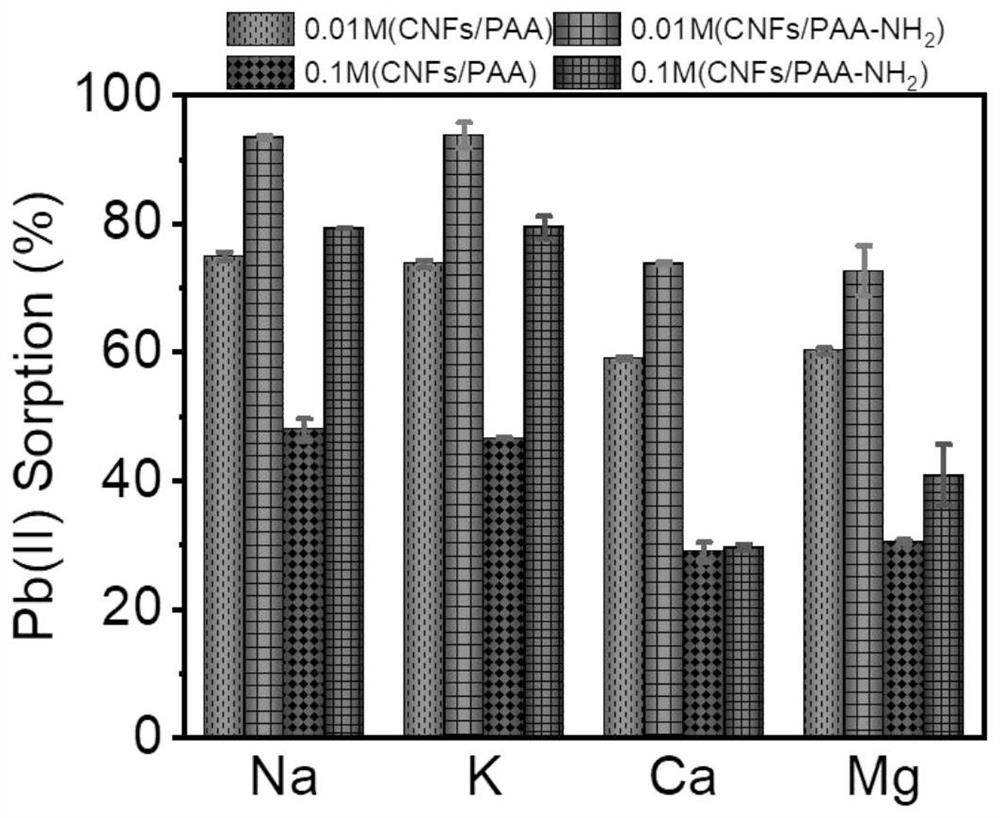

A porous hydrogel and adsorbent technology, applied in chemical instruments and methods, adsorption of water/sewage treatment, water pollutants, etc., can solve the problem that it is impossible to further synthesize porous hydrogel adsorbent materials, and it is difficult to effectively dissolve cellulose Precursor liquid, unfavorable gel system establishment and other problems, to achieve the effect of good reusability, excellent mechanical strength, and strong ability to resist ion interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

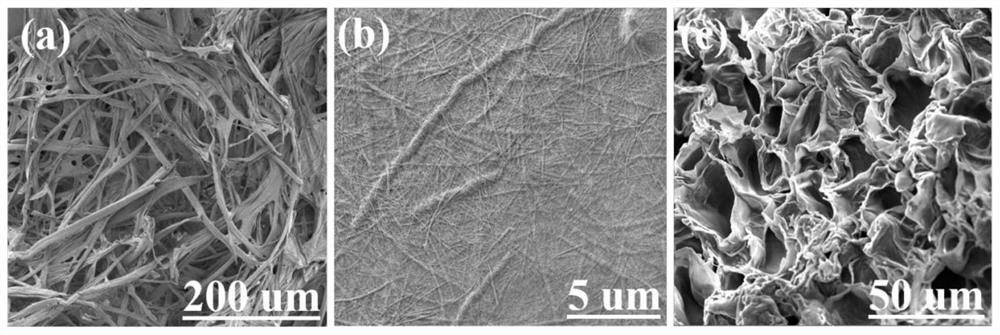

[0040] Embodiment 1: Preparation of cellulose nanofiber precursor (CNFs)

[0041] (1) NaClO 2 Bleaching: In order to dissolve the insoluble astragalus waste residue powder of different quality, first take 100mL NaClO with different mass concentrations of 1wt%, 5wt%, 8wt%, and 10wt%. 2 The solution was placed in four 250mL beakers, marked as I, II, III, and IV, and placed in four water baths in turn. The temperature of the water baths was adjusted to 75°C, and NaClO was added to the four beakers in turn. 2 The mass concentration of the solution corresponds to 0.5g, 5g, 8g, 10g of astragalus waste residue powder, and it is fully stirred for 3 to 4 hours;

[0042] (2) KOH alkali washing: After the yellow powder gradually turns white, take out the beaker, let it stand for 5 minutes, pour off the supernatant, and add 100mL to the 4 beakers in turn with a mass concentration of 1wt%, 5wt%, 8wt%, and 10wt%. KOH solution, adjust the temperature of the water bath to 90°C, and continue...

Embodiment 2

[0045] Example 2: Preparation of CNFs / PAA double network hydrogel adsorbent material

[0046] Take four 5mL centrifuge tubes, weigh about 20mg of N-N'methylenebisacrylamide (MBA) powder into each of the four centrifuge tubes, add 600 μL of acrylic acid monomer to the four centrifuge tubes with a pipette Dissolve the joint agent MBA, then take 3mL of CNFs solution from the high beakers I, II, III, and IV in the centrifuge tubes, and finally add 5mg of ammonium persulfate (APS) powder to the four centrifuge tubes in sequence, shake well to mix them Evenly, place 4 centrifuge tubes in an oven at 60°C for 4 hours to obtain 4 kinds of columnar CNFs / PAA double network hydrogel adsorbent materials, which are denoted as CNFs / PAA-1, CNFs / PAA-2, and CNFs / PAA -3. CNFs / PAA-4.

[0047] h 2 Preparation of O / PAA hydrogel material: Take a 5mL centrifuge tube, add 20mg N-N' methylenebisacrylamide (MBA) powder, 3mLH 2 O. 600 μL of acrylic acid (AA) monomer, 5 mg of ammonium persulfate (APS) ...

Embodiment 3

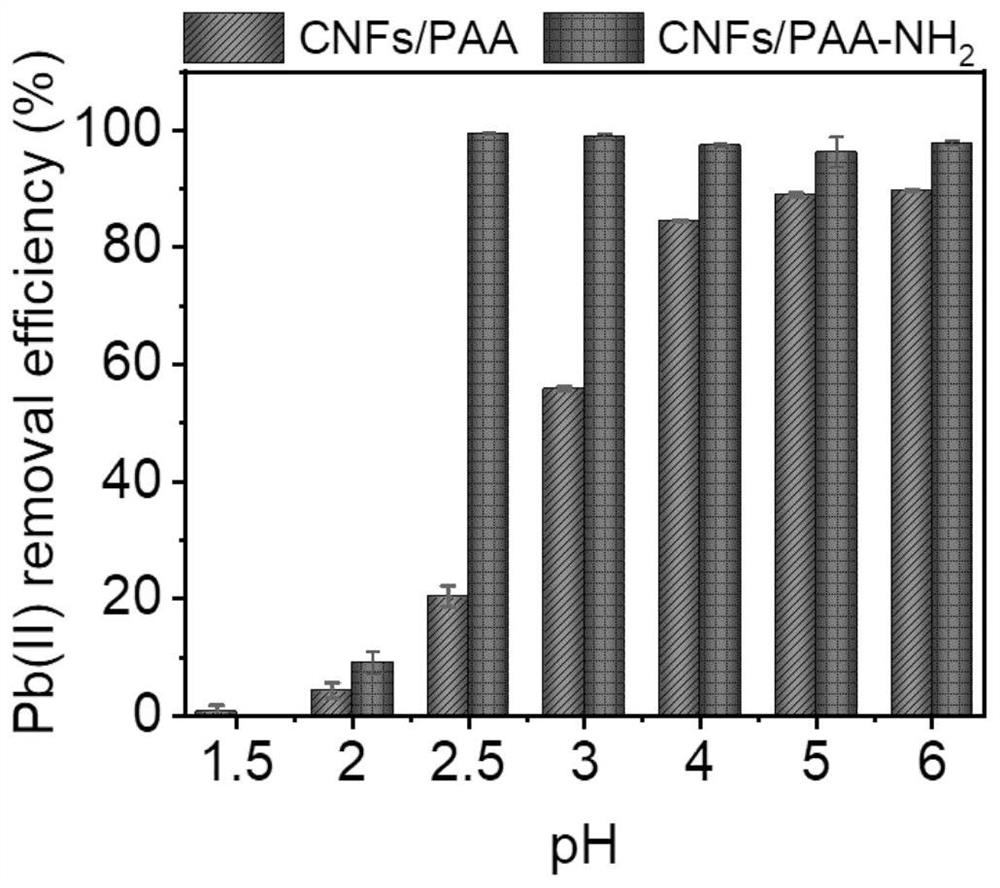

[0049] Example 3: NH 2 - Preparation of CNFs / PAA

[0050] Select CNFs / PAA with a cellulose content of 5wt% as the material to be modified, cut it into thin slices, and add it to the 2mLDMSO solution containing 0.1g NaOH and 0.15mL epichlorohydrin at a ratio of 2mLDMSO per 0.6mL , reacted at 60°C for 1h, after the reaction was completed, transferred it to 2mL NaOH aqueous solution containing 0.2mL triethylenetetramine with concentrations of 2wt%, 7wt%, 12wt%, 16wt%, and 20wt%, and reacted at 60°C for 2h , denoted as NH 2 -CNFs / PAA-1, NH 2 -CNFs / PAA-2, NH 2 -CNFs / PAA-3, NH 2 -CNFs / PAA-4, NH 2 -CNFs / PAA-5. The mechanical properties of the obtained material: NH 2 -CNFs / PAA-1>NH 2 -CNFs / PAA-2≈NH 2 -CNFs / PAA-3≈NH 2 -CNFs / PAA-4 >> NH 2 -CNFs / PAA-5. The adsorption capacity of the obtained material is 525 mg / g, 900 mg / g, 900 mg / g, 900 mg / g, 950 mg / g in sequence.

[0051]In summary, the following three points need to be paid attention to when preparing the dual network gel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com