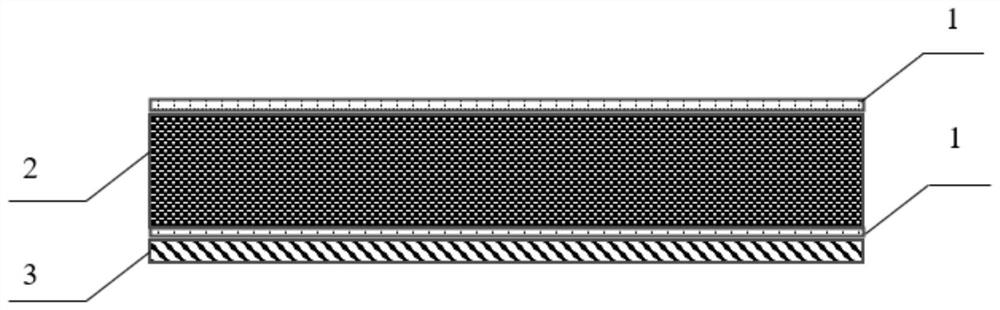

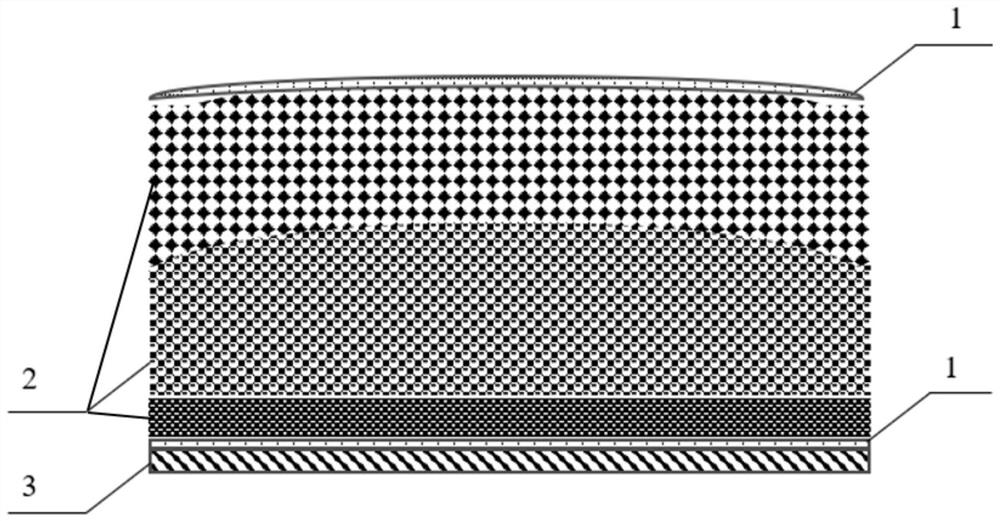

High-performance intumescent sandwich-structure ultrathin fireproof anticorrosive composite coating for steel structures and preparation method thereof

A composite coating and fire-resistant coating technology, applied in anti-corrosion coatings, fire-resistant coatings, coatings, etc., can solve the problems of general fire resistance, lack of anti-corrosion performance, and fire site injury, etc., to increase surface strength and tortoise resistance. cracking performance, excellent synergistic flame retardant and smoke suppression effects, and the effect of reducing smoke generation and heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Step 1: Mix 5 parts of methyltrimethoxysilane, 5 parts of γ-(2,3-glycidoxy)propyltrimethoxysilane, 20 parts of methyltriethoxysilane siloxane, 0.3 parts of acetic acid Portions are mixed, stirring. Add 7 parts of propylene glycol butyl ether, dropwise add 40 parts of nano-silica sol, and stir. Then add 10 parts of titanium dioxide, 5 parts of aluminum oxide whiskers, and 5 parts of mica powder, grind and disperse with a ball mill, add leveling agent and defoamer after taking it out, and obtain silicone ceramic coating.

[0078] Step 2: compound ammonium polyphosphate, pentaerythritol, melamine and melamine borate in a mass ratio of 25:10:13:2 to prepare an intumescent flame retardant (IFR). Take 50 parts of IFR, add 10 parts of flame retardant MCA, 1 part of nano-silica sol, 60 parts of deionized water, 0.5 parts of wetting and dispersing agent, and 0.5 parts of leveling agent into a sand mill dispersing multipurpose machine and stir at high speed for 20 minutes. Add ...

Embodiment 2

[0083] Step 1: Mix 5 parts of methyltrimethoxysilane, 5 parts of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, 25 parts of methyltriethoxysilanesilane, 0.3 parts of acetic acid Portions are mixed, stirring. Add 7 parts of propylene glycol butyl ether, dropwise add 40 parts of nano-silica sol, and stir. Then add 10 parts of titanium dioxide, 5 parts of aluminum oxide whiskers, and 5 parts of mica powder, grind and disperse with a ball mill, add leveling agent and defoamer after taking it out, and obtain silicone ceramic coating.

[0084]Step 2: Ammonium polyphosphate, pentaerythritol, melamine and melamine borate are compounded in a mass ratio of 25:10:13:2 to prepare an intumescent flame retardant (IFR). Take 50 parts of IFR, then add 15 parts of MCA, 1 part of nano-silica sol, 60 parts of deionized water, 1 part of wetting and dispersing agent, and 1 part of leveling agent into a sand mill dispersing multipurpose machine and stir at high speed for 20 minutes. Add 25 parts of ...

Embodiment 3

[0087] Step 1: Mix 5 parts of methyltrimethoxysilane, 5 parts of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, 15 parts of methyltriethoxysilanesilane, 0.3 parts of acetic acid Portions are mixed, stirring. Add 3 parts of propylene glycol butyl ether, dropwise add 30 parts of nano-silica sol, and stir. Then add 10 parts of titanium dioxide, 2.5 parts of aluminum oxide whiskers, and 2.5 parts of mica powder, grind and disperse with a ball mill, add leveling agent and defoamer after taking it out, and obtain silicone ceramic coating.

[0088] Step 2: Ammonium polyphosphate, pentaerythritol, melamine and melamine borate are compounded in a mass ratio of 25:10:13:2 to prepare an intumescent flame retardant (IFR). Take 50 parts of IFR, then add 10 parts of MCA, 1 part of nano-silica sol, 60 parts of deionized water, 0.5 parts of wetting and dispersing agent, and 0.5 parts of leveling agent into the sand mill dispersing multipurpose machine and stir at high speed for 20 minutes. Add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com