Organic metal solderability preservative and preparation method and application oforganic metal solderability preservative film

An organometallic and flux-preserving technology used in metallurgical bonding, printed circuit manufacturing, and assembling printed circuits with electrical components. Impact performance, does not affect welding performance, and improves the effect of oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

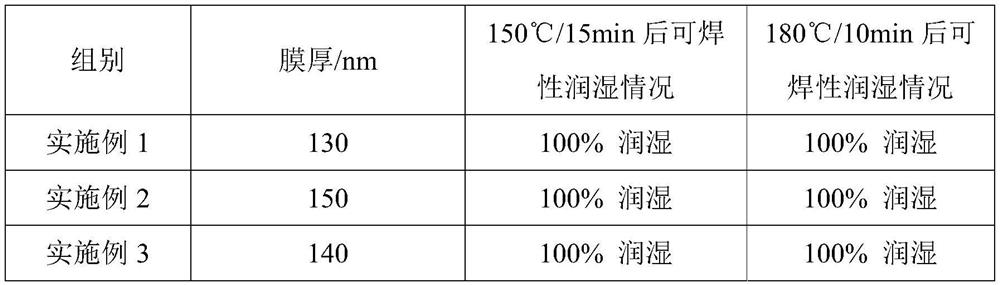

Embodiment 1

[0030] Embodiment 1, a kind of preparation method of organometallic solder protection flux and organometallic solder protection film

[0031] The organic metal flux includes the following components and parts by weight thereof:

[0032] 20 parts of thiazole derivatives, 10 parts of imidazole derivatives, 8 parts of nitrogen azole derivatives, 5 parts of sodium secondary alkyl sulfate, 28 parts of malic acid, 20 parts of tartaric acid, 10 parts of ethanol, and 150 parts of water.

[0033] The thiazole derivatives in the organometallic flux are composed of aryl-substituted thiazole and 5-benzylthio-1,3,4-thiadiazole-2-thiol in a mass ratio of 13:2.

[0034] The imidazole derivatives in the organometallic flux are composed of 2-hydroxybenzimidazole, 1-(4-aminophenyl)imidazole and N-acetylimidazole in a mass ratio of 7:11:4.

[0035] The azole derivatives in the organometallic flux are composed of tolyltriazole, 4,5-dibromo-1H-benzotriazole and 5-amino-3-mercapto-1,2,4 - Triazol...

Embodiment 2

[0044] Embodiment 2, a kind of preparation method of organic metal solder protection flux and organic metal solder protection film

[0045] The organic metal flux includes the following components and parts by weight thereof:

[0046] 30 parts of thiazole derivatives, 15 parts of imidazole derivatives, 13 parts of nitrogen azole derivatives, 8 parts of sodium secondary alkyl sulfate, 35 parts of malic acid, 30 parts of tartaric acid, 15 parts of ethanol, and 200 parts of water.

[0047] The thiazole derivatives in the organometallic flux are composed of aryl-substituted thiazole and 5-benzylthio-1,3,4-thiadiazole-2-thiol in a mass ratio of 15:4.

[0048] The imidazole derivatives in the organometallic flux are composed of 2-hydroxybenzimidazole, 1-(4-aminophenyl)imidazole and N-acetylimidazole in a mass ratio of 3:9:2.

[0049] The azole derivatives in the organometallic flux are composed of tolyltriazole, 4,5-dibromo-1H-benzotriazole and 5-amino-3-mercapto-1,2,4 - Triazole ...

Embodiment 3

[0058] Embodiment 3, a kind of preparation method of organic metal solder protection flux and organic metal solder protection film

[0059] The organometallic flux includes the following components and parts by weight: 26 parts of thiazole derivatives, 12 parts of imidazole derivatives, 11 parts of nitrogen azole derivatives, 6.3 parts of secondary alkyl sodium sulfate, 27 parts of malic acid 24.5 parts of tartaric acid, 12.6 parts of ethanol, and 178 parts of water.

[0060] The thiazole derivatives in the organometallic flux are composed of aryl-substituted thiazole and 5-benzylthio-1,3,4-thiadiazole-2-thiol in a mass ratio of 14:3.

[0061] The imidazole derivatives in the organometallic flux are composed of 2-hydroxybenzimidazole, 1-(4-aminophenyl)imidazole and N-acetylimidazole in a mass ratio of 5:10:3.

[0062] The azole derivatives in the organometallic flux are composed of tolyltriazole, 4,5-dibromo-1H-benzotriazole and 5-amino-3-mercapto-1,2,4 - Triazoles are compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com