Composite negative plate and lithium ion battery comprising same

A technology of negative electrode and negative electrode, which is applied in the field of composite negative electrode and lithium ion battery containing the negative electrode, can solve the problems of difficult to obtain rate and cycle performance, poor rate or cycle performance, and poor stability, so as to improve the rate and Effects of cycle performance, improvement of lithium ion conductivity, and improvement of mutual compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

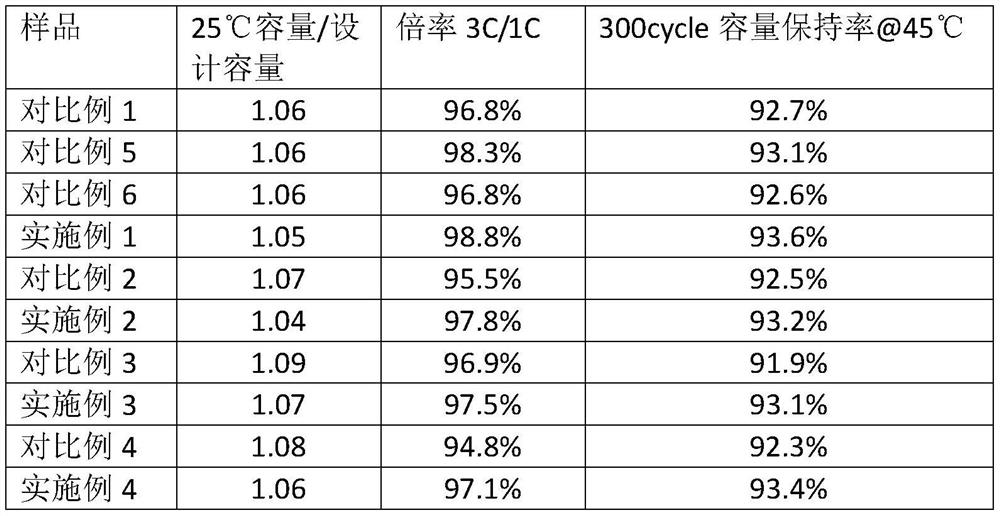

Examples

Embodiment 1

[0024] (1) Preparation of positive electrode sheet: 96g of lithium iron phosphate, 0.3g of graphene, 1.5g of carbon black, 0.2g of carbon nanotubes, 2g of polyvinylidene fluoride, 65g of N-N-dimethylpyrrolidone, fully stirred and dispersed to form a slurry, Evenly coated on the calendered aluminum foil of the positive electrode current collector, rolled after drying to make the positive electrode sheet.

[0025] (2) Prepare the inner layer of the negative electrode sheet: 94.5g of artificial graphite, 1.5g of carbon black, 1.5g of sodium carboxymethyl cellulose, 2.5g of styrene-butadiene rubber, 120g of deionized water, stir to form a slurry, and evenly coat the negative electrode The current collector is placed on the electrolytic copper foil, and rolled after drying.

[0026] Outer layer: 93g of soft carbon, 1g of Li2S-P2S5, 2.5g of carbon black, 2g of sodium carboxymethyl cellulose, 2.5g of styrene-butadiene rubber, 180g of deionized water, stirred to form a slurry, and eve...

Embodiment 2

[0029] (1) Preparation of positive electrode sheet: 96g of lithium iron phosphate, 0.3g of graphene, 1.5g of carbon black, 0.2g of carbon nanotubes, 2g of polyvinylidene fluoride, 65g of N-N-dimethylpyrrolidone, fully stirred and dispersed to form a slurry, Evenly coated on the calendered aluminum foil of the positive electrode current collector, rolled after drying to make the positive electrode sheet.

[0030] (2) Preparation of negative pole piece

[0031] Inner layer: 88g of artificial graphite, 4.5g of carbon nanotubes, 3g of sodium carboxymethyl cellulose, 4.5g of polyvinylidene fluoride, 120g of deionized water, stirred to form a slurry, and evenly coated on the negative electrode current collector electrolytic copper foil, Roll pressing after drying.

[0032] Outer layer: Lithium titanate 86g, Li2S-SiS2 0.5g, graphene 4.5g, sodium carboxymethyl cellulose 4.5g, polyurethane 4.5g, deionized water 180g, stir to form a slurry, evenly coated on the inner layer of the negat...

Embodiment 3

[0035] (1) Preparation of positive electrode sheet: 96g of lithium iron phosphate, 0.3g of graphene, 1.5g of carbon black, 0.2g of carbon nanotubes, 2g of polyvinylidene fluoride, 65g of N-N-dimethylpyrrolidone, fully stirred and dispersed to form a slurry, Evenly coated on the calendered aluminum foil of the positive electrode current collector, rolled after drying to make the positive electrode sheet.

[0036] (2) Prepare the inner layer of the negative pole piece: 98.6g of artificial graphite, 0.4g of carbon fiber, 0.5g of polyvinylpyrrolidone, 0.5g of polyacrylic acid, 120g of deionized water, stir to form a slurry, and evenly coat the electrolytic copper foil on the negative current collector On, roll after drying.

[0037]Outer layer: lead telluride 98.6g, Li2S-B2S3 2g, conductive graphite 0.4g, polyvinylpyrrolidone 0.5g, polysodium alginate 0.5g, deionized water 180g, stir to form a slurry, evenly coated on the inner layer of the negative electrode On the sheet, the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer layer thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com