A high-efficiency antiscaling and dispersing agent for reverse osmosis membrane

A scale inhibitor and dispersant, reverse osmosis membrane technology, used in semi-permeable membrane separation, membrane technology, scale removal and water softening, etc. Improves water solubility, weakens bridging, and inhibits homogeneous nucleation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

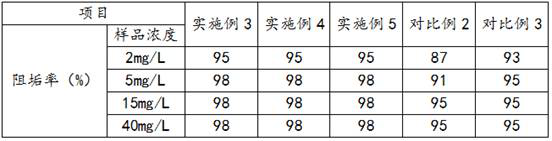

Examples

Embodiment 1

[0029] Preparation of antimicrobial components:

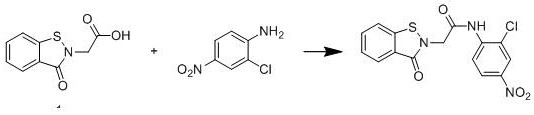

[0030] Step S11, mix potassium hydroxide and deionized water, then add dropwise an aqueous solution of 1,2-benzisothiazol-3-one, and dropwise add an aqueous solution of chloroacetic acid at a temperature of 0° C. The temperature was raised to 90°C, and the reaction was stirred for 4 hours. After the reaction, the temperature of the reaction solution was lowered to room temperature, concentrated under reduced pressure to remove the solvent, and then dried to constant weight at 40°C under vacuum to obtain Intermediate 1;

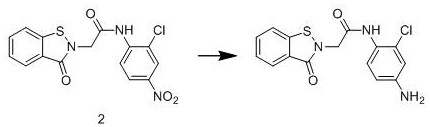

[0031] Step S12, mixing intermediate 1, N,N-dimethylformamide and 2-chloro-4-nitroaniline, adding 1-hydroxybenzotriazole and 1-ethyl-3(3 -Dimethylpropylamine) carbodiimide, stirred and reacted at room temperature for 20h, after the reaction was over, mixed the obtained reaction solution with deionized water, then filtered under reduced pressure, the filter cake was washed with deionized water, and the washing w...

Embodiment 2

[0035] Preparation of antiscalant components:

[0036] Step A11, mix acrylic acid and deionized water, then add aqueous sodium hydroxide solution, adjust the pH value to 6 to obtain a mixed solution, mix the obtained mixed solution with chitosan, and stir and react for 5 hours at a temperature of 90°C , after the reaction, adjust the pH value to 10 with sodium hydroxide, then centrifuge, retain the supernatant, add 2 times the volume of ethanol solution with a volume fraction of 95% to the supernatant, vacuum suction filtration, filter cake with washing with absolute ethanol, and drying to constant weight under vacuum at 70°C after washing to obtain intermediate a;

[0037] Step A12, mix the intermediate a and methanol, then add the antibacterial component, stir and react at 25°C for 72h, after the reaction, filter the obtained reaction solution under reduced pressure, and then dry at 40°C to constant weight , to obtain intermediate b;

[0038] Step A13, mix intermediate b, ...

Embodiment 3

[0041] Preparation of antiscalant dispersant:

[0042] The first step is to mix acrylic acid and deionized water, then adjust the pH value to 7 with a 20% aqueous sodium hydroxide solution by mass fraction, and then add allyl sodium sulfonate to obtain a mixed monomer solution;

[0043] The second step is to mix the anti-scaling component and deionized water, and stir for 1 hour under nitrogen protection at a temperature of 65°C, then add ammonium persulfate at a temperature of 55°C, and then add the mixed monomer solution dropwise , after the dropwise addition, continue to stir the reaction for 3h. After the reaction, the obtained reaction solution is precipitated with acetone, filtered with suction, and the filter cake is washed with absolute ethanol. After the washing is completed, it is dried to a constant weight under vacuum at 60°C. A high-efficiency scale-inhibiting dispersant for reverse osmosis membranes is obtained.

[0044] Among them, the amount ratio of acrylic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com