Nitride high electron mobility transistor and manufacturing method thereof

A technology with high electron mobility and transistors, applied in the fields of electric solid-state devices, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of difficult precise control of etching process, low completeness and success rate of device peeling, and rough and uneven peeling interface To achieve the effect of improving device current and power output characteristics, avoiding lattice mismatch and thermal mismatch problems, improving switching current ratio and breakdown characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

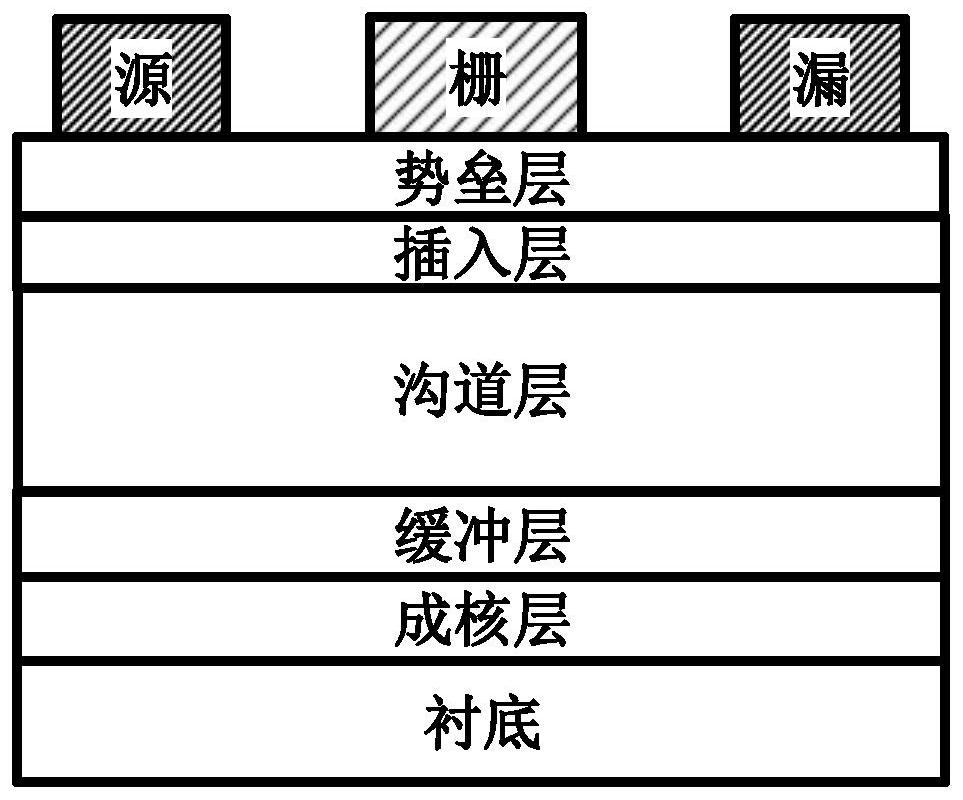

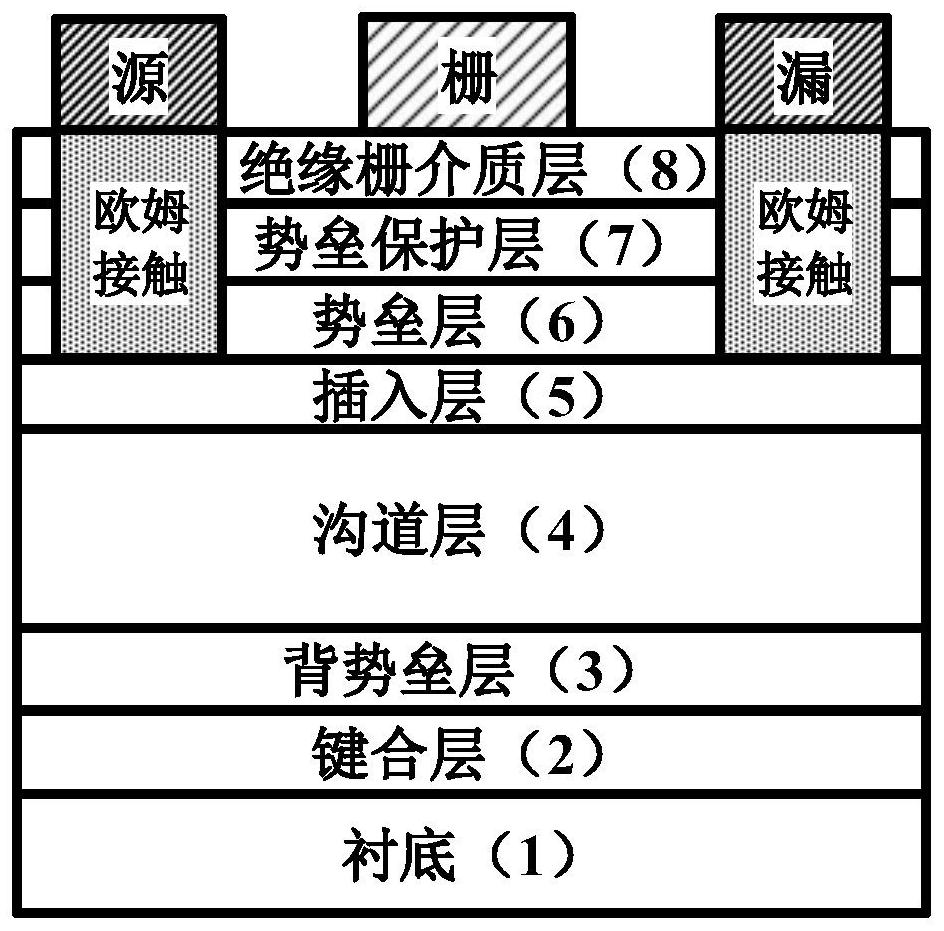

[0068] EXAMPLES First, a diamond-based nitride high electron mobility transistor using a SiN bonding layer, a GaN channel layer, and an AlGa barrier layer is produced.

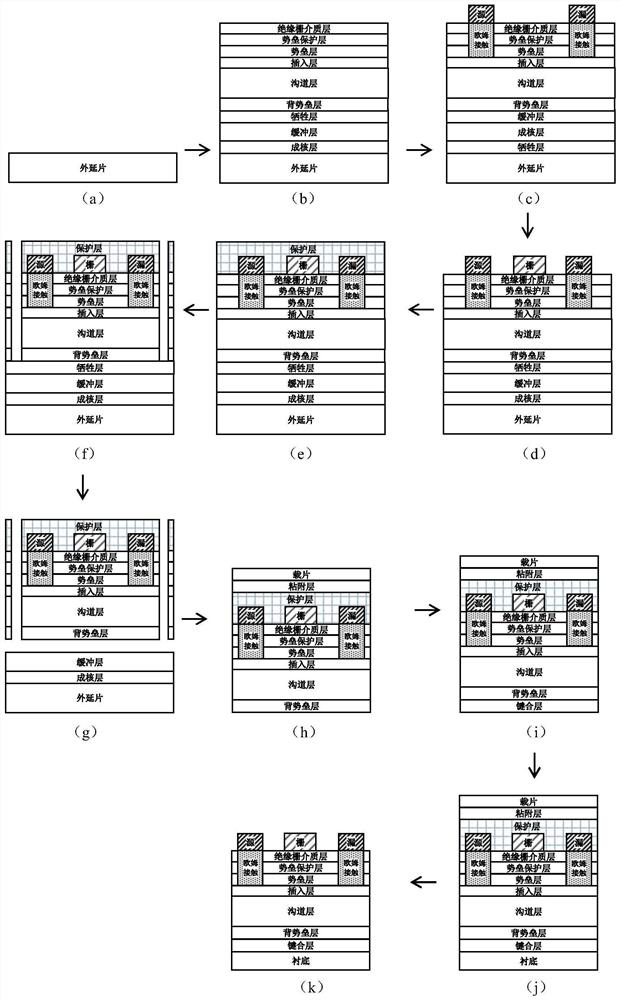

[0069] Step 1. Select sapphire epitaxial sheet as auxiliary epitaxial substrate, such as image 3 (a).

[0070] Step 2, in the sapphire epitaxial sheet, the AlN nucleation layer, GaN buffer layer, ALPN sacrificial layer, AlGan back stop layer, GaN channel layer, AlGa barrier layer, GaN barrier protective layer and Al 2 O 3 Insulated gate dielectric layer, such as image 3 (b).

[0071] 2. 1) A hydraulic layer using metal organic chemical gas phase deposition techniques on the sapphire epitaxial film, the process conditions used by the Aln nucleation layer, the process conditions employed by the Aln nucleation layer: the temperature is 1100 ° C, the pressure is 40 torr, the ammonia gas flow is 2000sccm, aluminum source of 20 sccm, hydrogen flow rate of 3000 sccm;

[0072] 2.2) A GaN buffer layer having a thickness of...

Embodiment 2

[0100] Embodiment 2, a metal copper-based nitride high electron mobility transistor using a Ti / Au bonding layer, an INGAN channel layer, and an INALN barrier layer.

[0101] Step 1, use silicon carbide epitaxial sheet, as an auxiliary epitaxial substrate, such as image 3 (a).

[0102] Step 2, in the silicon carbide epitaxial sheet, the AlN nucleation layer, GaN buffer layer, AlPn sacrificial layer, AlGan back stop layer, INGAN channel layer, INALN barrier layer, AlN barrier protective layer and HFO 2 Insulated gate dielectric layer, such as image 3 (b).

[0103] 2A) Use metal organic chemical gas phase deposition techniques, at a temperature of 1200 ° C, the pressure is 40 torr, the ammonia gas flow is 2000 sccm, the aluminum source is 20sccm, and the hydrogen flow is 3000 SCCM, the hydrogen carbide is deposited on silicon carbide. ALN-based nuclear layer having a thickness of 140 nm;

[0104] 2b) Use metal organic chemical vapor deposition techniques, at a temperature of 1200 °...

Embodiment 3

[0126] Embodiment 3 produced using Si bonding layer, a diamond-based nitride high electron mobility transistor InN ScAlN channel layer and barrier layer.

[0127] Step A, the choice of epitaxial wafers, the epitaxial substrate as an auxiliary, such as image 3 (a).

[0128] Procedure B, are sequentially grown on the silicon wafer bottom-AlN, AlGaN, AlN / AlGaN superlattice composite nucleation layer, GaN buffer layer, AlPN sacrificial layer, AlGaN barrier backing layer, GaN channel layer, ScAlN barrier layer, AlN layer and the protective barrier Al 2 O 3 Insulated gate dielectric layer, such as image 3 (b).

[0129] B1) using a metal organic chemical vapor deposition technique, a temperature of 1150 ℃, a pressure of 40 Torr, flow rate of 2000 sccm of ammonia, aluminum source flow rate of 20 sccm, 90 sccm flow rate of the gallium source, the hydrogen gas flow rate of 3000sccm process conditions, epitaxial silicon deposited in a thickness on sheet based on AlN, AlGaN, AlN / AlGaN sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com