Wide-range pressure sensor chip and monolithic integration preparation method thereof

A pressure sensor and monolithic integration technology, applied in the field of MEMS sensors, can solve problems such as difficulty in adapting to pressure detection, difficulty in ensuring repeatability and consistency, and small pressure measurement range of pressure sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The specific steps of a monolithic integrated preparation method for a wide-range pressure sensor chip are as follows:

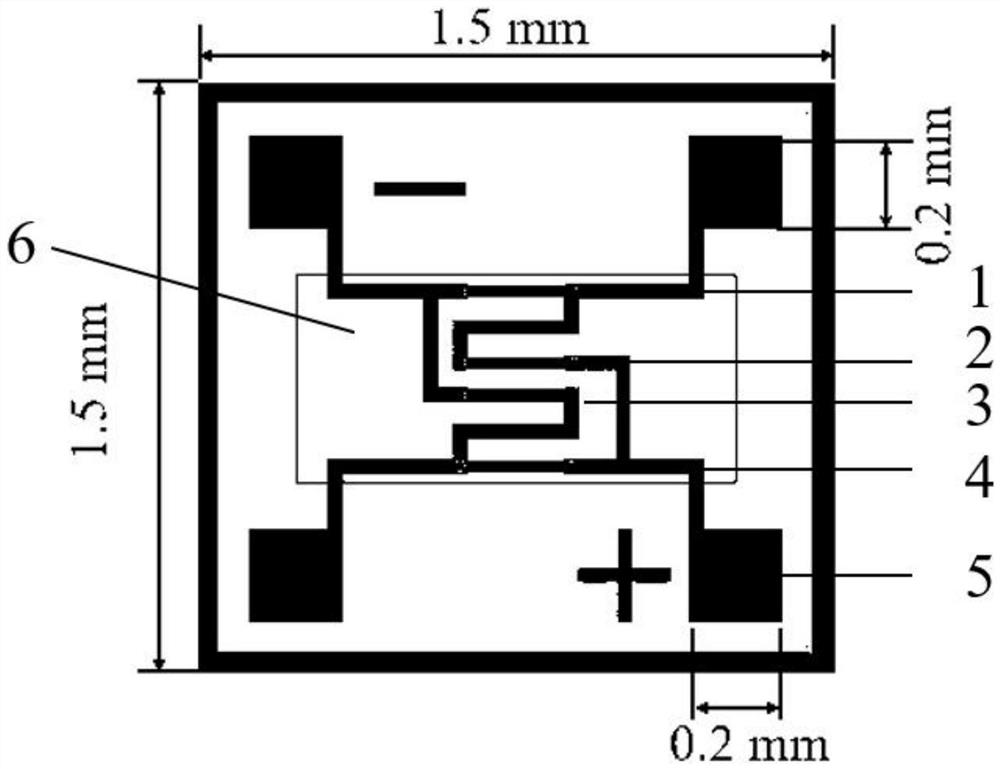

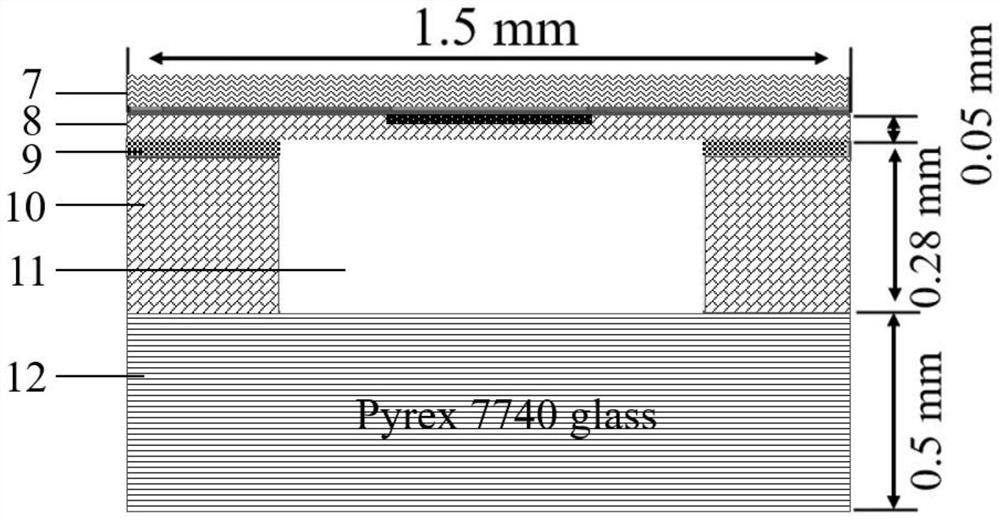

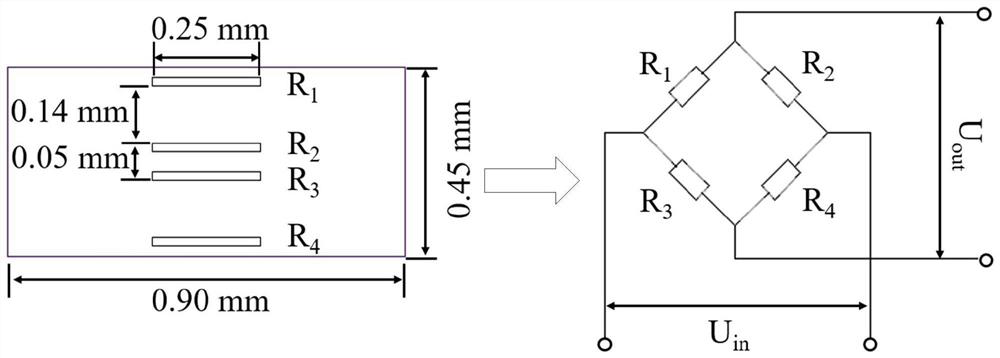

[0067] S1: Using SOI as the substrate, using photolithography, ion implantation, plasma enhanced chemical vapor deposition (PECVD), reactive ion etching (RIE), spin coating, evaporative deposition, wet etching and stripping and other micromachining processes to form Planar structures such as piezoresistive (1, 2, 3, 4), pads and interconnection lines (5) and passivation layer (7);

[0068] S2: Use double-side alignment photolithography, deep silicon etching on the back, RIE etching of the buried oxide layer, and silicon-glass anode bonding process on the back to form the back chamber of the pressure sensor.

[0069] The specific process of step S1 is as follows:

[0070] 1) if Pic 4-1 As shown, using an SOI silicon wafer as a substrate, the SOI was ultrasonically cleaned in acetone, ethanol, and deionized water for 5 minutes, dried with nitrogen, a...

Embodiment 2

[0086] The specific steps of a monolithic integrated preparation method for a wide-range pressure sensor chip are as follows:

[0087] S1: Using SOI as the substrate, using photolithography, ion implantation, plasma enhanced chemical vapor deposition (PECVD), reactive ion etching (RIE), spin coating, evaporative deposition, wet etching and stripping and other micromachining processes to form Planar structures such as piezoresistive (1, 2, 3, 4), pads and interconnection lines (5) and passivation layer (7);

[0088] S2: Use double-side alignment photolithography, deep silicon etching on the back, RIE etching of the buried oxide layer, and silicon-glass anode bonding process on the back to form the back chamber of the pressure sensor.

[0089] The specific process of step S1 is as follows:

[0090] 16) Using an SOI silicon wafer as a substrate, ultrasonically clean the SOI in acetone, ethanol, and deionized water for 5 minutes, dry it with nitrogen, and bake it on a hot plate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com