Layer-by-layer self-assembly pH response type silicon dioxide nano-container and preparation thereof, and application of silicon dioxide nano-container in composite silane film

A layer-by-layer self-assembly and silicon dioxide technology, which is applied in the direction of anti-corrosion coatings, etc., can solve the problems of cumbersome and complicated operation steps and the influence of coating stability, and achieve the effect of simple coating structure design, low cost, and inhibition of corrosion expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A method for preparing layer-by-layer self-assembled pH-responsive silica nano-containers, comprising the following steps:

[0054] (1) Synthesize silica nano-containers (that is, hollow mesoporous silica nanoparticles) by the dura plate method, and obtain well-dispersed silica microspheres by a method with simple process and low cost.

[0055] The specific process is: Stir and mix 55mL deionized water, 0.16g CTAB, 26mL ethanol and 1mL TEOS for 5min, then add 1mL ammonia water, stir at room temperature for 3h, collect the solid phase by centrifugation, wash repeatedly with deionized water and ethanol, and dry , calcined at 550°C for 5h to remove the dura mater and obtain hollow mesoporous silica nanoparticles.

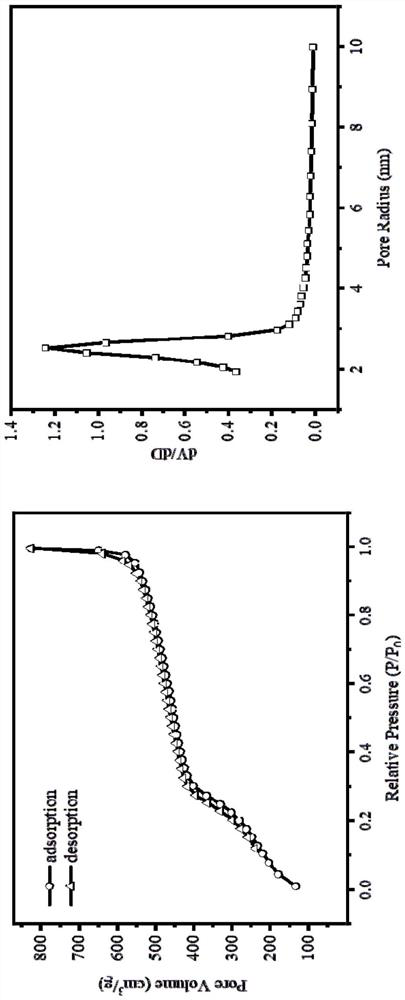

[0056] like figure 1 As shown, it is the nitrogen adsorption-desorption diagram and pore size distribution diagram of hollow silica nanoparticles, and the specific surface area is 1275.5403m 2 / g, the pore volume is 1.2765ml / g, the average pore diameter measur...

Embodiment 2

[0063] With SiO prepared by the above-mentioned embodiment 1 2 Layer-by-layer self-assembly of pH-responsive silica nanocontainers with / PEI / PSS / PEI / PSS structure for the preparation of composite silane membranes

[0064] Soak the metal substrate working electrode in the composite silane solution containing mesoporous silica nanoparticles loaded with corrosion inhibitor. After 5 minutes, take out the working electrode and dry it for curing. The drying temperature is 80°C and the drying time is 2 hours. A composite silane film attached to the working electrode was obtained. The metal substrate here is aluminum alloy.

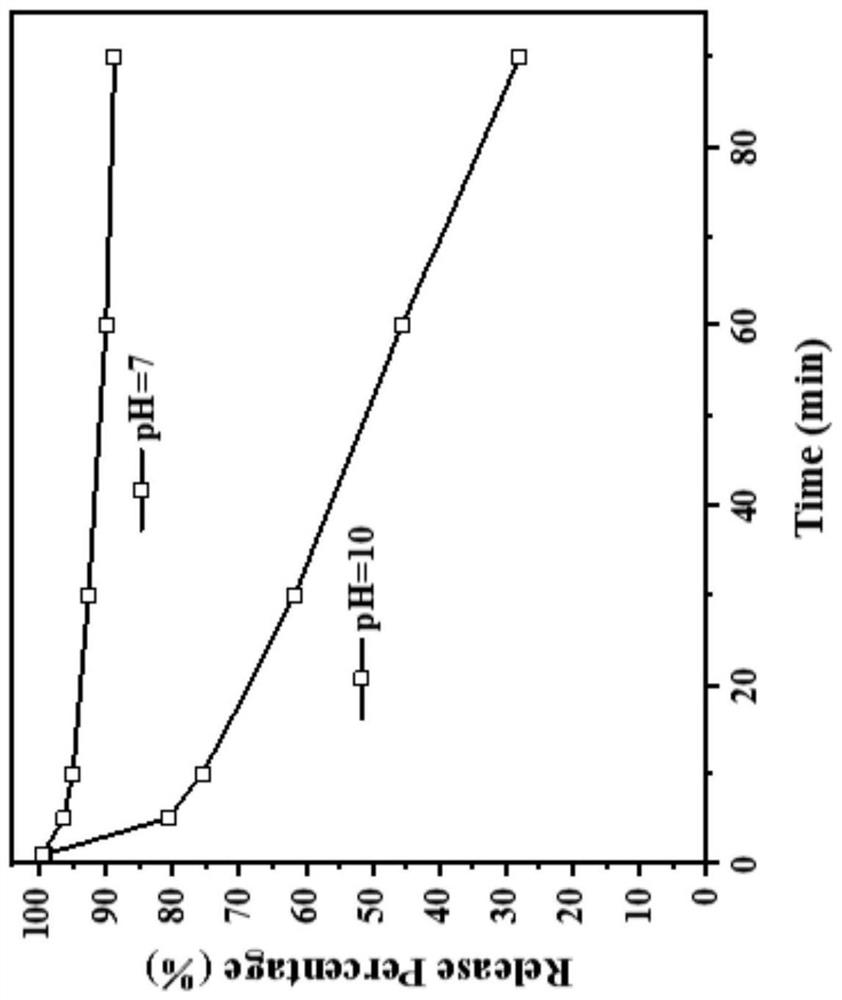

[0065] The three-electrode system (the three-electrode system uses platinum wire as the counter electrode, calomel as the reference electrode, and the metal substrate attached to the composite silane film as the working electrode) is immersed in 3.5wt% sodium chloride solution, and the The data measured by the ChemStation prove that the composite silane film of...

Embodiment 3

[0080] Compared with Example 1, most of them are the same, except that the preparation process of hollow mesoporous silica nanoparticles in this example is as follows:

[0081] Stir and mix 50mL of deionized water, 0.10g of CTAB, 20mL of ethanol and 0.5mL of TEOS for 3min, then add 1mL of ammonia water, stir at room temperature for 2h, collect the solid phase by centrifugation, wash repeatedly with deionized water and ethanol, and dry it at 530 Calcining at ℃ for 3 hours to remove the dura mater to obtain hollow mesoporous silica nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com