High-barrier degradable film and preparation method thereof

A degradable film, high barrier technology, applied in coatings, cellulose coatings, etc., can solve the problems of low barrier properties, poor heat resistance, poor mechanical properties of high barrier films, etc., to achieve low cost, excellent barrier properties, and application range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Modified hexagonal boron nitride is made by the following steps:

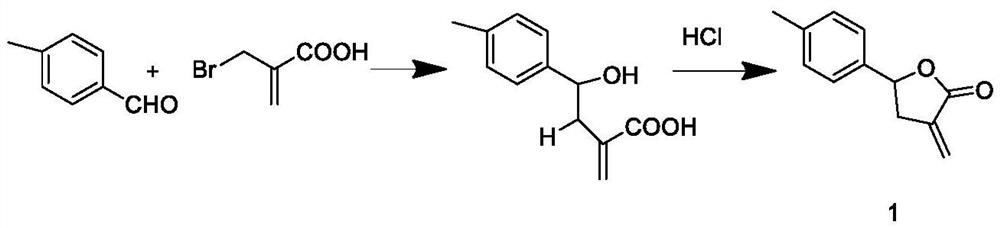

[0050] Step S11, add 1mmol of p-tolualdehyde, 1.0mmol of 2-(bromomethyl)acrylic acid, 5mL of THF and 5mL of deionized water into a round bottom flask, stir for 3min, add 1.1mmol of indium powder, magnetically stir, and track by TLC. After the raw material point of aldehyde disappears, add hydrochloric acid solution and stir for 3 hours, extract with ethyl acetate, dry with anhydrous sodium sulfate, filter, and rotary evaporate under reduced pressure to obtain intermediate 1;

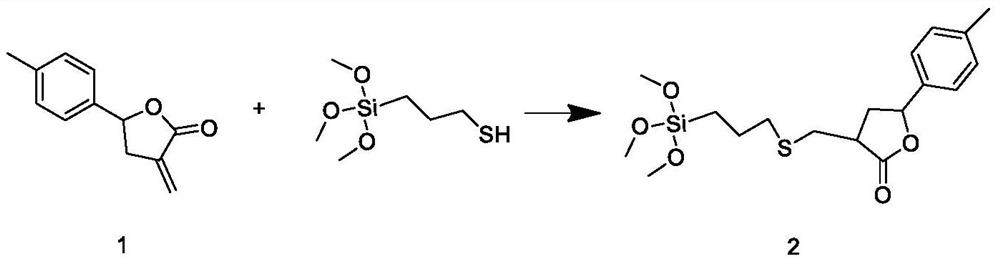

[0051] Step S12: Add 0.1 mol of intermediate 1, 0.1 mol of coupling agent KH-590 and 68 mL of toluene solvent into the three-necked flask, stir at a speed of 60 r / min for 5 min, inject nitrogen gas, raise the temperature to 40 ° C, and add 2 mL of triethylamine, Reflux reaction for 50min to obtain intermediate 2;

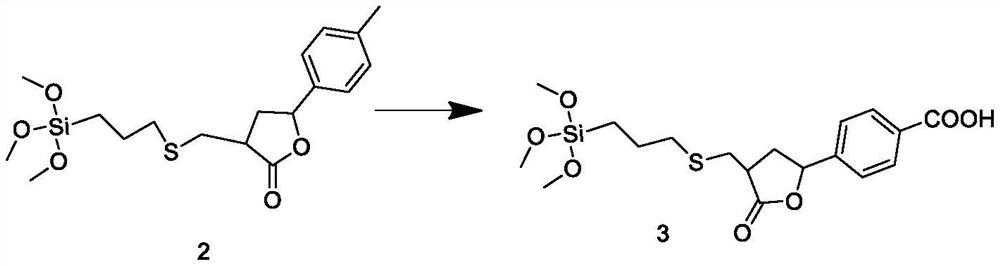

[0052] Step S13, add 2.1g of intermediate 2 and 25mL of DMF into the reaction kettle, add 0.3g of potassium permangan...

Embodiment 2

[0056] Modified hexagonal boron nitride is made by the following steps:

[0057] Step S11, add 1mmol of p-tolualdehyde, 1.2mmol of 2-(bromomethyl)acrylic acid, 5mL of THF and 8mL of deionized water into a round bottom flask, stir for 3min, then add 1.1mmol of indium powder, magnetically stir, and track by TLC. After the raw material point of aldehyde disappears, add hydrochloric acid solution and stir for 6 hours, extract with ethyl acetate, dry with anhydrous sodium sulfate, filter, and rotary evaporate under reduced pressure to obtain intermediate 1;

[0058] Step S12: Add 0.1 mol of intermediate 1, 0.1 mol of coupling agent KH-590 and 72 mL of toluene solvent into the three-necked flask, stir at 80 r / min for 5 min, inject nitrogen gas, raise the temperature to 40 °C, add 4 mL of triethylamine, Reflux reaction for 50min to obtain intermediate 2;

[0059] Step S13, add 2.4g of intermediate 2 and 28mL of DMF into the reaction kettle, add 0.3g of potassium permanganate and 6mL...

Embodiment 3

[0063] Modified nanocellulose is made by the following steps:

[0064] Step S21, add 2.1g nanocellulose and 25mL deionized water into a three-necked flask, stir for 3min, then add 1.5mL acidic NaIO 4 The solution was placed in a dark place at 40°C and stirred for 4 hours. After the reaction was completed, it was dialyzed for 2 days and dried by centrifugation to obtain intermediate a;

[0065] Step S22: Add 2.5 g of 3,5-bis(tert-butyl)-4-hydroxyphenylpropionyl chloride and 5 mL of acetonitrile into the reaction kettle, add 2 mL of hydrazine hydrate dropwise after stirring for 5 min, stir in an ice bath for 15 min, and filter , the filter cake was washed with ethanol for 3 times, and dried to constant weight at 45°C to obtain intermediate b; 50 mmol of intermediate b and 42.4 mL of DMF were added to a three-necked flask, and 5 mL of a DMF solution of intermediate a was added dropwise to the three-necked flask , stirred and reacted at 80° C. for 3 hours, after the reaction was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com