Foamy copper loaded nickel-molybdenum-phosphorus-based composite material and preparation method and application thereof

A composite material and foamed copper technology, which is applied in the field of foamed copper-supported nickel-molybdenum-phosphorus-based composite materials and its preparation, to achieve the effects of accelerating material transfer, enhancing hydrogen evolution reaction activity, and reducing charge transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] Embodiment of the present invention provides a method for preparing a foamed nickel, molybdenum and phosphorus supported copper-based composite material, comprising the steps of:

[0033] Sl, take ammonium persulfate and potassium hydroxide, deionized water was added to the mixture arranged A, the pretreated copper foam mixture placed in A, the reaction was allowed to stand, to give Cu (OH) 2 / CF;

[0034] S2, take nickel nitrate hexahydrate Ni (NO 3 ) 2 · 6h 2 O, sodium molybdate dihydrate H 4 MoNa 2 O 6 And urea, deionized water was added to a mixture of configured B, and Cu (OH) 2 / CF B placed in the liquid mixture, a hydrothermal reaction in an autoclave, to give NiMoL DH @ Cu (OH) 2 Nanoarray, washed with water, to give after lyophilization NiMo LDH @ Cu (OH) 2 / CF nanocomposite;

[0035] S3, the NiMo LDH @ Cu (OH) 2 / Nanocomposite phosphide raw material is mixed with CF2, disposed after firing, cooling tube furnace to give a copper loading of foam nickel, molybden...

Embodiment 1

[0050] This embodiment provides a method for preparing a foam-copper load nickel molybdenum phosphorus compound, including the steps of:

[0051] S1, take the foam copper to cut into 1 × 3 cm 2 Shape number, put it in anhydrous ethanol, 15min, then use 1 mol L -1 Hydrochloric acid is solened to clean the oxide of the surface of the foam, and finally use deionized water for 10 min. Then, 0.41 g of ammonium sulfate and 2.53 g of potassium hydroxide in two beakers, respectively, 7.5 ml of deionized water forming solution, then mixed, ultrasonic 5min, configured to clear the solution; copper after pretreatment In the mixed solution, stand for 20 min, then rinsed with deionized water several times, the color of the foam copper be bright blue, that is, Cu (OH) 2 / Cf.

[0052] S2, 1 mmol hexahydrate nickel nickel, 1 mmol dihydration sodium molybdate and 5 mmol urea in a 50 ml tapered bottle, add 30 mL of deionized water, ultrasonic 10min to form a uniform and transparent light green sol...

Embodiment 2

[0058] This embodiment provides a method of preparing a foam-loaded nickel-molybdenum phosphorus-based composite, and the difference from Example 1 is:

[0059] In step S2, it is 2 h at 180 ° C for 2 h to obtain NIMOL DH @ Cu (OH) 2 Nanometer array;

[0060] Other steps and parameters are the same as in Example 1.

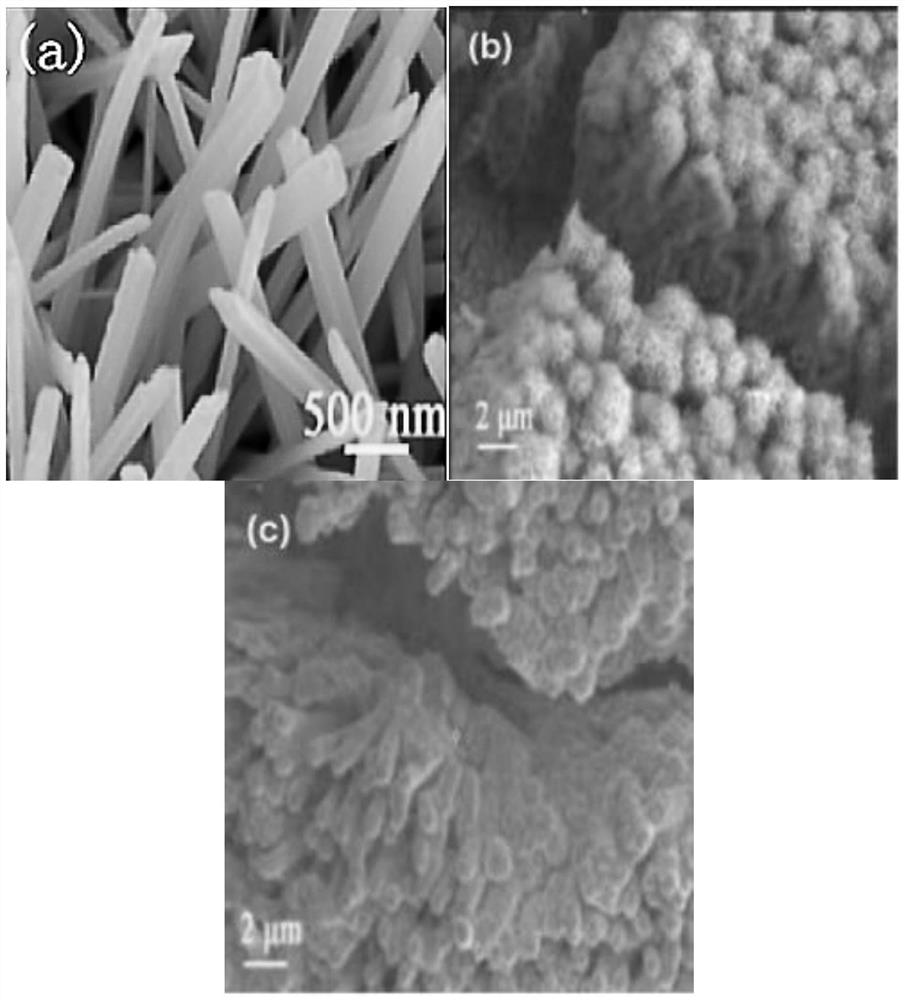

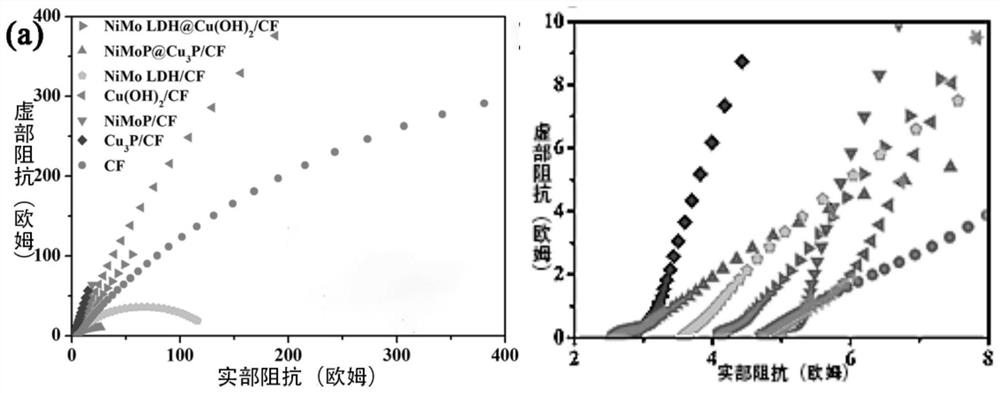

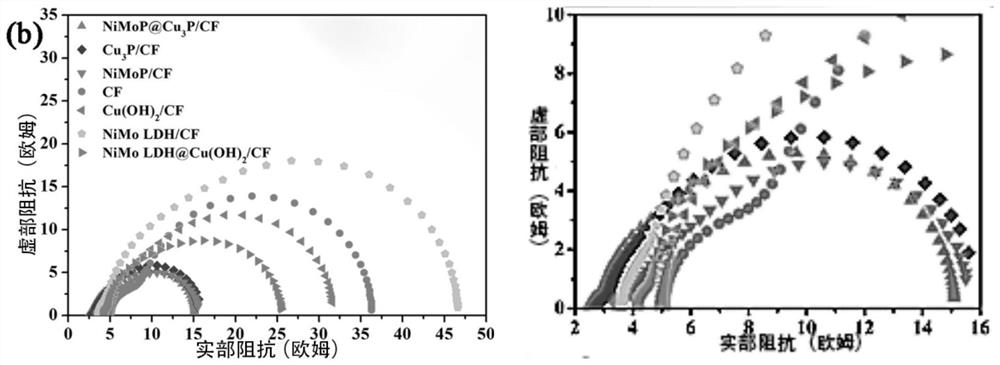

[0061] 2 is CF, Cu (OH) of Example 2 2 / Cf, cu 3 P / CF, NIMO LDH / CF, NIMOP / CF, NIMO LDH @ Cu (OH) 2 / Cf and nimop @ cu 3 P / CF impedance map, where Figure 2 (a) is CF, Cu (OH) 2 / Cf, cu 3 P / CF, NIMO LDH / CF, NIMOP / CF, NIMO LDH @ Cu (OH) 2 / Cf and nimop @ cu 3 P / CF's Energy Templer, which is tested under the open circuit voltage and the external voltage (-0.2V Versus Rhe). As can be seen from the figure, for all synthetic materials, their solution resistors (RS) are small (3 P / CF's RS minimum (2.5Ω), which indicates the nimop @ CU of the rod structure 3 The P and CF substrates have good contact to reduce the resistance.

[0062] As shown in Figure 2 (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com