Double-layer carbon-coated cobalt-based/cobalt-based chalcogenide composite electrode material, and preparation method and application thereof

A carbon-coated cobalt-based, composite electrode technology, applied in the preparation/purification of carbon, battery electrodes, carbon compounds, etc., can solve the problems of incomplete structure and volume change, achieve low cost, alleviate volume expansion, maintain The effect of structural integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

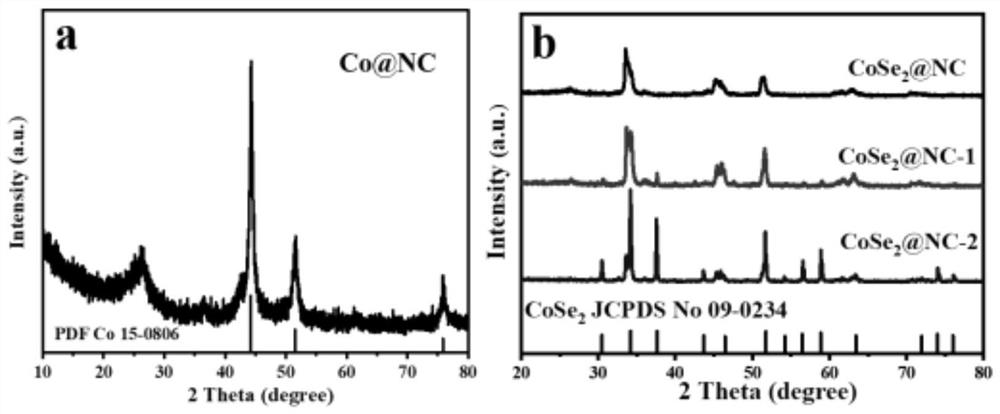

[0035] Preparation of Co@NC Composite Electrode Material

[0036] Dissolve 0.9g cobalt nitrate hexahydrate and 0.9g zinc nitrate hexahydrate in 12mL deionized water and stir for 30 minutes; dissolve 5.5g 2-methylimidazole in 20mL aqueous solution and stir for 30 minutes, then 2-methylimidazole The solution was added to the above solution, stirred for 6 hours, the blue precipitate was collected by separation, washed with ethanol, and dried overnight at 120°C to obtain Co-Zn-ZIFs; then 0.8g Co-Zn-ZIFs and 0.8g melamine were dissolved in 40mL ethanol and stirred 0.5h, collected by centrifugation. 0.8g Co-Zn-ZIFs / melamine was heated up to 800°C and kept for 2 hours to prepare Co@NC, wherein the heating rate was 3°C / min.

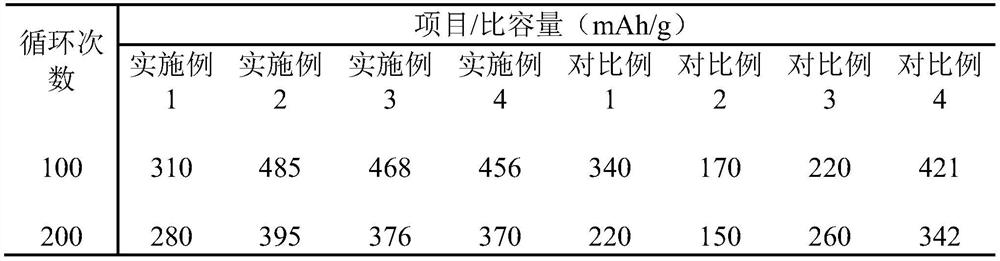

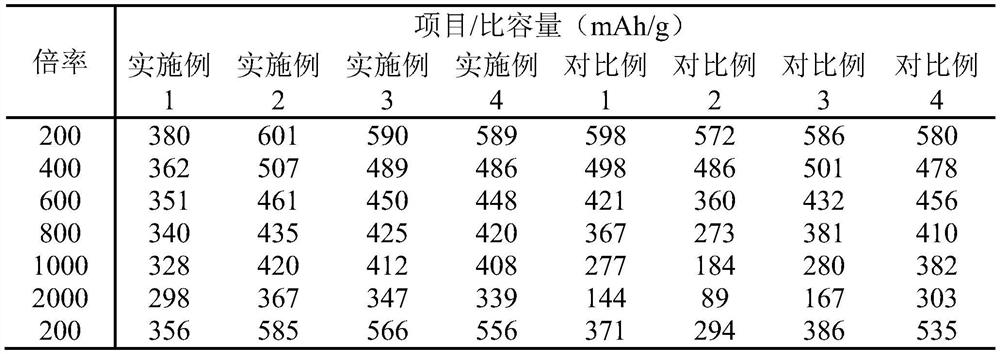

[0037] During the preparation of Co@NC composite electrode materials, the mass ratio of cobalt salt and zinc salt was continuously adjusted, and four ratio experiments of 0.8:1, 1:1, 1:5, and 1:2 were carried out. Under the current density of 0.5A / g, the cycl...

Embodiment 2

[0039] CoSe 2 Preparation of @NC composite electrode materials

[0040] During the experiment, the effect of different mass ratios of the inorganic-organic hybrid precursor and the melamine on the performance of the composite electrode material obtained later was also studied. Under the condition that other experimental parameters were the same, the experiments were carried out respectively. 0.6:1, 1:1, 2:1, 3:1 four ratio comparison experiments, when the melamine content is less, the carbon content decreases, the carbon coating effect is not good, when the melamine content increases, the carbon content increases High, the capacity of the composite electrode material will decrease again, the relative preferred ratio is 1:1.

[0041] Dissolve 0.9g cobalt nitrate hexahydrate and 0.9g zinc nitrate hexahydrate in 12mL deionized water and stir for 30 minutes; dissolve 5.5g 2-methylimidazole in 20mL aqueous solution and stir for 30 minutes, then 2-methylimidazole The solution wa...

Embodiment 3

[0043] Dissolve 0.9g cobalt nitrate hexahydrate and 1.35g zinc nitrate hexahydrate in 12mL deionized water and stir for 30 minutes; dissolve 5.5g 2-methylimidazole in 20mL aqueous solution and stir for 30 minutes, then 2-methylimidazole The solution was added to the above solution, stirred for 6 hours, the blue precipitate was collected by separation, washed with ethanol, and dried overnight at 120°C to obtain Co-Zn-ZIFs; then 0.8g Co-Zn-ZIFs and 0.8g melamine were dissolved in 40mL ethanol and stirred 0.5h, collected by centrifugation. 0.8g Co-Zn-ZIFs / melamine was heated up to 800°C and kept for 2 hours to prepare Co@NC, wherein the heating rate was 3°C / min. Mix 0.1g Co@NC with selenium powder and anneal at 600°C for 2 hours to obtain CoSe 2 @NC Composites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com