Selenium antimony sulfide thin film solar cell with 3D structure and preparation method thereof

A thin-film solar cell and antimony sulfide technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low conversion efficiency of thin-film solar cells and serious interface recombination, so as to improve cell conversion efficiency, reduce interface recombination, and improve photoelectricity. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

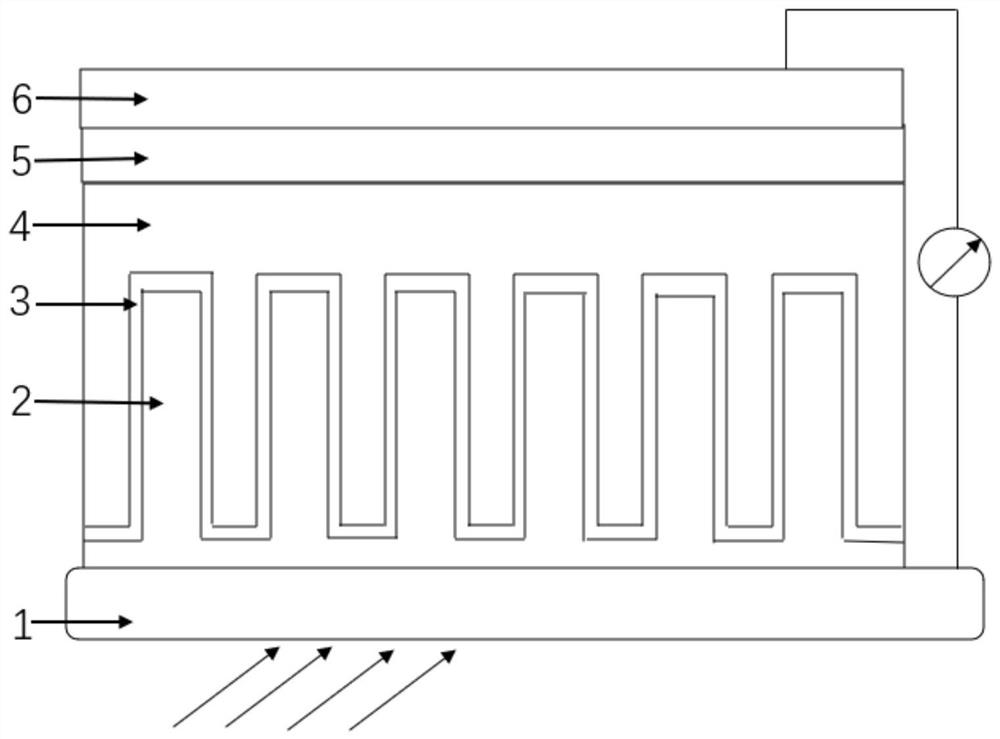

[0037] The present application also provides a preparation method of a selenium sulfide antimony thin film solar cell with a 3D structure in order to prepare the above Sb with a 3D structure 2 (S, Se) 3 A thin film solar cell comprising the steps of:

[0038] S1. Substrate cleaning: using the substrate glass as the window layer, cleaning the substrate glass;

[0039] S2. Preparation of buffer layer: Precursor solution A is obtained by configuring titanium-containing compound and organic alcohol solution, and the precursor solution A is spin-coated on the substrate glass described in step S1, dried and annealed to obtain TiO 2 seed layer film;

[0040] Dilute the titanium-containing compound with ultra-pure water and mix it evenly, configure it in an acidic environment to obtain a precursor solution B, add a template agent or ammonium fluorotitanate to the precursor solution B, and place the TiO 2 Preparation of 3D-TiO by Hydrothermal Synthesis of Seed Layer Thin Films 2 ar...

Embodiment 1

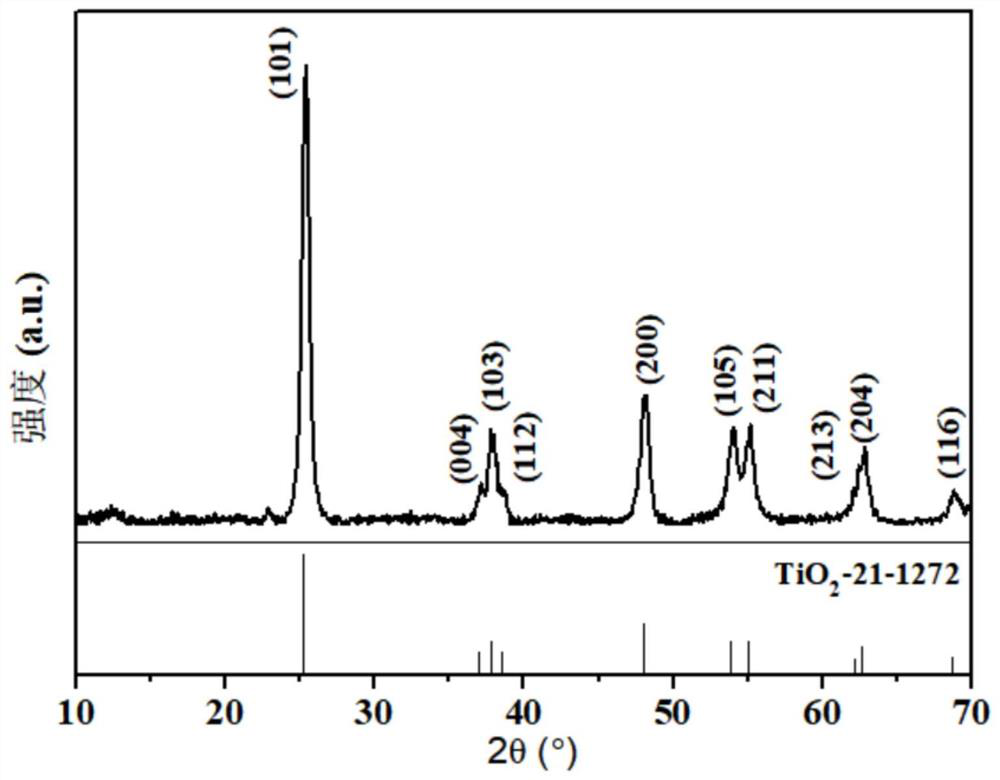

[0056] S1. Take 1ml of tetrabutyl titanate and 20ml of ethanol solution, stir for 0.5h to obtain precursor solution A, spin-coat on the surface of FTO glass at a speed of 1500rpm, pre-anneal on a heating platform at 100°C for 3min, Spin-coat 10 layers and heat-treat TiO in a muffle furnace at 200 °C for 60 min 2 seed layer film;

[0057] S2. Weigh 0.5ml of tetrabutyl titanate into 25ml of ultrapure water, adjust the pH to 0.5 with concentrated hydrochloric acid, stir for 10min, then add 0.5g of ammonium fluorotitanate, and obtain precursor solution B after the solution is clarified. Transfer the precursor solution B to a Teflon tank, put TiO 2 The seed layer film was heated at 180°C for 16h and then heat-treated at 550°C for 60min to obtain TiO 2 array;

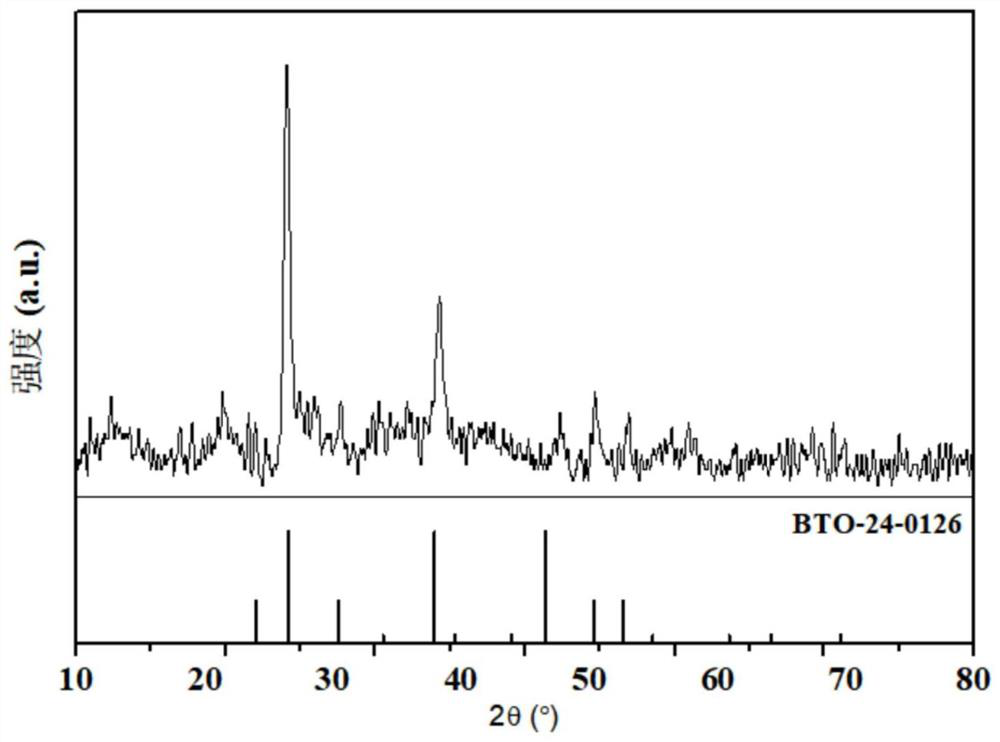

[0058] S3. Weigh 0.05mmol of barium hydroxide in 30ml of ethanol, diethylene glycol, and propanol mixed solution, adjust the pH of the system to 9 with NaOH to regulate BaTiO 3 Morphology, obtain the precursor solution C,...

Embodiment 1

[0061] Comparative experiment 1 of embodiment 1

[0062] S1. Take 1ml of tetrabutyl titanate and 20ml of ethanol solution, stir for 0.5h to obtain precursor solution A, spin-coat on the surface of FTO glass at a speed of 1500rpm, pre-anneal on a heating platform at 100°C for 3min, Spin-coat 10 layers and heat-treat TiO in a muffle furnace at 200 for 60 min 2 seed layer film;

[0063] S2. Weigh 0.5ml of titanium-containing compound in 25ml of ultrapure water, adjust the pH to 0.5 with concentrated hydrochloric acid, stir for 10min, then add 0.5g of ammonium fluorotitanate, and obtain precursor solution B after the solution is clarified. Bulk solution B was transferred to a polytetrafluoroethylene tank and put in TiO 2 Seed layer film, heated at 180°C for 16h, then heat-treated at 550°C for 60min to TiO 2 array;

[0064]S3. Weigh 1mmol of tartaric acid, 9mmol of thiourea, and 2mmol of antimony chloride and dissolve them in 100ml of ultrapure water to obtain precursor solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com