HEMT device based on sputtering AlON/diamond substrate and preparation method thereof

A diamond and device technology, which is applied in the field of HEMT devices and its preparation, can solve the problems of difficult MOCVD direct epitaxy, poor thermal stability, and large gaps, so as to facilitate large-scale integration, improve device quality, and improve device performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

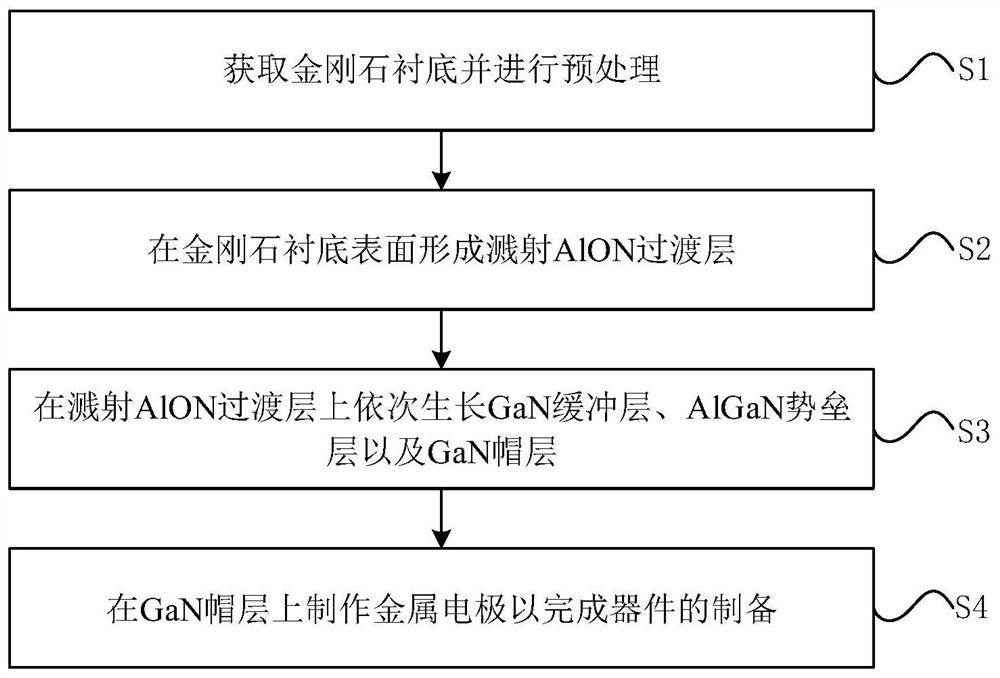

[0042] See figure 1 , figure 1 It is a schematic flowchart of a method for preparing a HEMT device based on sputtering AlON / diamond substrate provided by the embodiment of the present invention, including:

[0043] S1: Obtain a diamond substrate and perform pretreatment.

[0044] Specifically, a diamond substrate with a certain crystal orientation is selected, placed in an acetone solution, an anhydrous ethanol solution and deionized water for ultrasonic cleaning for 2-10 min each, and then dried with nitrogen.

[0045] In this embodiment, a diamond substrate is selected as the bottom plate of the device, because the high thermal conductivity of the diamond substrate can greatly improve the heat dissipation capability of the device, which is beneficial to large-scale integration.

[0046] S2: A sputtered AlON transition layer is formed on the surface of the diamond substrate.

[0047] Because the difference between the diamond material and the GaN material is too large, it ...

Embodiment 2

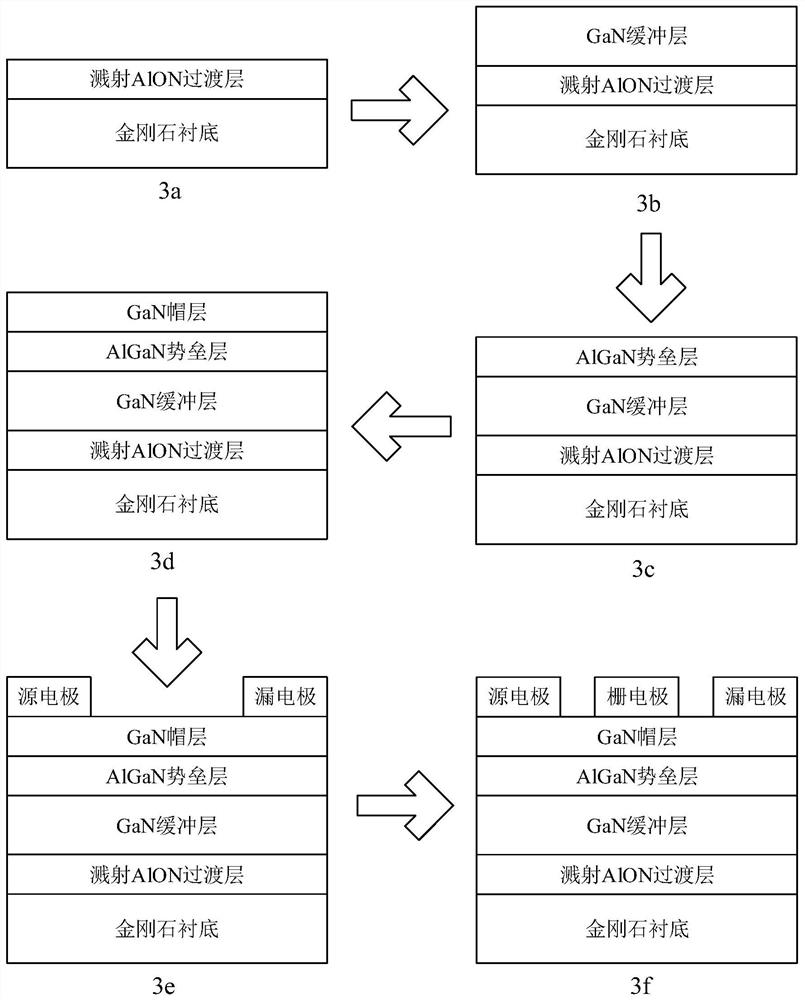

[0068] On the basis of the above-mentioned first embodiment, this embodiment provides a HEMT device based on sputtered AlON / diamond substrate. See figure 2 , figure 2 It is a schematic diagram of a HEMT device structure based on sputtered AlON / diamond substrate provided by the embodiment of the present invention. The device structure includes from bottom to top: a diamond substrate, a sputtered AlON transition layer, a GaN buffer layer, an AlGaN barrier layer, GaN cap layer, source-drain electrodes, and gate electrodes. The thickness of the AlON transition layer is 10-100 nm, the thickness of the GaN buffer layer is 1-3 μm, the thickness of the AlGaN barrier layer is 20-60 nm, and the thickness of the GaN cap layer is 2-6 nm.

[0069] The HEMT device based on the sputtered AlON / diamond substrate provided in this embodiment can be prepared by the preparation method provided in the above-mentioned Embodiment 1, and the specific preparation process is not repeated here.

Embodiment 3

[0071] Hereinafter, the preparation method provided in the above Embodiment 1 will be described in detail by taking the preparation of a GaN-based HEMT device with an AlON transition layer thickness of 10 nm as an example.

[0072] See image 3 a-3f, image 3 a-3f is a schematic diagram of the preparation process of the HEMT device based on the sputtered AlON / diamond substrate provided in the embodiment of the present invention. details as follows:

[0073] Step 1: Process the diamond substrate.

[0074] The diamond substrate was placed in acetone solution, absolute ethanol solution and deionized water for ultrasonic cleaning for 2 min each, and then dried with nitrogen.

[0075] Step 2: Sputtering the AlON transition layer.

[0076] The treated diamond substrate is put into a magnetron sputtering furnace for growth, the air pressure is 50 Torr, the sputtering power is 1000W, the flow rate of oxygen gas is 2sccm, the flow rate of argon gas is 50sccm, and the flow rate of n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com