Method for treating fluorine-containing wastewater of photovoltaic enterprise

A treatment method and wastewater technology, which is applied in energy wastewater treatment, water/sewage multi-stage treatment, biological water/sewage treatment, etc., can solve the problems of incomplete fluorine removal and large consumption of chemicals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

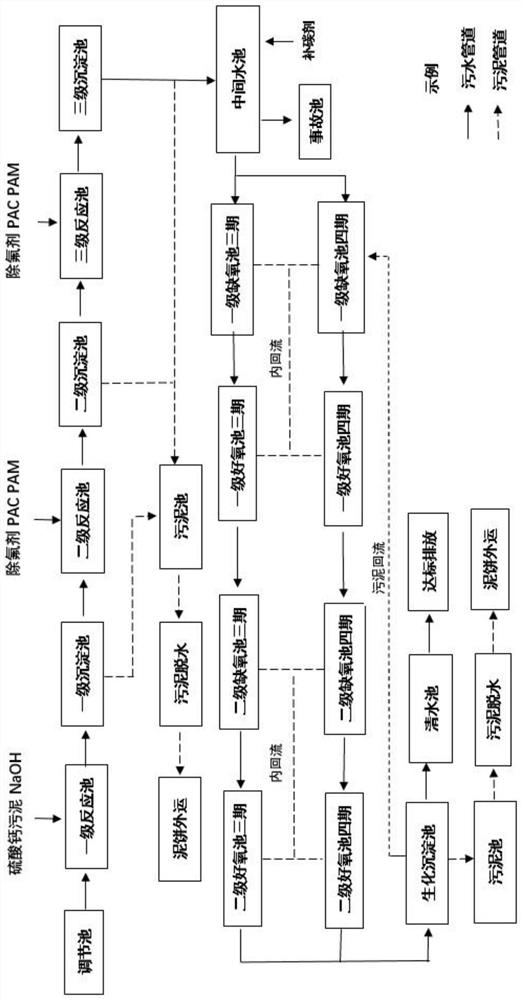

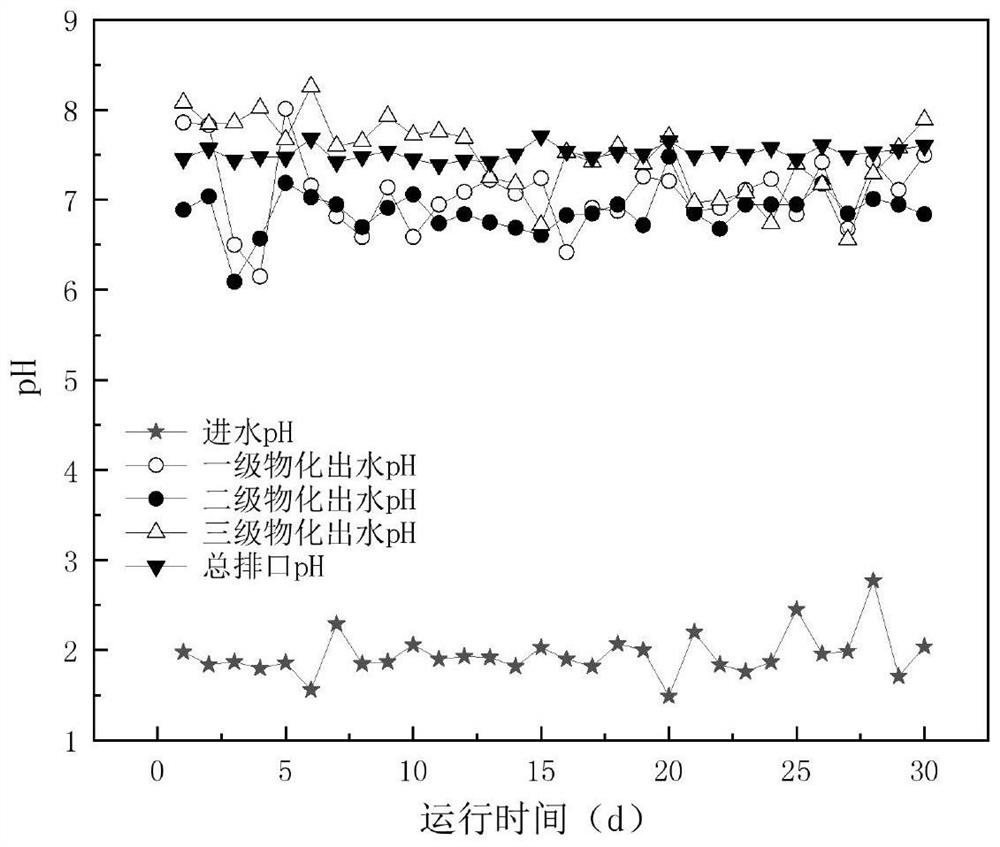

[0043]This example treats fluorine-containing wastewater located in a photovoltaic industrial park in Chengdu, and the designed daily water treatment capacity is 12,500 m 3 , for 24h continuous operation, mainly to deal with the waste water generated by the workshop's texturing, etching, SCRUBBER and other production processes and the washing water of the waste gas absorption tower. The solar crystalline silicon cell production wastewater in the photovoltaic industrial park is treated by the wastewater treatment station to meet the corresponding discharge standards, and then discharged into the municipal pipe network system. The processing steps are as follows:

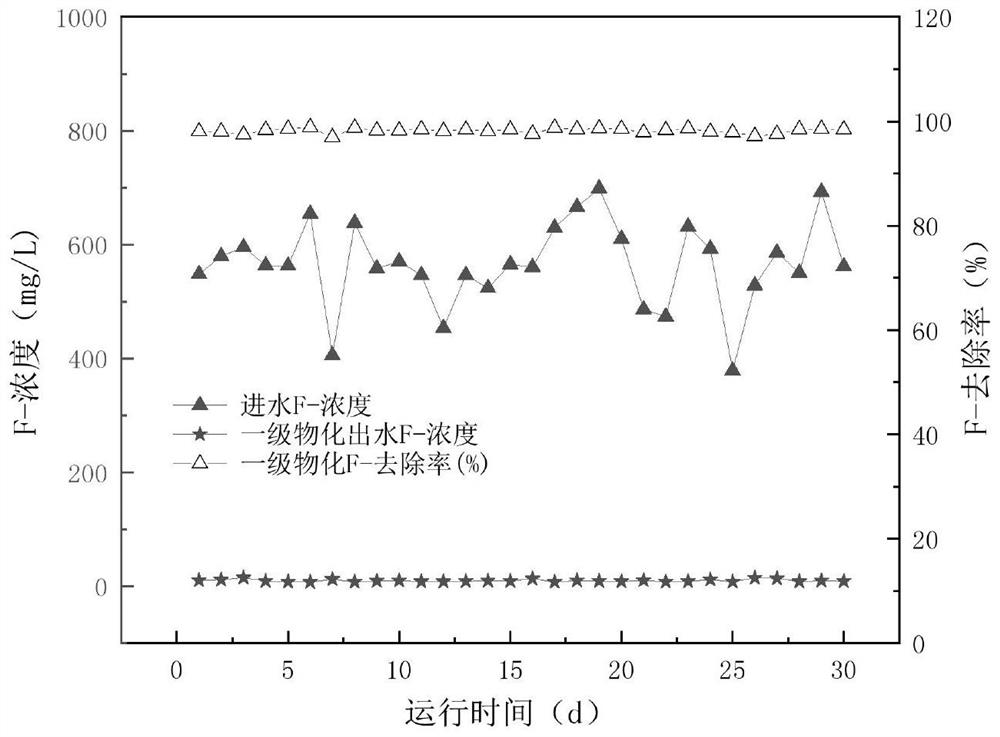

[0044] (1) Physical and chemical treatment: use the corresponding waste liquid collection tank to collect the concentrated alkali waste liquid, mixed acid waste liquid, concentrated fluorine waste water, dilute alkali waste water and dilute fluorine waste water produced in the production workshop (the treated water vo...

Embodiment 2

[0073] Source of calcium sulfate sludge:

[0074] Sulfuric acid is an important basic chemical raw material and is widely used in metallurgy, iron and steel, titanium dioxide and other fields. However, during the application process, sulfuric acid-containing wastewater will be produced, which will seriously pollute the environment and seriously endanger biological growth and human life. Therefore, it must be treated to meet the standards before it can be discharged. At present, the treatment method of waste acid at home and abroad mostly adopts the neutralization method. The medicines used are generally lime, calcium hydroxide, etc. The main principle is the SO in the waste water. 4 2- and Ca in dosing drugs + The reaction produces CaSO 4 Precipitation, so as to adjust the acidity of the wastewater, the pH of the treated wastewater needs to reach about 7 before it can be discharged. A large amount of chemicals are used in the neutralization treatment stage, so a large amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com