Colloidal silicon nanocrystal with high fluorescence quantum yield as well as preparation method and application of colloidal silicon nanocrystal

A fluorescence quantum yield, colloidal silicon technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, can solve the problems of low photoluminescence quantum efficiency, surface oxidation, etc., to improve Fluorescence quantum efficiency, complete surface modification, non-toxic effect of raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Take a 1cm×1cm single-crystal silicon wafer [thickness~350μm, p-type, (100)] that has been cleaned and dried with alcohol, deionized water, etc., put it in a sample bottle, add 15ml of toluene (>99 %) solution, put it into a magnetic stirrer, and place it on the magnetic stirrer.

[0040] (2) Pass through a titanium / sapphire laser (wavelength 800nm, pulse width 100fs, frequency 80MHz, laser energy density 0.2mJ cm) while magnetically stirring -2 ) liquid phase ablation for 60 min.

[0041] (3) The ablated sample was centrifuged at a high speed of 15,000 rpm for 3 times, and each time was 30 minutes; the upper layer solution obtained by separation was slightly turbid.

[0042] According to the above formula, the PL QY of the c-Si NCs obtained in Example 1 was 48.6%.

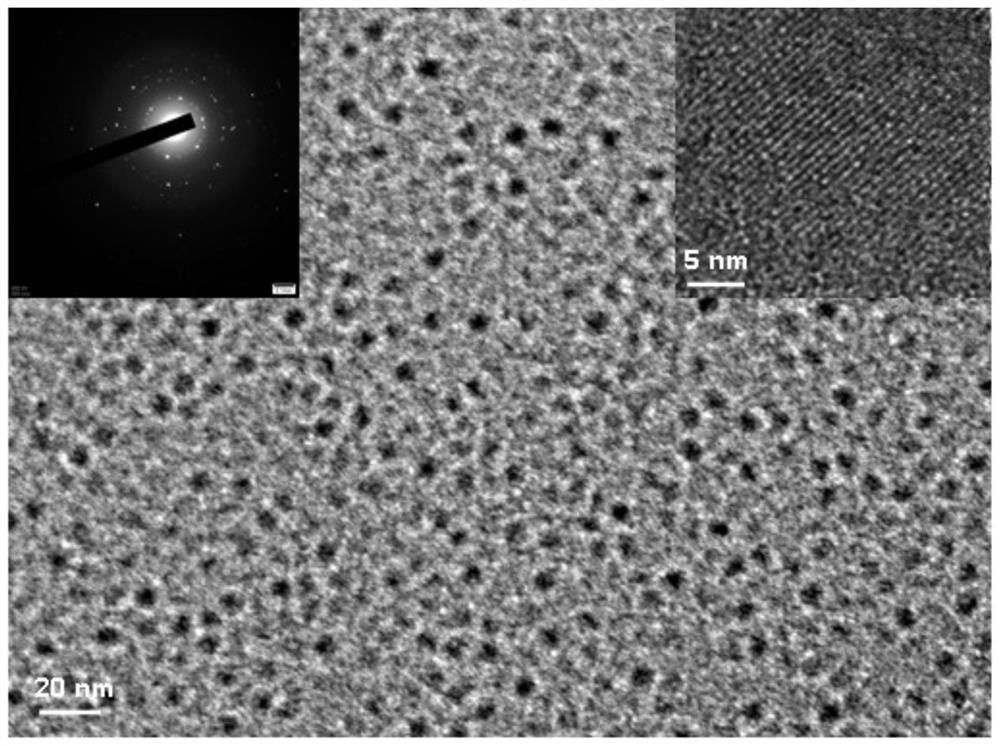

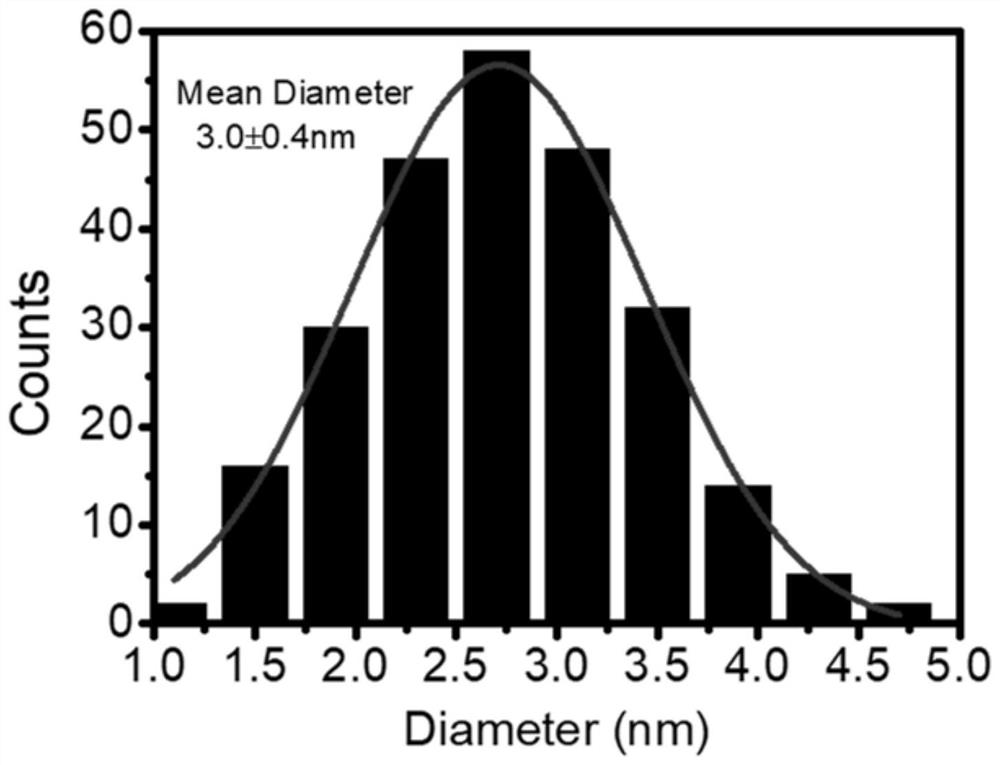

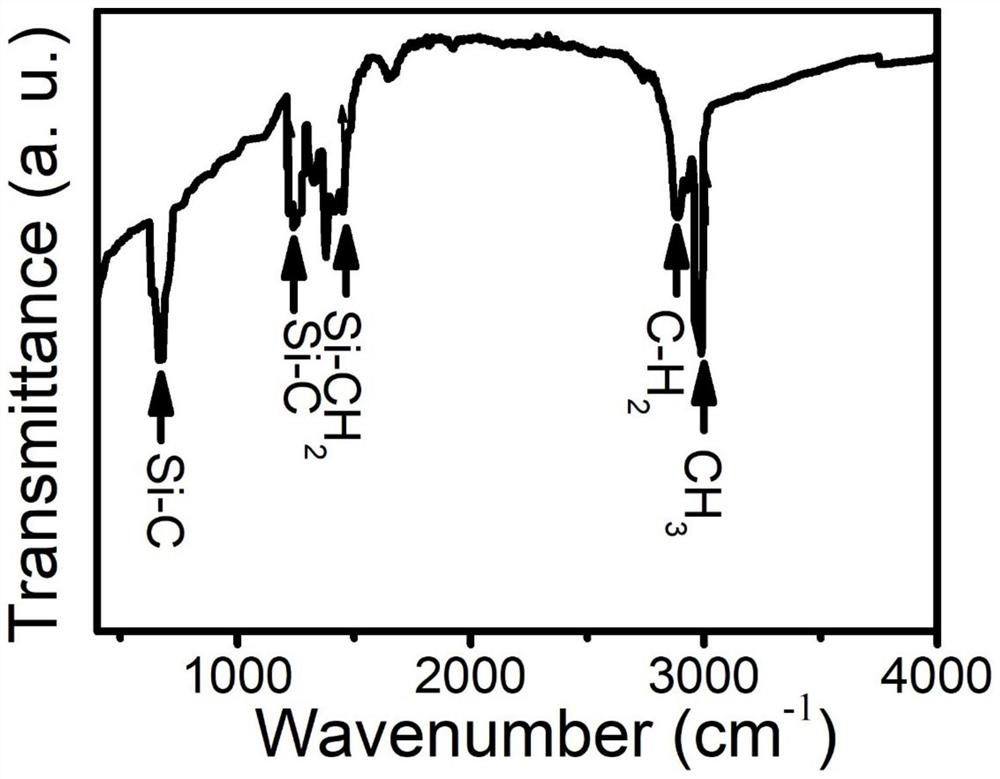

[0043]The obtained upper layer solution was characterized by structure such as XRD, XPS, FTIR, HRTEM, etc., and its optical properties such as PL, time-resolved PL, and UV-vis absorbance spectrum were...

Embodiment 2

[0045] (1) Take a 1cm×1cm monocrystalline silicon wafer same as in Example 1, put it in a sample bottle, add 15ml of mixed solvent of toluene (>99%) and HF solution, put it in a magnetic stirring bar, put it in a magnetic on the mixer. The purity of toluene used in the mixed solution is >99%; the concentration of the added HF solution is 50wt% (specific gravity 1.157), the volume percentage in the mixed solution is 5.0%, and the HF content is about 28-30g / L.

[0046] (2) Pass through a titanium / sapphire femtosecond laser (wavelength 800nm, pulse width 100fs, frequency 80MHz, laser energy density 0.2mJ cm) while magnetically stirring -2 ) liquid phase ablation for 60 min.

[0047] (3) The ablated sample was centrifuged at a high speed of 15,000 rpm for 3 times, and each time was 30 minutes; the upper layer clear liquid was obtained by separation, which was pale yellow.

[0048] The PL QY of the obtained c-Si NCs was 65.7%.

Embodiment 3

[0050] (1) Take a 1cm×1cm monocrystalline silicon wafer same as in Example 1, put it in a sample bottle, add 15ml of mixed solvent of toluene (>99%) and HF solution, put it in a magnetic stirring bar, put it in a magnetic on the mixer. The purity of toluene used in the mixed solution is more than 99%; the concentration of the added HF solution is 50wt%, the volume percentage in the mixed solution is 10.0%, and the HF content is about 57-59g / L.

[0051] (2) Pass through a titanium / sapphire femtosecond laser (wavelength 800nm, pulse width 100fs, frequency 80MHz, laser energy density 0.2mJ cm) while magnetically stirring -2 ) liquid phase ablation for 60 min.

[0052] (3) The ablated sample was centrifuged at a high speed of 15,000 rpm for 3 times, and each time was 30 minutes; the upper layer clear liquid was obtained by separation, which was pale yellow.

[0053] The PL QY of the obtained c-Si NCs was 77.2%.

[0054] figure 1 It is a transmission electron microscope image o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com