Method for preparing silicon nitride ceramic substrate through gel tape casting

A silicon nitride ceramic and gel casting technology is applied in the field of inorganic non-metals to achieve the effects of improving yield and production efficiency, good mechanical and electrical properties of products, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

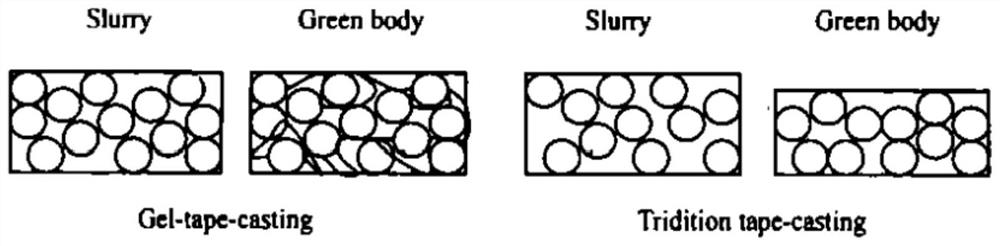

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method for gel casting molding of a silicon nitride ceramic substrate with high thermal conductivity is as follows:

[0031] (1) Weigh 1.5g of acrylamide and 0.2g of N,N'-methylenebisacrylamide, add them to 100mL of absolute ethanol, heat in a water bath at 45°C, stir for 15min, cool to room temperature and add ammonia water and hydrochloric acid to adjust the pH to be 10.4.

[0032] (2) The solution obtained in step (1), 150 g of silicon nitride powder, 1.5 g of ammonium polyacrylate, 2.5 g of yttrium oxide and 1.5 g of magnesium oxide were all added to the ball mill, and ball milled at a speed of 200 r / min for 2 hours.

[0033] (3) 6g polyethylene glycol is added to the mixture in step (2), and ball milling is continued for 8h to obtain a slurry with a certain viscosity.

[0034] (4) Add 0.4 g initiator ammonium persulfate to the slurry, vacuum defoaming for 20 min at a speed of 40 r / min, and tape casting at a temperature of 40 °C and a speed of 0.5 m / m...

Embodiment 2

[0038] (1) Weigh 1.5g of acrylamide and 0.2g of N,N'-methylenebisacrylamide, add them to 100mL of absolute ethanol, heat in a water bath at 45°C, stir for 15min, cool to room temperature and add ammonia water and hydrochloric acid to adjust the pH to be 10.4.

[0039] (2) The solution obtained in step (1), 150 g of silicon nitride powder, 1.5 g of ammonium polyacrylate, 5 g of yttrium oxide and 3 g of magnesium oxide are all added to a ball mill, and ball milled at a speed of 200 r / min for 2 hours.

[0040] (3) 8g polyethylene glycol is added to the mixture in step (2), and ball milling is continued for 8h to obtain a slurry with a certain viscosity.

[0041] (4) Add 0.4 g initiator ammonium persulfate to the slurry, vacuum defoaming for 20 min at a speed of 40 r / min, and tape casting at a temperature of 40 °C and a speed of 0.5 m / min.

[0042](5) Drying at 30° C. for 1 hour, and cutting into green sheets of predetermined size. The green sheet was first heated to 1200 °C und...

Embodiment 3

[0045] (1) Weigh 10 g of acrylamide and 1 g of N,N'-methylenebisacrylamide, add them to 100 mL of absolute ethanol, heat in a water bath at 45°C, stir for 15 min, add ammonia water and hydrochloric acid after cooling to room temperature to adjust the pH to 10.4.

[0046] (2) The solution obtained in step (1), 150 g of silicon nitride powder, 3 g of ammonium polyacrylate, 5 g of yttrium oxide and 3 g of magnesium oxide are all added to a ball mill, and ball milled at a speed of 200 r / min for 2 hours.

[0047] (3) 6g polyethylene glycol is added to the mixture in step (2), and ball milling is continued for 8h to obtain a slurry with a certain viscosity.

[0048] (4) Add 0.3 g of initiator ammonium persulfate to the slurry, vacuum defoaming at a speed of 40 r / min for 20 min, and at a temperature of 40° C., at a speed of 0.5 m / min for tape casting.

[0049] (5) Drying at 30° C. for 1 hour, and cutting into green sheets of predetermined size. The green sheet was first heated to 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com