Temperature sensing nano gel system for blood vessel embolism material

A technology of nanogel and blood vessel embolization, applied in the field of biomedical engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Preparation of thermosensitive nanogels:

[0030] According to the ratio of monomer ratio (A:B) of 80~99:1~20, weigh two kinds of comonomers, dissolve them in a certain volume of water, make the concentration of monomers 0.1~0.2mol / L, add 0.2-10% cross-linking agent based on total moles of monomers, anionic surfactant is used as emulsifier, and emulsifier concentration is 0.5-5mmo / L. The emulsifier is preferably sodium dodecyl sulfate (SDS). After passing nitrogen for 30 minutes under magnetic stirring, add a water-soluble free radical initiator, the reaction temperature is 20-90 ° C, and the reaction uses N 2 Gas protection, the reaction time is 4 ~ 24h. The nanogel dispersion obtained by the reaction is dialyzed, freeze-dried, and stored in a desiccator for future use. The concentration of the initiator used in the above process is 1-5 mmol / L, and the initiator can be potassium persulfate (KPS), ammonium persulfate-tetramethylethylenediamine or potassium persulfate...

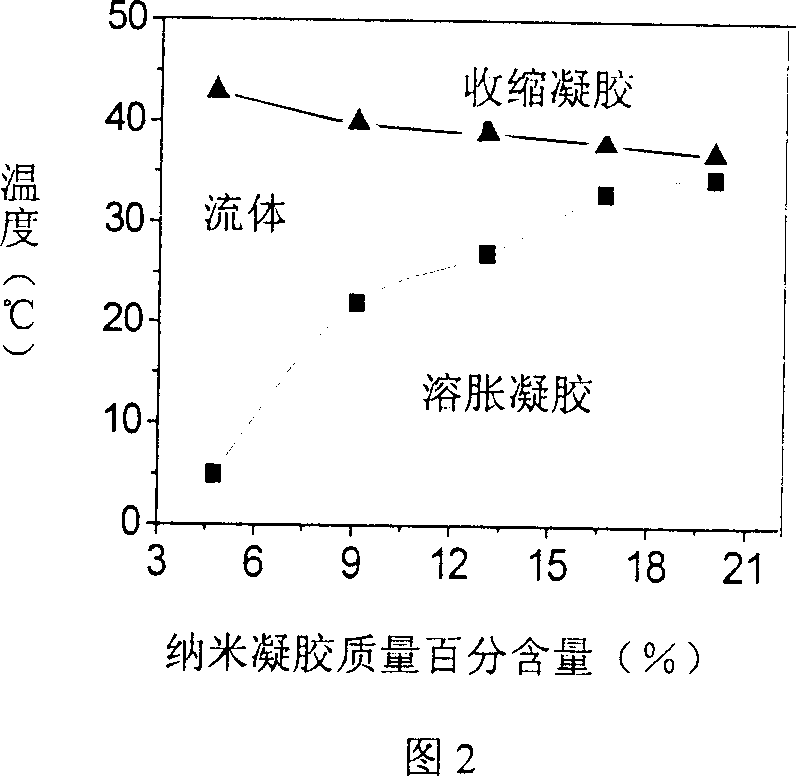

Embodiment 1

[0040] 2.263g NIPAAm (20mmol), 0.014g AAm (0.2mmol), 0.031g MBAAm (0.2mmol) and 0.030g SDS were added to a 250mL three-necked flask equipped with a reflux condenser and a gas guiding device, and a 171.3mL ultra- Pure water was dissolved under magnetic stirring. First pass high-purity nitrogen into the above reaction system for 30 minutes, then heat to 70°C, and add 0.0452g KPS to initiate the polymerization reaction. in N 2 In the atmosphere, react at 70±1°C for 4.5 hours. A white cloudy nanogel suspension was obtained. The nanogel suspension was dialyzed in ultrapure water for two weeks, 5 mL was reserved for testing, and the rest was freeze-dried to collect the freeze-dried powder.

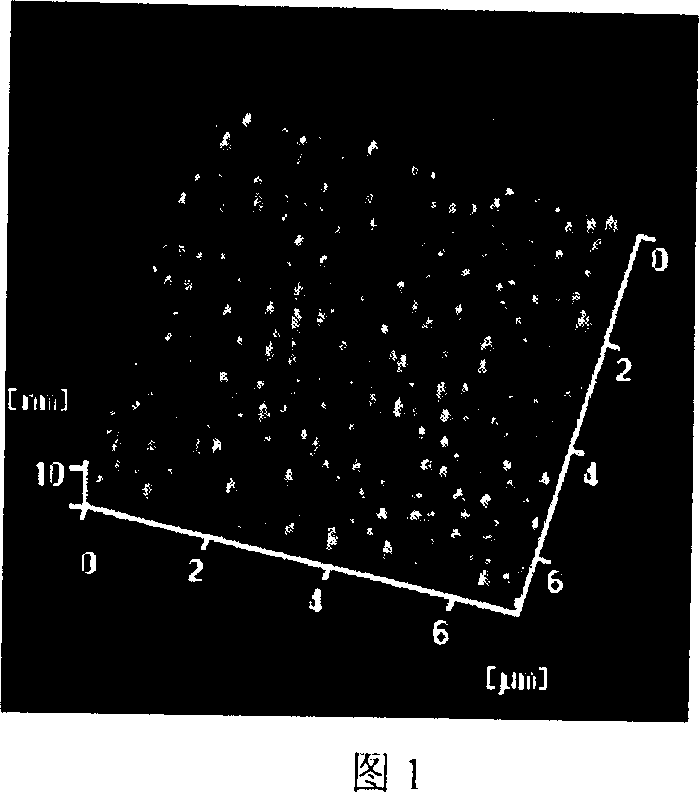

[0041] Determination of the average particle size of the nanogel particles: use a Nano-ZS 90 laser particle size analyzer (Malvern, UK) to measure, the light source is a helium-neon laser (λ=633nm), and the detection angle is 90°. The test sample is nanogel dialysate diluted with ultrapure w...

Embodiment 2

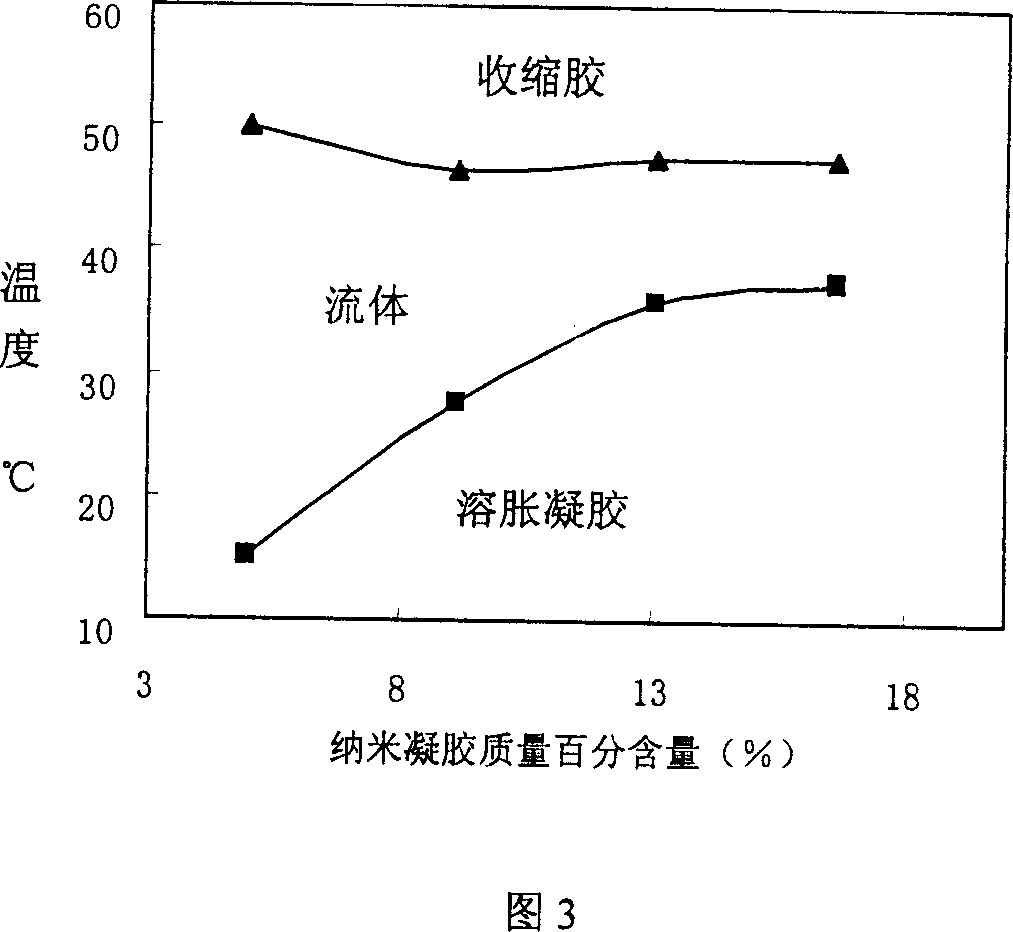

[0043] Add 1.488g NIPAAm (13mmol), 0.182g N-n-propylacrylamide (NNPAAm) (1.6mmol), 0.176g MBAAm (1.09mmol) and 0.030g SDS to a 250mL container equipped with a reflux condenser and a gas guide In a three-necked bottle, dissolve with 125mL ultrapure water under magnetic stirring. First, high-purity nitrogen was introduced into the above reaction system for 30 minutes, and then 0.050 g of ammonium persulfate and 100 μL of tetramethylethylenediamine were added to initiate the polymerization reaction. in N 2 In the atmosphere, the reaction was carried out at room temperature for 24 hours. A nanogel suspension is obtained. The nanogel suspension was dialyzed in ultrapure water for two weeks, 5 mL was reserved for testing, and the rest was freeze-dried to collect the freeze-dried powder.

[0044] Determination of the average particle size of the nanogel particles: use a Nano-ZS 90 laser particle size analyzer (Malvern, UK) to measure, the light source is a helium-neon laser (λ=633...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com