Solvent-thermal synthesis of lanthanum phosphate nanorod

A technology of lanthanum phosphate and nanorods, which is applied in the direction of phosphate, phosphorus oxyacid, etc., can solve the problems of affecting performance, powder agglomeration, poor dispersibility, etc., and achieve improved stability, enhanced application, and good dispersibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

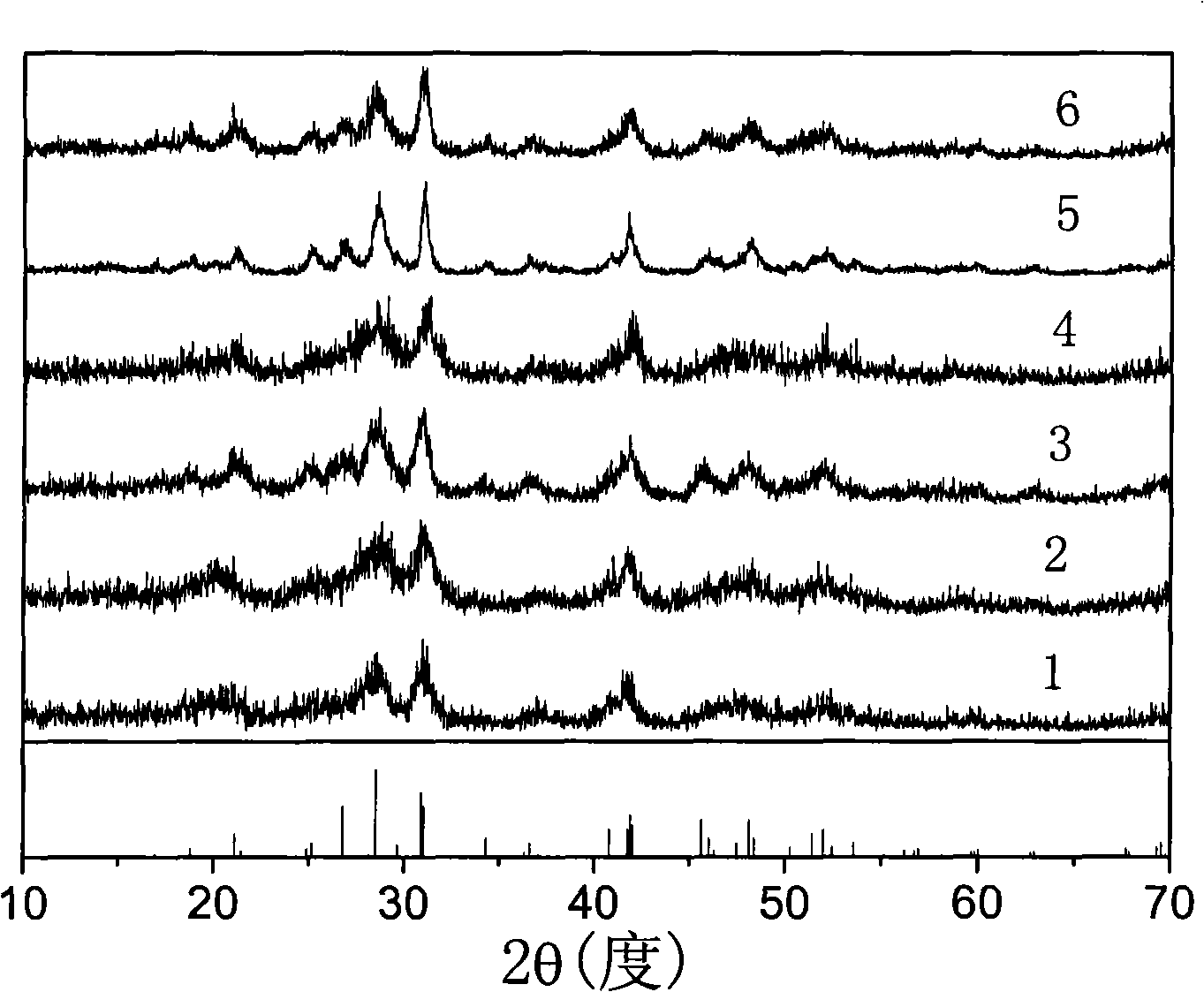

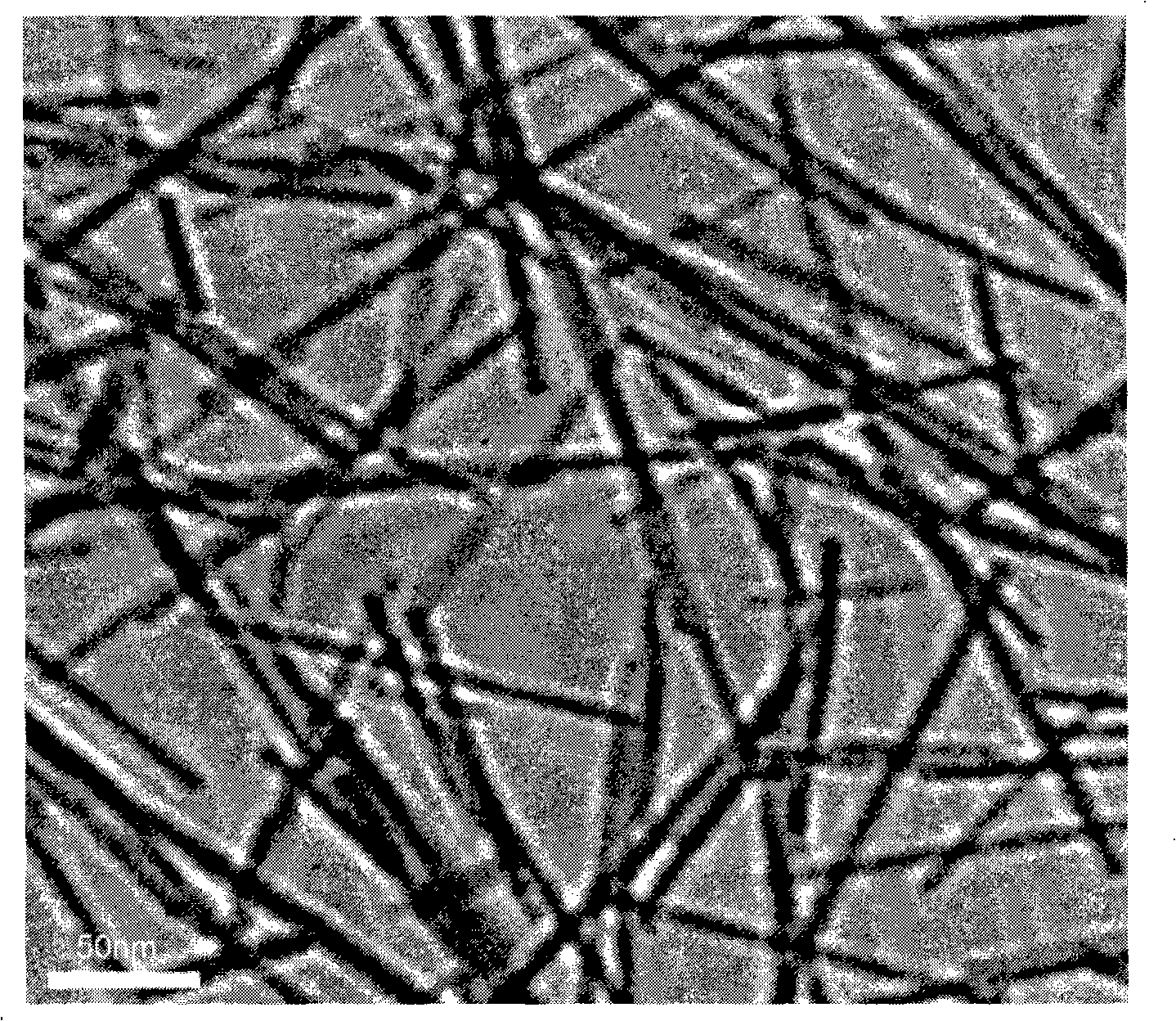

[0019] Add 10ml of 1.0mol / L lanthanum chloride aqueous solution and 10ml of 1.0mol / L sodium phosphate aqueous solution into 30ml of n-butanol, the molar concentration of lanthanum chloride in the mixed solution is 0.2mol / L, stir until evenly mixed, Phosphoric acid was used to adjust the pH of the solution to 4, transferred to a polytetrafluoroethylene-lined autoclave, and solvothermally reacted for 4 hours at 220° C. in a constant temperature box to prepare lanthanum phosphate nanorods. Such as figure 1 As shown in the middle curve 1, all diffraction peaks can correspond to the standard peaks of the monoclinic lanthanum phosphate at the bottom, thus it can be known that the obtained lanthanum phosphate nanorods are a pure-phase monazite structure, which belongs to the monoclinic system, monazite structure. According to the Scherrer formula D=κ·λ / βcosθ, κ is the Scherrer constant, generally valued at 0.89; λ is the X-ray wavelength, and the value is 0.154056nm in this embodime...

Embodiment 2

[0021] Add 1.0 mol / L lanthanum chloride aqueous solution and 1.0 mol / L sodium phosphate aqueous solution into 30 ml of n-propanol, and other experimental operations and reagent consumption are the same as those in Embodiment 1 to prepare lanthanum phosphate nanorods. Such as figure 1 As shown in middle curve 2, all diffraction peaks can correspond to the standard peaks of the monoclinic lanthanum phosphate at the bottom, thus it can be known that the obtained lanthanum phosphate nanorods are a pure-phase monazite structure. The Scherrer formula can estimate the grain size to be about 7nm.

Embodiment 3

[0023] Add 10ml of 1.5mol / L lanthanum chloride aqueous solution and 15ml of 1.0mol / L sodium phosphate aqueous solution into 25ml of n-butanol, the molar concentration of lanthanum chloride in the mixed solution is 0.3mol / L, stir until it is evenly mixed, Phosphoric acid was used to adjust the pH of the solution to 5, transferred to an autoclave lined with polytetrafluoroethylene, and subjected to solvothermal reaction at 180° C. for 24 hours in an incubator to prepare lanthanum phosphate nanorods. Such as figure 1 As shown in the middle curve 3, all diffraction peaks can correspond to the standard peaks of the monoclinic lanthanum phosphate at the bottom, thus it can be known that the obtained lanthanum phosphate nanorods are a pure-phase monazite structure. The Scherrer formula can estimate the grain size to be about 9nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com