Process for preparing high-purity raffinose from degreased cottonseed meal

A technology of degreasing cottonseed and raffinose, which is applied in the field of chemical engineering, can solve the problems of low raffinose yield, large amount of solvent, and high solution viscosity, etc., to reduce the loss of raffinose, reduce solvent consumption, and accelerate dissolution and mass transfer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

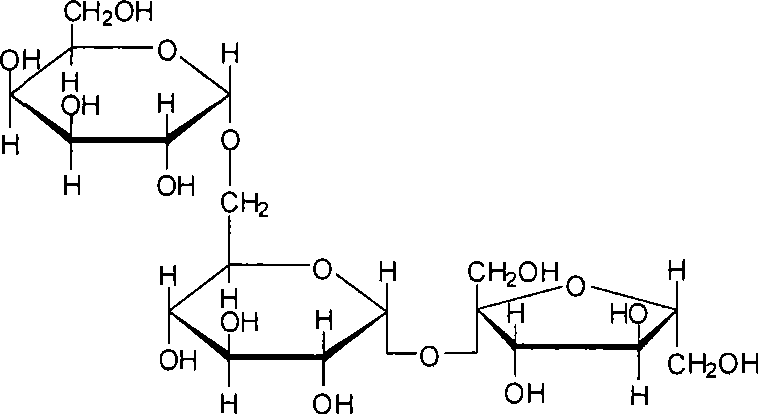

Image

Examples

Embodiment 1

[0063] (1) Degreased cottonseed meal (wherein the mass percentage of raffinose is 3.9%) is sieved through a 1.8mm sieve, weighs 435 grams and puts it into a percolation column (Φ3.5cm×70cm), and fills it evenly Its bulk volume is about 560 milliliters, then add 350 milliliters of ethanol aqueous solution with a volume percentage concentration of 75% to the percolation column, soak for 30 minutes at 55°C to fully swell the defatted cottonseed meal, open the outlet valve of the percolation column, and simultaneously The extraction solvent was continuously added to the top of the column, and the flow rate was controlled to be 168 ml / hour until the volume of the percolation extract collected was 1900 ml. After analysis, the percolation liquid has a solid content of 4.2%; on a dry basis, the mass percentage of raffinose is 38.2%.

[0064] Finally, add deionized water from the top of the percolation column to replace the residual ethanol in the defatted cottonseed meal, control the fl...

Embodiment 2

[0074] (1) Degreased cottonseed meal (wherein the mass percentage of raffinose is 3.9%) is sieved through a 1.8mm sieve, weighs 435 grams and puts it into a percolation column (Φ3.5cm×70cm), and fills it evenly The bulk volume is about 560 milliliters, then add 350 milliliters of ethanol aqueous solution with a volume percentage concentration of 85% to the percolation column, soak for 40 minutes at 70°C to fully swell the defatted cottonseed meal, open the outlet valve of the percolation column, and simultaneously The extraction solvent was continuously added to the top of the column, and the flow rate was controlled to be 450 ml / hour until the volume of the percolation extract collected was 2200 ml. The percolation liquid was analyzed by HPLC, and the solid content was 4.0%, and the mass percentage of raffinose was 33.7% on a dry basis.

[0075] Finally, add deionized water from the top of the percolation column to replace the residual ethanol in the defatted cottonseed meal,...

Embodiment 3

[0078] (1), (2) operating conditions are identical with embodiment 1.

[0079] (3) Put about 1700 grams of HZ802 resin (adsorbent B) into an adsorption column with a size of Φ5.6cm×97cm, and the column bed volume B'V' is about 2400mL.

[0080] Pass the decolorized solution obtained in step (2) into a fixed bed with HZ802 resin (adsorbent B) at a flow rate of 1.5B'V' / h, the sample loading volume is about 2.0B'V', and the temperature is controlled at 40 ℃, the raffinose is adsorbed by the HZ802 resin, and the effluent collected during the sample loading process also contains a small amount of raffinose, which can be directly recycled.

[0081] After loading the sample, wash the adsorption column with 2B'V' deionized water at a flow rate of 1.5B'V' / h to remove the decolorization solution remaining in the adsorbent voids in the adsorption column. The obtained washing solution can be recycled, and finally use 3B' The volume percent concentration of V' is 40% ethanol aqueous soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com