Borosilicate glass suitable for electric light source

A borosilicate glass and borosilicate glass technology, which is applied in the field of glass materials, can solve the problems of corrosion of furnace refractories, deterioration of glass strength and performance, and non-compliance with environmental protection requirements, etc., and achieves long frit properties and low forming. Temperature starting point, effect of good UV absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

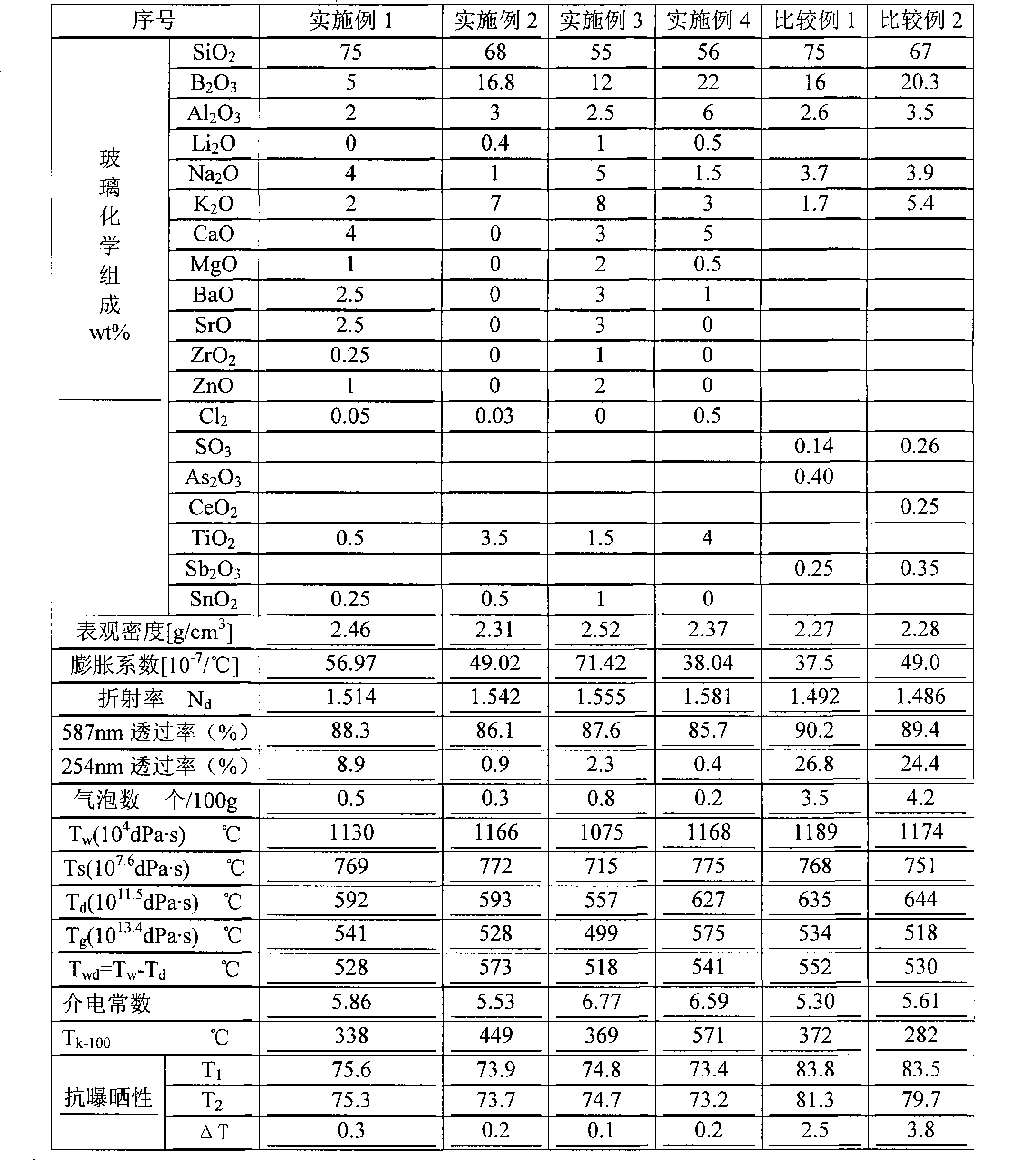

[0042] The present invention is described based on the embodiments, and Table 1 is the composition and performance of the embodiments of the present invention and comparative examples. First, select the raw material according to the glass composition of Example 1 in Table 1, the raw material requirements, quartz sand (150 μm oversize is less than 1%, 45 μm undersize is less than 30%), aluminum hydroxide or aluminum oxide (average particle size 50 μm) , boric acid or borax (400μm sieve is less than 10%, 63μm sieve is less than 10%), calcium carbonate (average particle size 250μm), strontium carbonate (average particle size 20μm) sieve is less than 1%, 50μm ) undersize is 5% or less), barium carbonate (average particle size 50 μm), zinc oxide (average particle size 10 μm oversize is 1% or less), as other glass components, reagent grade magnesium carbonate, magnesium oxide, Sodium Chloride, Ammonium Chloride, Barium Chloride, Zinc Chloride, Lithium Carbonate, Lithium Hydroxide, S...

Embodiment 2

[0060] The actual composition of the glass refers to Example 2 in Table 1. According to the chemical composition of the glass in Example 2 in Table 1, for every 300g of glass liquid prepared, 205.5g of quartz sand, 18.9g of borax, 78.6g of boric acid, 13.8g of aluminum hydroxide, hydrogen Lithium oxide 3g, potassium carbonate 26.3g, titanium oxide 10.7g. The clarifying agent selected is calcium chloride and tin oxide, and the consumption of calcium chloride is 0.15g, and the consumption of tin oxide is 0.75g, and the consumption of potassium nitrate is 7.5g, makes its batching meet the glass chemical composition of table 1 embodiment 2, uses and The same preparation process and evaluation method as in Example 1, the basic properties of the samples are shown in Table 1.

[0061] On the whole, compared with Comparative Example, Example 2 has a good glass clarification effect, the number of bubbles per 100 grams of glass is less than 1, has good visible light transmittance, good ...

Embodiment 3

[0063]According to the glass chemical composition of Example 3 in Table 1, for every 300g of molten glass prepared, 166.5g of quartz sand, 23.6g of borax, 52g of boric acid, 11.7g of aluminum hydroxide, 18g of lithium hydroxide, 35.9g of potassium carbonate, calcium carbonate 16.4g, magnesium oxide 6.2g, barium carbonate 11.9g, strontium carbonate 12.4g, zirconium silicate 4.7g, zinc oxide 6.1g, titanium oxide 4.5g. The clarifying agent selected is tin oxide, the amount of tin oxide is 3g, and the amount of sodium nitrate is 12g, so that its ingredients meet the glass chemical composition of Example 3 in Table 1, using the same preparation process and evaluation method as in Example 1, shown in Table 1 The basic performance of the sample.

[0064] On the whole, compared with Comparative Example, Example 3 has a better glass clarification effect, the number of bubbles per 100 grams of glass is less than 1, has good visible light transmittance, good ultraviolet blocking properti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com