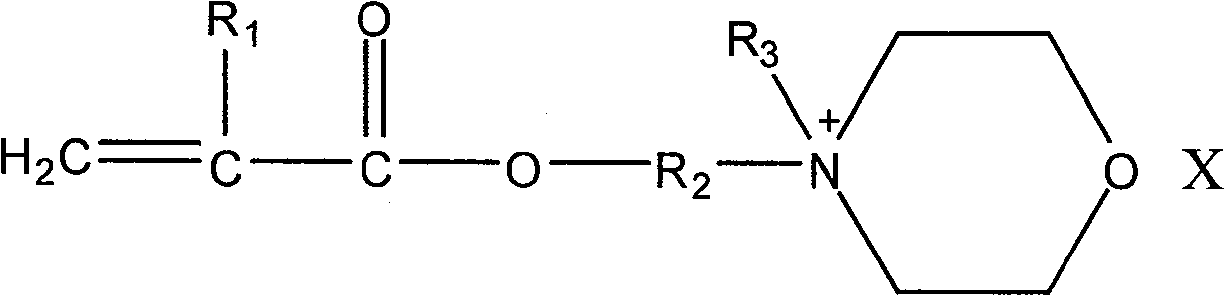

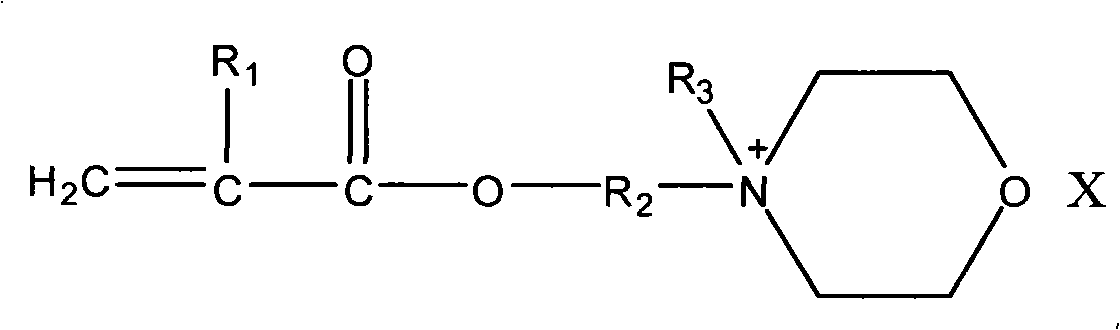

Amphoteric or cationic polymeric flocculating agent

A polymer flocculant, cationic technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., to achieve the effect of high phase transformation ability, strong adsorption capacity and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 23.75g of deionized water, 1.1875g of acrylamide, 0.0375g of morpholine ethyl acrylate hydrochloride and 0.025g of acrylic acid into a stoppered graduated test tube with a capacity of 25ml, dissolve and mix well. Use 1 mol / L NaOH solution and 1 mol / L hydrochloric acid to adjust the pH value of the aqueous solution of the polymerization reaction system to 2, cool in an ice-water bath, and pass nitrogen gas for 15 minutes to remove oxygen. Join 1.875×10 -4 g of potassium persulfate and 0.855×10 -4Oxidation-reduction initiator system composed of sodium sulfite of g, stop the nitrogen gas flow and plug the test tube tightly to prevent air from entering, polymerize for 6 hours at 20°C, and obtain a translucent colloid, which is an amphoteric polymer with high-efficiency phase transition ability. The colloid of the flocculant; the powder of the amphoteric polymer flocculant is obtained after the colloid is granulated, dried, crushed, and sieved. It has high phase transit...

Embodiment 2

[0028] Add 22.5g deionized water, 2.125g acrylamide, 0.225g morpholine ethyl acrylate methyl quaternary ammonium salt and 0.025g acrylic acid into a stoppered graduated test tube with a capacity of 25ml, dissolve and mix well. Use 1 mol / L NaOH solution and 1 mol / L hydrochloric acid to adjust the pH value of the aqueous solution of the polymerization reaction system to 7.4, cool in an ice-water bath, and pass nitrogen gas for 20 minutes to remove oxygen. Join 0.208×10 -4 g of ammonium persulfate and 0.095×10 -4 Oxidation-reduction initiator system composed of sodium sulfite of g, stop the nitrogen flow and plug the test tube stopper tightly to prevent air from entering, and react at 25°C for 6 hours to obtain a translucent colloid, which is an amphoteric polymer flocculation with high-efficiency phase transition ability. The colloid of the agent; the colloid is granulated, dried, crushed and sieved to obtain the powder of the amphoteric polymer flocculant, which has high phase...

Embodiment 3

[0030] Add 20g of deionized water, 2.5g of methacrylamide, 2.25g of morpholine ethyl acrylate hydrochloride and 0.25g of 2-acrylamido-2-methylpropanesulfonic acid into a stoppered graduated test tube with a capacity of 25ml, Dissolve and mix well. Use 1 mol / L NaOH solution and 1 mol / L hydrochloric acid to adjust the pH value of the aqueous solution of the polymerization reaction system to 7.0, cool in an ice-water bath, and pass nitrogen gas for 25 minutes to remove oxygen. Add 0.832×10 -4 g potassium persulfate and 0.18×10 -4 For an oxidation-reduction initiator system composed of sodium sulfite, stop the nitrogen flow and plug the test tube tightly to prevent air from entering, and react at 5°C for 12 hours to obtain a translucent colloid, which is an amphoteric polymer flocculant with high-efficiency phase transition ability. The colloid; the colloid is granulated, dried, pulverized, and sieved to obtain the powder of the amphoteric polymer flocculant, which has high phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com