Method for preparing high-quality large silicon carbide single crystal and silicon carbide single crystal prepared by same

A silicon carbide single crystal, high-quality technology, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc. It can meet the problems of stable growth of high-quality large SiC single crystal, uniformity of radial temperature distribution of difficult seed crystals, etc., and achieve the effect of single crystal form, strong binding force, and improved temperature field uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

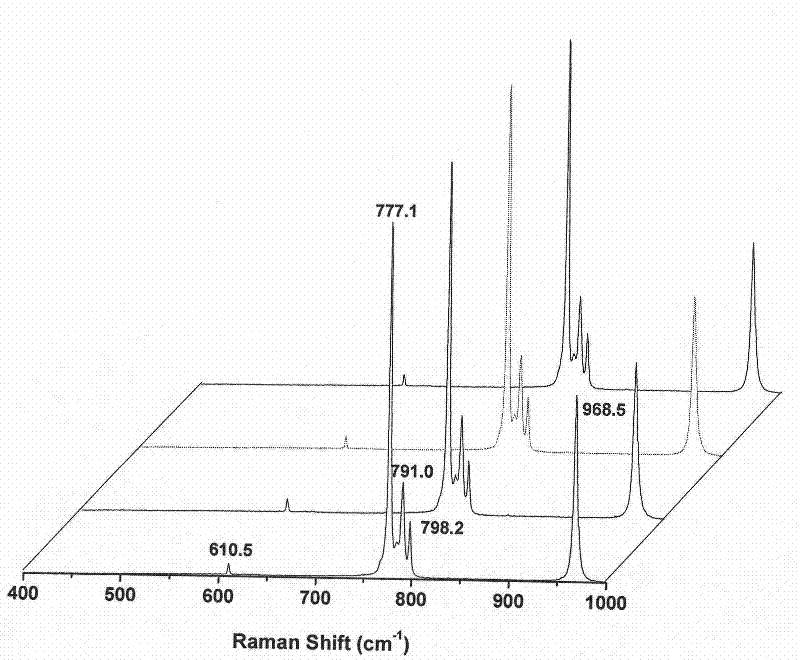

[0040] A modified phenolic resin was used to bond the 6H-SiC seed crystal to grow a 6H-SiC single crystal.

[0041] This embodiment implements according to the preferred embodiment in the summary of the invention:

[0042] In step (1), the resin adopts the phenolic resin modified by salicylaldehyde and Resorcinarenes calixarene;

[0043] In step (2), the seed crystal adopts 6H-SiC on the (0001) Si surface;

[0044]In step (3), heat to 180°C for heat curing, and form a highly cross-linked three-dimensional network resin structure after curing, which can firmly and densely bond the 6H-SiC seed crystal and the seed crystal frame together;

[0045] In step (6), in an argon atmosphere, heat up at a certain heating rate (generally less than 10°C / h), gradually heat to 1200°C, slowly pyrolyze and carbonize, and the residual carbon rate of the resin is 73%;

[0046] In step (7), put the carbonized and bonded 6H-SiC seed crystal and the seed crystal frame into the graphite crucible fi...

Embodiment 2

[0049] A modified furfuryl ketone resin was used to bond 4H-SiC seed crystals to grow 4H-SiC single crystals.

[0050] This embodiment implements according to the preferred embodiment in the summary of the invention:

[0051] In step (1), resin adopts the modified furfuryl ketone resin formed by condensation of cyclohexanone, urea, formaldehyde and furfuryl alcohol, the first step is the synthesis of ketone aldehyde resin, the second step is the synthesis of pulse aldehyde resin, the third step It is the polycondensation of furfurone resin to obtain modified furfurone resin;

[0052] In step (2), the seed crystal adopts 4H-SiC with a carbon surface of (0001);

[0053] In step (3), heat to 150°C for heat curing, and form a highly cross-linked three-dimensional network resin structure after curing, which can firmly and densely bond the 4H-SiC seed crystal and the seed crystal frame together;

[0054] In step (6), in a nitrogen atmosphere, heat up at a certain heating rate (gen...

Embodiment 3

[0058] A modified epoxy resin was used to bond the 15R-SiC seed crystal to grow a 15R-SiC single crystal.

[0059] This embodiment implements according to the preferred embodiment in the summary of the invention:

[0060] In step (1), resin adopts the epoxy resin modified with cyanate ester;

[0061] In step (2), the seed crystal is 15R-SiC with (0001) silicon surface;

[0062] In step (3), heat to 250°C for heat curing, and form a highly cross-linked three-dimensional network resin structure after curing, which can firmly and densely bond the 15R-SiC seed crystal and the seed crystal frame together;

[0063] In step (6), in a nitrogen atmosphere, the temperature is raised at a certain heating rate (generally less than 7°C / h), gradually heated to 800°C, slowly pyrolyzed and carbonized, and the residual carbon rate of the resin is 65%;

[0064] In step (7), put the carbonized and bonded 15R-SiC seed crystal and the seed crystal frame into the graphite crucible filled with raw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| carbon residual rate | aaaaa | aaaaa |

| carbon residual rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com