Composite material used in soil remediation and preparation method thereof

A technology of composite material and porous composite material, which is applied in the field of preparation of the material, can solve the problems of fertilizer component loss, increase soil fertility, and difficulty in improving soil structure, so as to improve soil structure, increase soil fertility, and facilitate circulation Utilization and Sustainability Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

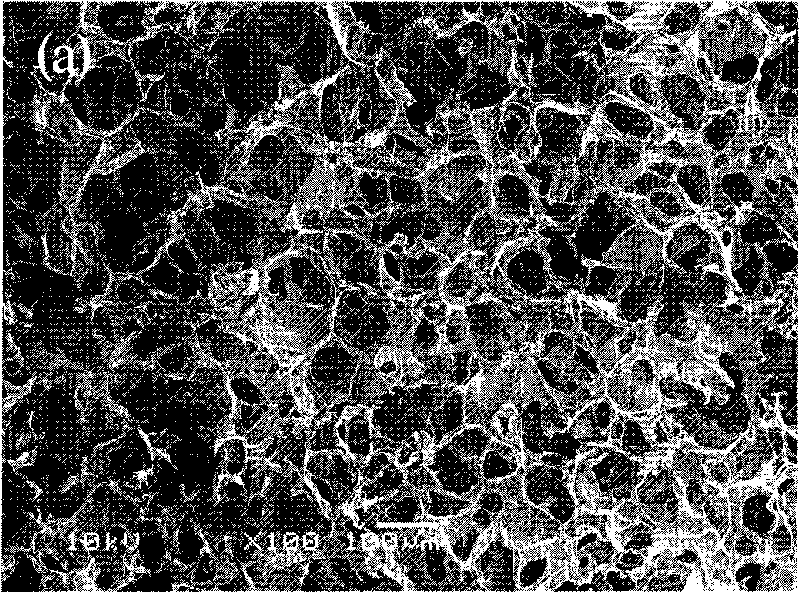

Embodiment 1

[0028] Sodium carboxymethyl cellulose 4g was dissolved in 250g deionized water at 60°C. After dissolving 6g of chitosan (90% degree of deacetylation) in 150g of 2% acetic acid aqueous solution, gradually add it into the carboxymethyl cellulose solution, and obtain a clear and transparent sol system after reacting for 3 hours. Slowly drop from room temperature to -20°C within hours, and keep at -20°C for at least 12 hours, take it out and put it in a freeze dryer (-50°C, 10Pa) to lyophilize. After washing with deionized water to neutrality, its water absorption rate is measured to be 2613.5±91.3%. Under the condition of ventilation and drying at 40°C, the water retention time is about 3.5 hours when the water retention capacity is 40%. The porosity of the obtained composite material is 90%-95%.

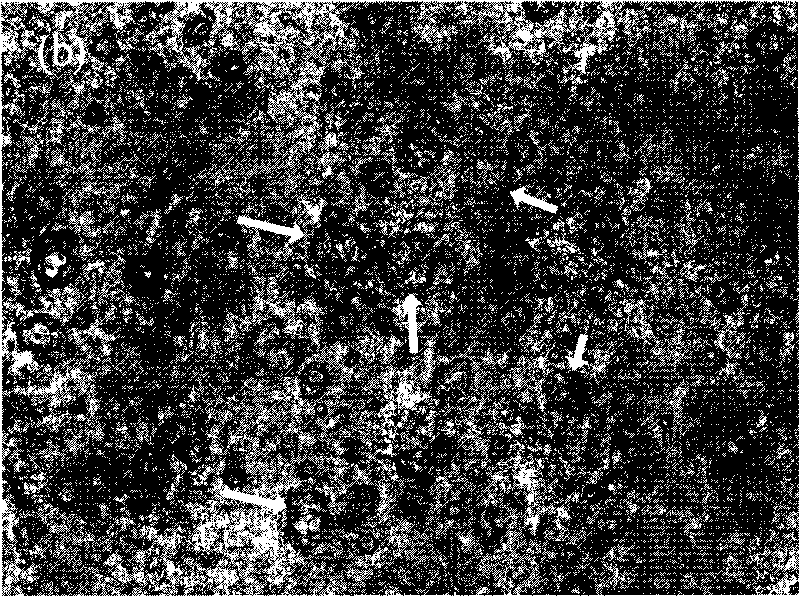

[0029] After the obtained porous composite material was sterilized by ethylene oxide, Pseudomonas and Alcaligenes faecalis were inoculated at a density of 100 million per gram at the ...

Embodiment 2

[0031] Sodium carboxymethyl cellulose 5g is dissolved in 250g deionized water at 60 DEG C. After chitosan (degree of deacetylation is 95%) 5g is dissolved in 2% formic acid aqueous solution of 150g, add in the carboxymethyl cellulose sol gradually, After reacting for 3 hours, a clear and transparent sol system was obtained, which was left standing to defoam. After fully cooling at 4°C, the temperature was then lowered to -10°C and kept for at least 8 hours, and finally cooled to -20°C and kept for at least 8 hours, then taken out and placed for freeze-drying Freeze-dried in the machine (-45°C, 10Pa). After washing with deionized water to neutrality, the porosity is 90%-95%, the water absorption rate is 1768.7±127.6%, and the water retention is 40% under the condition of ventilation and drying at 40°C. % water retention time is about 3.5h. The composite material is sterilized by ethylene oxide, inoculated with Pseudomonas at a density of 200 million / g, cultured in an incubator a...

Embodiment 3

[0034] Dissolve 6g of carboxymethyl cellulose in 250g of deionized water at 60°C, dissolve 4g of carboxymethyl chitosan in 150g of aqueous solution, and gradually add it to the carboxymethyl cellulose sol, and obtain a clear and transparent sol system after reacting for 3 hours , let stand to remove bubbles, after fully cooling at 4°C, then lower the temperature to -20°C and keep it for at least 8-12 hours, take it out and freeze-dry it in a freeze dryer (-50°C, 8Pa). After washing with deionized water to neutrality, the porosity is 90%-95%, the water absorption is 2202.4±128.6%, and the water retention time is about 3 hours when the water retention is 40% at 40°C under ventilated and dry conditions. The composite material was sterilized by ethylene oxide, and inoculated with Agrobacterium and Alcaligenes faecalis at a density of 100 million per gram at the same time, cultured in an incubator at 30°C for 1 day, and then centrifuged to separate the bacteria plate count, with a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com