Clonidine multivesicular liposome and preparation method thereof

A multivesicular liposome and clonidine technology, applied in the field of clonidine multivesicular liposome and its preparation, can solve the problems of low utilization rate of raw materials, low utilization rate of drugs, etc., and achieve high utilization rate of raw materials and less waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

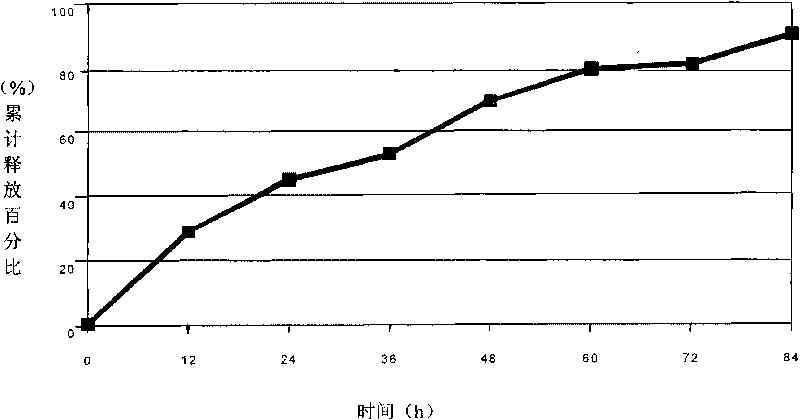

Examples

Embodiment 1

[0054] Step 1: In a clean glass vessel add 1 mL containing 19.8mM (14.85mg) lecithin, 4.2mM (3.13mg) dipalmitoylphosphatidylglycerol, 30mM (11.61mg) cholesterol and 3.75mM (3.32mg) trioleic acid Chloroform solution of glycerides. This solution is called the lipid phase.

[0055] Step 2: Add 1mL of the internal water phase of the aqueous solution of 120mM (15.86mg) ammonium sulfate into the above-mentioned glass container containing the lipid phase, and stir at a speed of 10,000rpm for 10 minutes with a high-speed shearer to obtain W / O type colostrum.

[0056] Step 3: 5 mL of a solution containing 5% (w / v) (250 mg) glucose and 40 mM (29.36 mg) lysine was placed on the colostrum layer, and then mixed at a speed of 7500 rpm for 10 seconds to obtain W / O / W type double milk.

[0057] Step 4: Transfer the double emulsion to a 250mL Erlenmeyer flask containing 7mL containing 5% (w / v) (350mg) glucose and 40mM (40.93mg) lysine, in a constant temperature water bath at 37°C, and make ...

Embodiment 2

[0062] Step 1: Add 1 mL of 5 mM (3.96 mg) Hydrogenated Soy Lecithin, 0.5 mM (0.38 mg) Dipalmitate Phosphatidylserine, 10 mM (3.87 mg) Cholesterol and 0.155 mM (0.073 mg) Tricaprylic Glycerin to a clean glass container Esters in chloroform-ether solution. This solution is called the lipid phase.

[0063] Step 2: Add 0.5mL of the inner water phase of the aqueous solution of 10mM manganese sulfate (0.845mg) and 6% (w / v) (600mg) sucrose into the above-mentioned glass container containing the lipid phase, and use a high-speed shearing machine to Stir at a speed of 10,000 rpm for 10 minutes to obtain W / O colostrum.

[0064] Step 3: 7.5 mL of a solution containing 0.5% (w / v) (37.5 mg) mannitol and 80 mM (87.71 mg) lysine was placed on the colostrum layer, and then mixed at a speed of 4500 rpm for 40 seconds to obtain W / O / W type double emulsion.

[0065] Step 4: Transfer the double emulsion to a 250mL Erlenmeyer flask containing 9mL containing 0.5% (w / v) (45mg) mannitol and 80mM (...

Embodiment 3

[0070] Step 1: Add 1 mL of a dichloromethane solution containing 100 mM (75 mg) lecithin, 20 mM (8.49 mg) phosphatidic acid, 10 mM (3.87 mg) cholesterol and 13 mM (11.51 mg) triolein into a clean glass container. This solution is called the lipid phase.

[0071] Step 2: Add 1mL of the inner water phase of the aqueous solution with 1000mM (192.1mg) citric acid into the above-mentioned glass container containing the lipid phase, and stir at a speed of 10,000rpm for 10 minutes with a high-speed shearer to obtain a W / O type colostrum.

[0072] Step 3: 20 mL of a solution containing 10% (w / v) (2000 mg) mannitol and 20 mM (58.48 mg) lysine was placed on the colostrum layer, and then mixed at a speed of 7500 rpm for 20 seconds to obtain W / O / W type double milk.

[0073] Step 4: Transfer the double emulsion to a 1000mL Erlenmeyer flask containing 22mL containing 10% (w / v) (2200mg) mannitol and 20mM (64.32mg) lysine. Flow through the suspension in the Erlenmeyer flask, slowly evapor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com