Processing method and processing system thereof for acidic waste water containing heavy metals

A technology of acid wastewater and treatment method, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as process accidents, blockage of water pipelines, damage to treatment equipment, etc. Achieve the effect of stable process operation, reduce processing cost and increase pH value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Treatment of a non-ferrous smelting wastewater

[0057] The pH value of a copper smelting wastewater to be treated is 2.45, and the contents of As, Cd, Cu and Zn are 5463mg / L, 808.20mg / L, 373.30mg / L and 3198.0mg / L respectively.

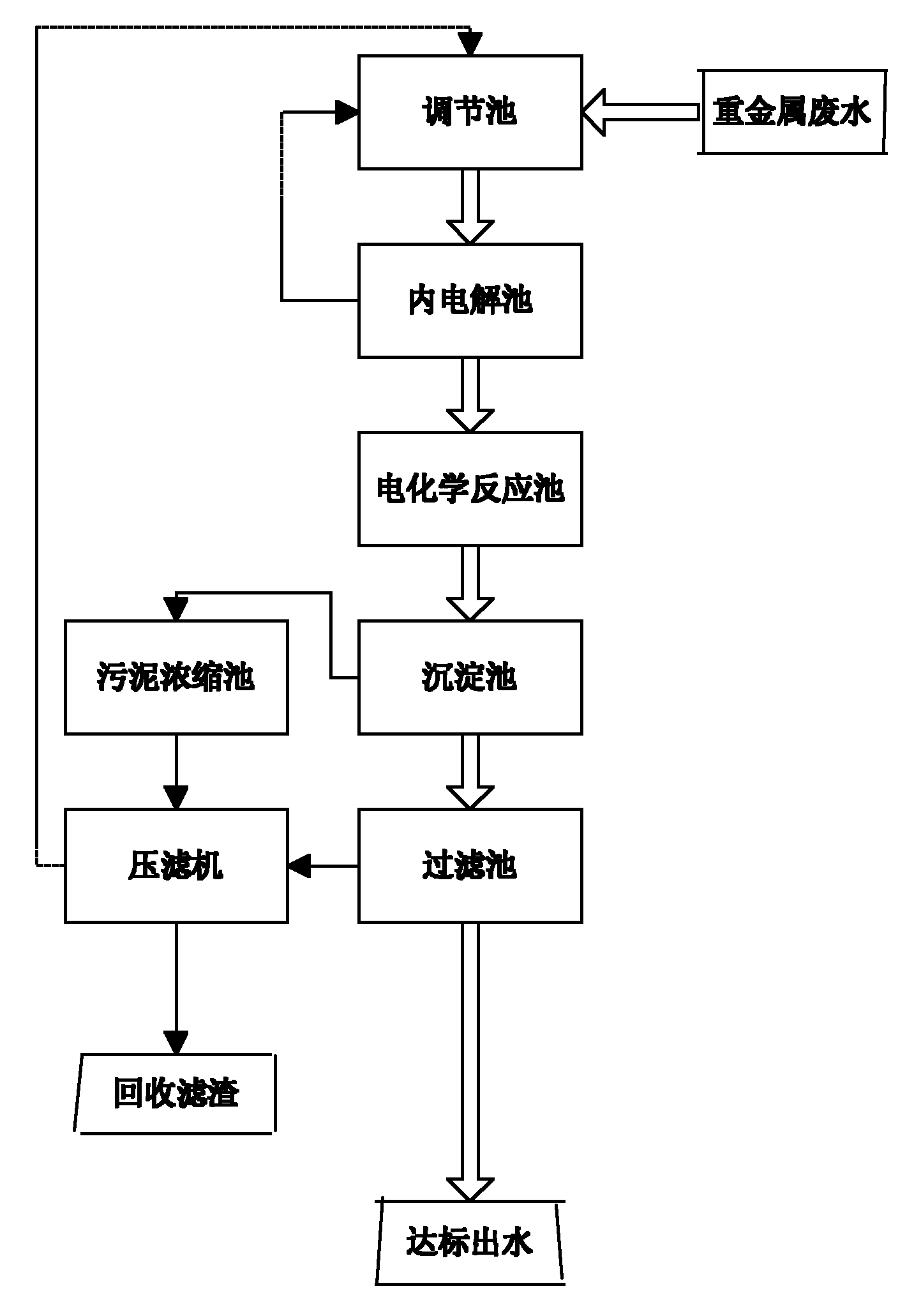

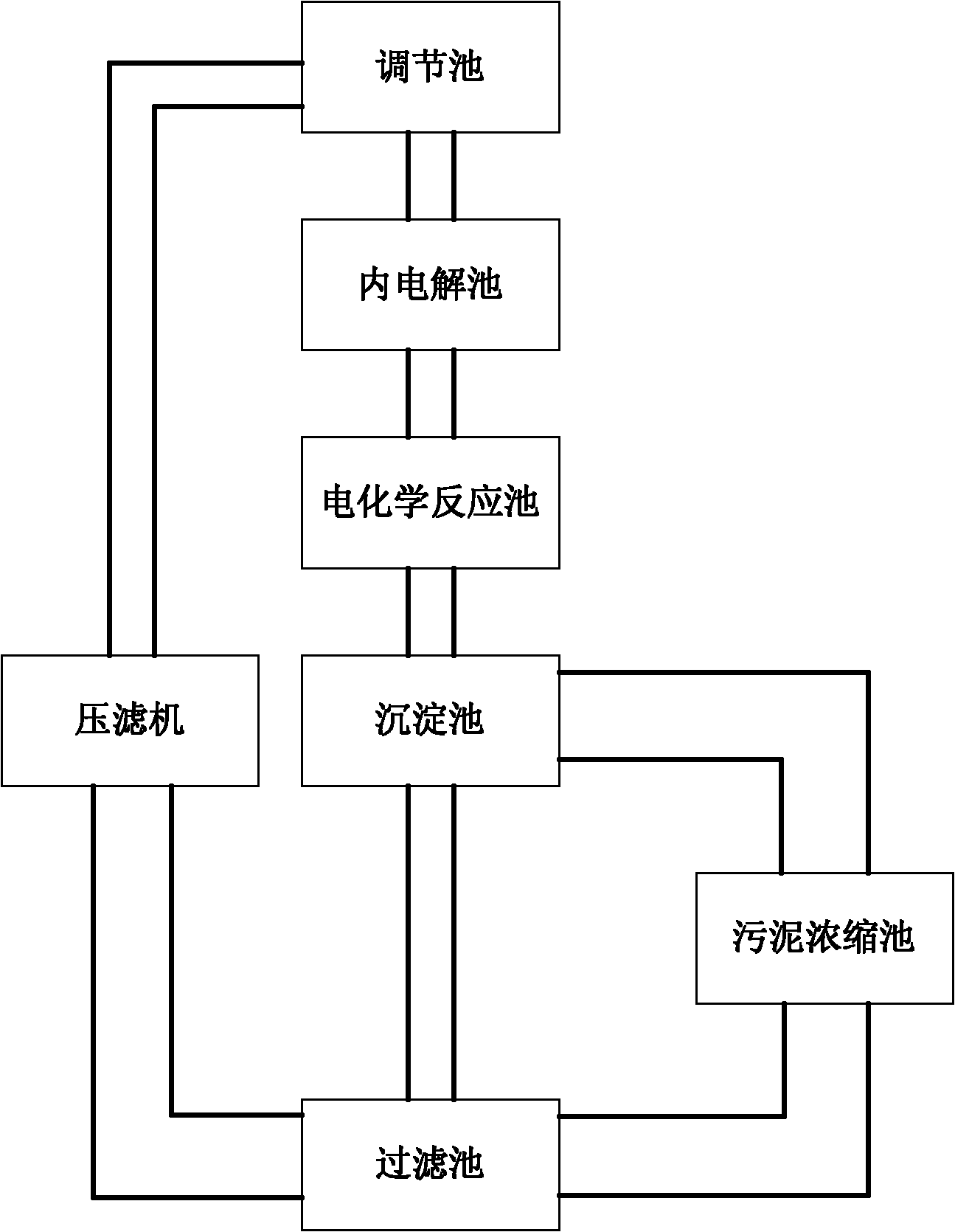

[0058] A kind of treatment system that is used for the wastewater treatment of the present embodiment as shown in Figure 2, and this treatment system comprises the regulation pond, internal electrolysis pond, electrochemical reaction pond, sedimentation pond and filter pond that are connected successively, each treatment pond is A water inlet and a water outlet are provided, and the treatment pools are connected by pipes (or ditches, etc.); wherein, a reaction bed is provided in the inner electrolytic pool, and the reaction bed is filled with zeolite modified by cationic surfactants, The filter material is composed of carbon powder and iron filings, the mass ratio of carbon powder and iron filings is 1:10, and the modified zeolite content is 1%...

Embodiment 2

[0069] Treatment of an electroplating wastewater

[0070] The pH value of a certain electroplating wastewater to be treated is 3.43, where Cr 6+ , Zn, Ni, and Cu contents were 26.0mg / L, 56.4mg / L, 90.8mg / L, and 8.28mg / L, respectively.

[0071] The method for processing the above-mentioned electroplating wastewater to be treated using the treatment system in Example 1 specifically comprises the following steps:

[0072] (1) Pretreatment: the electroplating wastewater is transported to a water quality adjustment pool, and the large particles and impurities in the wastewater are removed through grid pretreatment;

[0073] (2) Internal electrolytic treatment: input the pretreated effluent into the internal electrolytic cell, so that the effluent flows through the reaction bed provided in the internal electrolytic cell. Under aeration conditions, the reaction time in the internal electrolytic cell is controlled to 15min. The effluent after internal electrolysis treatment enters th...

Embodiment 3

[0081] Treatment of a strong acidic heavy metal wastewater

[0082] A strong acidic heavy metal wastewater to be treated has a pH value of 0.3, and the contents of As, Cd, Zn, and Cu are 66.6mg / L, 111.7mg / L, 32.1mg / L, and 757.1mg / L, respectively.

[0083] The method for processing the above-mentioned strongly acidic heavy metal wastewater to be treated using the treatment system in Example 1 specifically comprises the following steps:

[0084] (1) Pretreatment: the strong acidic heavy metal wastewater is transported to a water quality adjustment tank, and the large particles and impurities in the wastewater are removed through grid pretreatment;

[0085] (2) Internal electrolytic treatment: input the pretreated effluent into the internal electrolytic cell, make the effluent flow through the reaction bed set in the internal electrolytic cell, under aeration conditions, the reaction time in the internal electrolytic cell is controlled to 30min, Part of the treated water after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com