SEBS thermoplastic elastomer cable insulation material and preparation method thereof

A thermoplastic elastomer, cable insulation technology, used in plastic/resin/wax insulators, organic insulators, etc., can solve the problems of easy scorch, less localized products, complicated process flow, etc., and achieve excellent heat resistance and weather resistance. , the effect of significant economic and social benefits and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

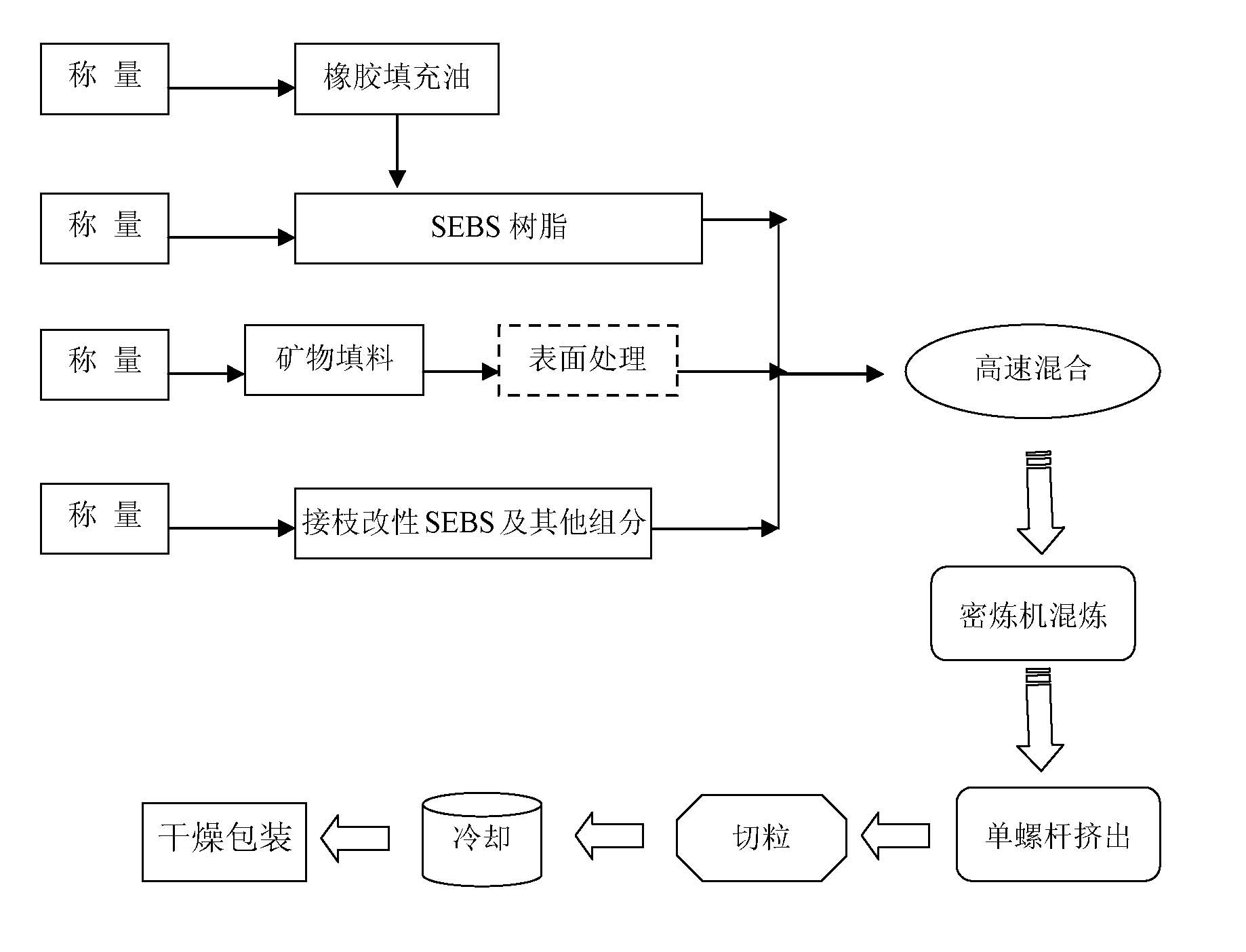

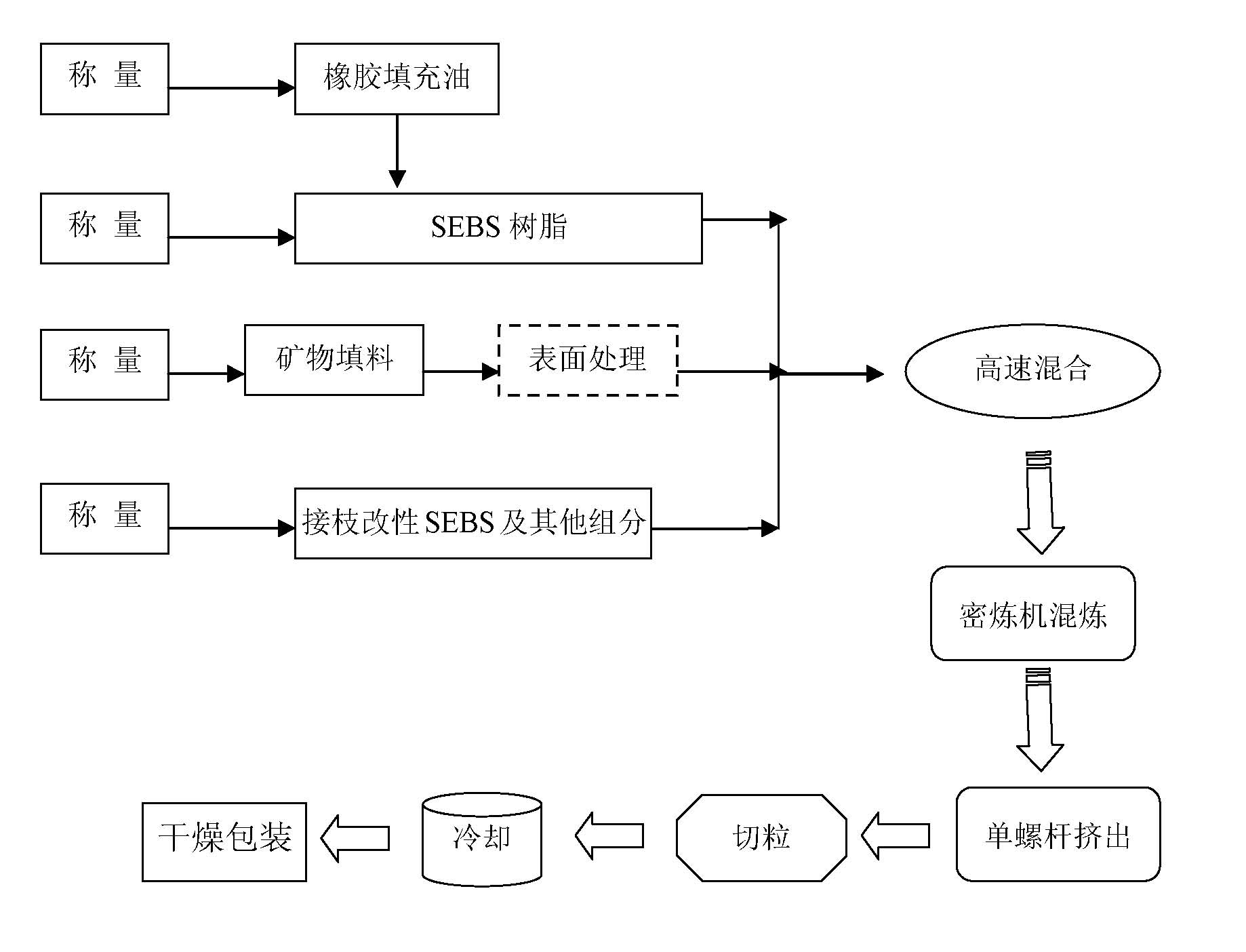

[0052] The invention also discloses the preparation method of the above-mentioned SEBS thermoplastic elastomer cable insulating material, and the process flow chart is as follows: figure 1 described, including the following steps:

[0053] Weighing raw materials: Weigh 100 parts of raw material SEBS resin, 50-150 parts of rubber filler oil, 10-50 parts of graft modified SEBS, 50-80 parts of polypropylene, 15-30 parts of polyolefin elastomer, 100-200 parts of mineral filler parts, lubricants 2~5 parts, anti-aging agent 2~4 parts, copper ion inhibitor 1.8~3 parts.

[0054] Mixing: Make the SEBS resin fully absorb the rubber filler oil, or optionally surface-treated the mineral filler, and then add it to the mixer together with other components and mix well.

[0055] Granulation: kneading with an internal mixer, extruding and granulating with a single-screw extruder with forced feeding, and finally drying and packaging.

[0056] Preferably, in the granulation step, the internal...

Embodiment 1

[0059] Weighing raw materials: weigh 100 parts by weight of high molecular weight SEBS resin, 125 parts by weight of paraffin-based rubber oil, 35 parts by weight of maleic anhydride grafted SEBS, 72 parts by weight of copolymerized polypropylene, 21 parts of EPDM rubber, 150 parts of calcined kaolin parts, 1 part by weight of ethylene bis-stearic acid amide, 1 part by weight of zinc stearate, 1 part by weight of polyethylene wax, tetrakis[beta-3-(3,5-di-tert-butyl-4-hydroxyphenyl) Propionic acid] 1.5 parts by weight of pentaerythritol, 1 part by weight of bis(2,4-di-tert-butylphenyl) pentaerythritol diphosphite, 1.2 parts by weight of N-salicylaminophthalimide, N,N' -1.0 part by weight of bis[beta(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl]hydrazide.

[0060] Mixing: Make the SEBS resin completely absorb the paraffin-based rubber oil, then add it together with the maleic anhydride grafted SEBS and other components into the mixer and mix it evenly.

[0061] Granulation: knea...

Embodiment 2

[0065] Weigh the raw materials: Weigh the raw materials according to the predetermined weight parts: 50 parts by weight of high molecular weight SEBS resin, 50 parts by weight of low molecular weight SEBS resin, 150 parts by weight of naphthenic rubber oil, 10 parts by weight of acrylic acid grafted SEBS, homopolymeric polymer 50 parts by weight of propylene, 30 parts by weight of EPDM rubber, 100 parts by weight of silk powder, 100 parts by weight of muscovite powder, 1.5 parts by weight of ethylene bisoleamide, 1.5 parts by weight of calcium stearate, 1 weight part of PE wax parts, 1 part by weight of dimethicone, 1 part by weight of octadecyl β(4-hydroxy-3,5-di-tert-butylphenyl)propionate, 1 part by weight of tris(2,4-di-tert-butylphenyl)idene 1 part by weight of phosphoric acid ester and 1.8 part by weight of N-salicylamidophthalimide.

[0066] Mixing: First make the SEBS resin completely absorb the naphthenic rubber oil, then add it together with the acrylic grafted SEBS ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com