Steel slag eco-concrete, steel slag eco-concrete product and preparation method thereof

An ecological concrete and steel slag technology, which is applied in the field of steel slag ecological concrete and the preparation of steel slag ecological concrete products, can solve the problems such as the inability to exert harmful ion adsorption and detoxification, the failure to utilize the cementitious properties of steel slag, and the suppression of damage stress. , to achieve good ecological restoration effect, good water treatment effect, and the effect of reducing sludge production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

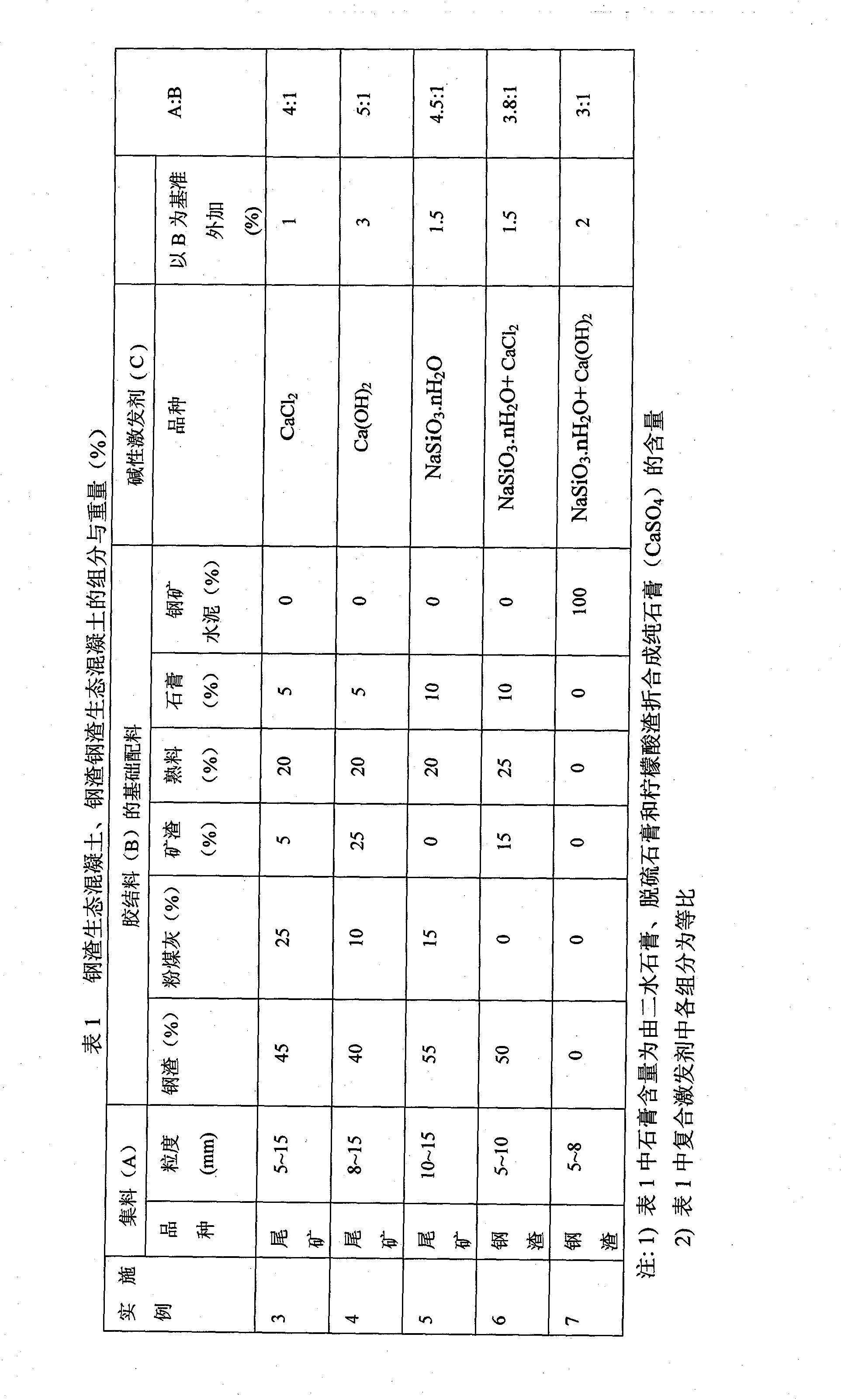

Examples

Embodiment 1

[0044] 1) Prepare mixed microbial powder according to the following method:

[0045] Take the sludge where the microbial activity is more frequent or the activated sludge of the sewage treatment plant as the sample collection of bacteria, and then through the existing separation and screening technology, the first directional isolation containing Bacillus, nitrifying bacteria, photosynthetic bacteria and actinomycetes , Yeast, lactic acid bacteria, and select the dominant flora among them, and then carry out the stepwise alkali resistance domestication to obtain alkali-resistant bacillus, nitrifying bacteria, photosynthetic bacteria, actinomycetes, yeasts, Six types of microorganisms, including lactic acid bacteria, are finally mixed fermentation. During fermentation, photosynthetic bacteria are used as the main bacteria to deal with the pollution characteristics of high concentration of small molecular organic matter in the water body. The six types of microorganisms obtained are...

Embodiment 2

[0054] The method for preparing the mixed slurry of the microbial flora, the microbial flora and the culture medium is basically the same as that of the specific embodiment 1, except that the ratio of each flora is different during mixed fermentation. During the fermentation, according to the characteristics of water pollution, which is mainly to deal with nitrite pollution, nitrifying bacteria are used as the main bacteria, and the six types of microorganisms obtained are respectively subjected to primary seed culture and secondary multiplication culture, according to 45 parts of nitrifying bacteria and photosynthetic bacteria. 15 parts, 25 parts of bacillus, 5 parts of actinomycetes, 5 parts of yeasts, and 5 parts of lactic acid bacteria. Add them to the mixed fermentation tank, ferment to obtain a mixed microbial liquid, and then freeze-dry it into a special Treat mixed microbial powder in water polluted by nitrite.

[0055] The above-mentioned mixed microbial powder, culture ...

Embodiment 3

[0063] In view of the pollution characteristics of aquaculture water body with a lot of ammonia nitrogen to be treated, actinomycetes are used as the main bacteria, and the six types of microorganisms obtained are respectively subjected to primary seed culture and secondary multiplication culture, according to 35 parts of actinomyces and 15 parts of photosynthetic bacteria , 20 parts of Bacillus, 20 parts of nitrifying bacteria, 5 parts of yeasts, 5 parts of lactic acid bacteria, add them to the mixed fermentation tank, ferment to prepare a mixed microbial liquid, and then freeze-dry it into a special ammonia nitrogen treatment A lot of mixed microbial powder that pollutes aquaculture water.

[0064] The above-mentioned mixed microbial powder, culture medium paper scraps, and water are mixed in a weight ratio of 1:5:3 and stirred for 1 hour to prepare a mixed slurry of mixed microbial powder and medium.

[0065] Prepare steel slag ecological concrete products according to the follo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com