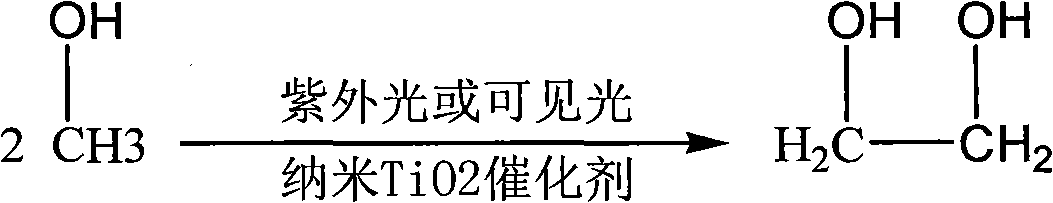

Method for synthesizing ethylene glycol from noble metal load nanometer titanium dioxide through photocatalysis

A nano-titanium dioxide, precious metal technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of poor product selectivity, low conversion rate, loss of activity, etc. To achieve the effect of environmental friendliness, low price and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

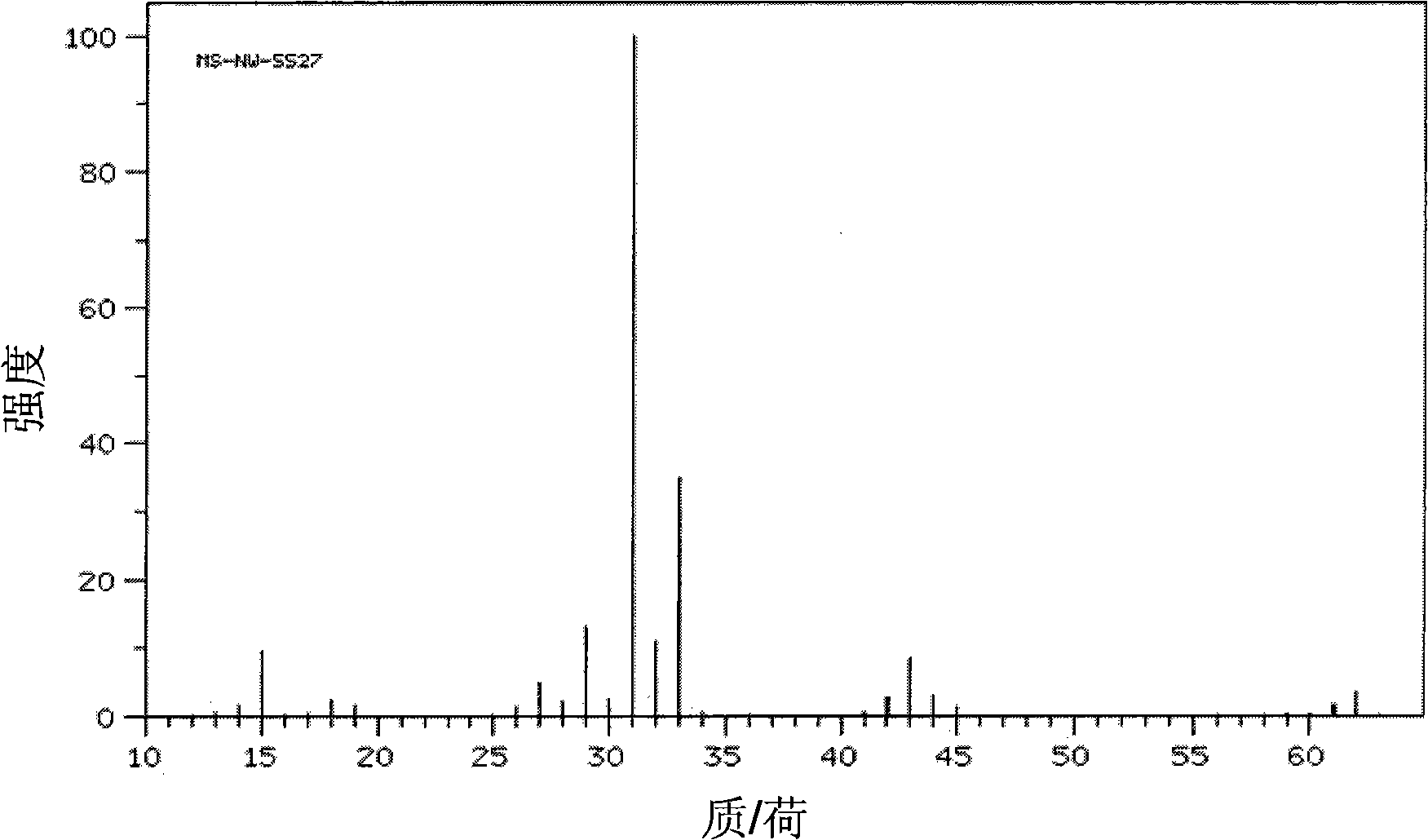

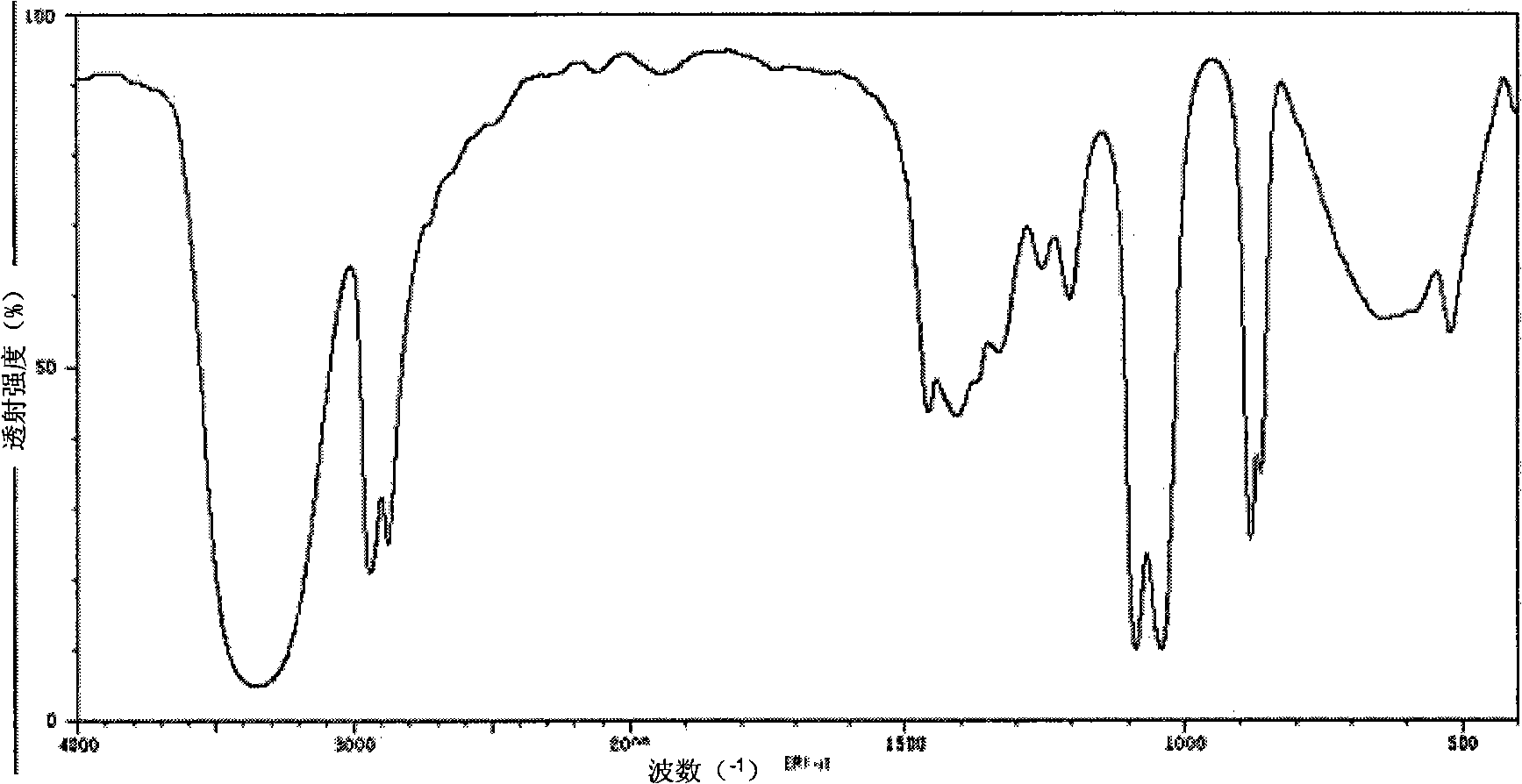

Embodiment 1

[0021] 125ml of isopropanol and 12.5ml of isopropyl titanate were mixed evenly, and under the condition of magnetic stirring and reflux, they were added dropwise in a 500ml round-bottomed flask equipped with water and isopropanol within 30min (the amount of water and isopropanol The ratio is 50:1), after the hydrolysis is complete, continue to stir and reflux for 2h. The reaction solution was transferred into a 50ml polytetrafluoroethylene-lined hydrothermal kettle, reacted at 80°C for 1 day, centrifuged and precipitated, and washed with distilled water to obtain pure anatase nanospheres. Move to a muffle furnace and bake at 1000°C for 10 hours to obtain pure rutile nanospheres. Take 1g of pure rutile TiO 2 The nanospheres were dispersed into 200ml of methanol-water reaction solution with a methanol volume fraction of 30%, and 0.3ml of chloroplatinic acid (1g / 10ml) was added according to the loading capacity of 3%, magnetically stirred and nitrogen gas was introduced. After ...

Embodiment 2

[0023] 125ml of isopropanol and 12.5ml of isopropyl titanate were mixed evenly, and under the condition of magnetic stirring and reflux, they were added dropwise in a 500ml round-bottomed flask equipped with water and isopropanol within 30min (the amount of water and isopropanol The ratio is 50:1), after the hydrolysis is complete, continue to stir and reflux for 2h. The reaction solution was transferred to a 50ml polytetrafluoroethylene-lined hydrothermal kettle, reacted at 80°C for 1 day, centrifuged and precipitated, and washed with distilled water to obtain pure anatase nanorods. Moved to the muffle furnace, roasted at 550°C for 5 hours to obtain TiO with anatase and rutile ratio of 30:70 2 Nano stave. Take 1g of TiO with a ratio of anatase and rutile of 30:70 2 The nanorods were dispersed into 400ml of methanol-water reaction liquid with a methanol volume fraction of 50%, and 0.2ml of palladium chloride (1g / 10ml) was added according to the loading capacity of 2%, and ni...

Embodiment 3

[0025]125ml of isopropanol and 12.5ml of isopropyl titanate were mixed evenly, and under the condition of magnetic stirring and reflux, they were added dropwise in a 500ml round-bottomed flask equipped with water and isopropanol within 30min (the amount of water and isopropanol The ratio is 50:1), after the hydrolysis is complete, continue to stir and reflux for 2h. The reaction solution was transferred to a 50ml polytetrafluoroethylene-lined hydrothermal kettle, reacted at 80°C for 1 day, centrifuged and precipitated, and washed with distilled water to obtain pure anatase nanorods. Move to a muffle furnace and bake at 600° C. for 8 hours to obtain nanorods with a ratio of anatase and rutile of 20:80. Get 1g anatase and rutile ratio and be that 20:80 nanorod is dispersed in the methanol-water reaction solution of 300mL methanol volume fraction 30%, add 0.4ml chloroauric acid (1g / 10ml) by loading capacity 4%, magnetically stir and Vacuum. After removing the oxygen in the syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com