Silicate compound luminescent material and preparation method thereof

A technology of silicate compounds and luminescent materials, applied in luminescent materials, chemical instruments and methods, sustainable buildings, etc., can solve the problems of low effective conversion efficiency, unstable properties, large light decay, etc. Easy to mass-produce, good effect of anti-attenuation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

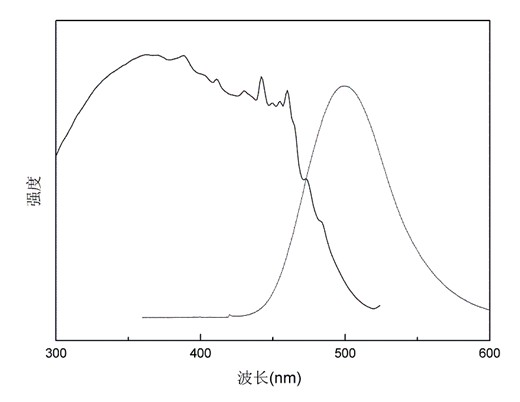

[0031] Example 1: Ba 1.999 SiO 4 : 0.005Eu 2+ Preparation example of luminescent material

[0032] Press Ba 1.999 SiO 4 : 0.001Eu 2+ The stoichiometric ratio takes by weighing 39.369 grams of high-purity barium carbonate and 0.088 grams of europium oxide in dilute nitric acid solution to obtain a nitrate solution; dissolving 20.833 grams of tetraethyl orthosilicate in a certain amount of dehydrated alcohol to obtain a normal calculation ethyl ester solution; Under constant stirring, slowly add tetraethyl orthosilicate solution into the nitrate solution, and then add dilute ammonia water with a volume percentage of 10%, adjust the pH value to 8, and then keep stirring at a constant temperature of 80°C for 3 hours , to obtain a white transparent sol; dry the sol at 150°C to obtain a xerogel, break it into a powder, then add barium fluoride with a mass of 5% of the xerogel and perform ball milling; mix the obtained mixture in the volume of hydrogen The percentage content is...

Embodiment 2

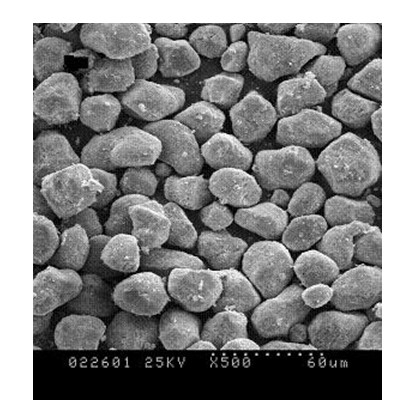

[0034] Example 2: Sr 1.34 Ba 0.6 SiO 4 : 0.06Eu 2+ Preparation example of luminescent material

[0035] Press Sr 1.34 Ba 0.6 SiO 4 : 0.06Eu 2+ The stoichiometric ratio weighed 19.782 grams of strontium carbonate, 11.840 grams of barium carbonate and 0.088 europium oxide in dilute nitric acid solution to obtain a nitrate solution; ester solution; under continuous stirring, slowly add tetraethyl orthosilicate solution into the nitrate solution, and then add dilute ammonia water with a volume percentage of 10% to the above solution, adjust the pH value to 9, and then Stir continuously at a constant temperature for 5 hours to obtain a white transparent sol; dry the sol at 200°C to obtain a xerogel, and after the xerogel is broken into powder, add barium fluoride and 1 % boric acid and mixed by ball milling; the mixture was sintered in a nitrogen-hydrogen mixture in a nitrogen-hydrogen reducing atmosphere (in a nitrogen-hydrogen reducing atmosphere, the volume percentage of...

Embodiment 3

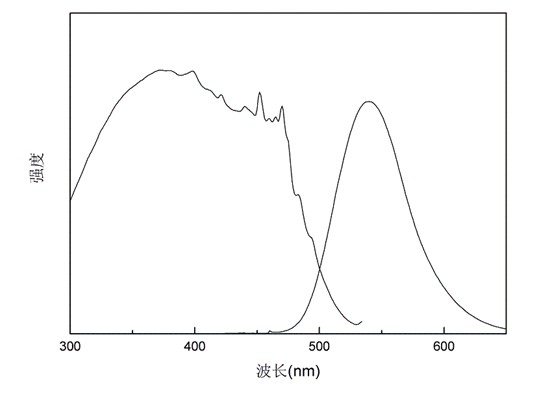

[0037] Example 3: Sr1.7 Ca 0.1 Mg 0.05 SiO 4 : 0.15Eu 2+ Preparation example of luminescent material

[0038] Press Sr 1.7 Ca 0.1 Mg 0.05 SiO 4 : 0.15Eu 2+ The stoichiometric ratio takes 35.977 grams of strontium nitrate, 2.361 grams of calcium nitrate tetrahydrate, 0.202 grams of magnesium oxide and 2.639 grams of europium oxide in dilute nitric acid solution to obtain a nitrate solution; dissolve 20.833 grams of ethyl orthosilicate in a certain amount of Ethyl orthosilicate solution was obtained in water and ethanol; under continuous stirring, slowly add ethyl orthosilicate solution into the nitrate solution, and then add dilute ammonia water with a volume percentage of 10% to the above solution to adjust the pH value Adjust it to 10, and then keep stirring at a constant temperature of 70°C for 4 hours to obtain a white transparent sol; dry the sol at 250°C to obtain a xerogel, and after the xerogel is broken into powder, the added mass is the mass of the xerogel 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com