Method for producing chymosin by aspergillus niger solid fermentation

A technology of solid fermentation and chymosin, which is applied in the field of food biology, can solve the problems of high risk of bacterial contamination in liquid fermentation, difficulty in industrialization, and high cost, and achieve the effects of low hydrolysis capacity, reduced production costs, and low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

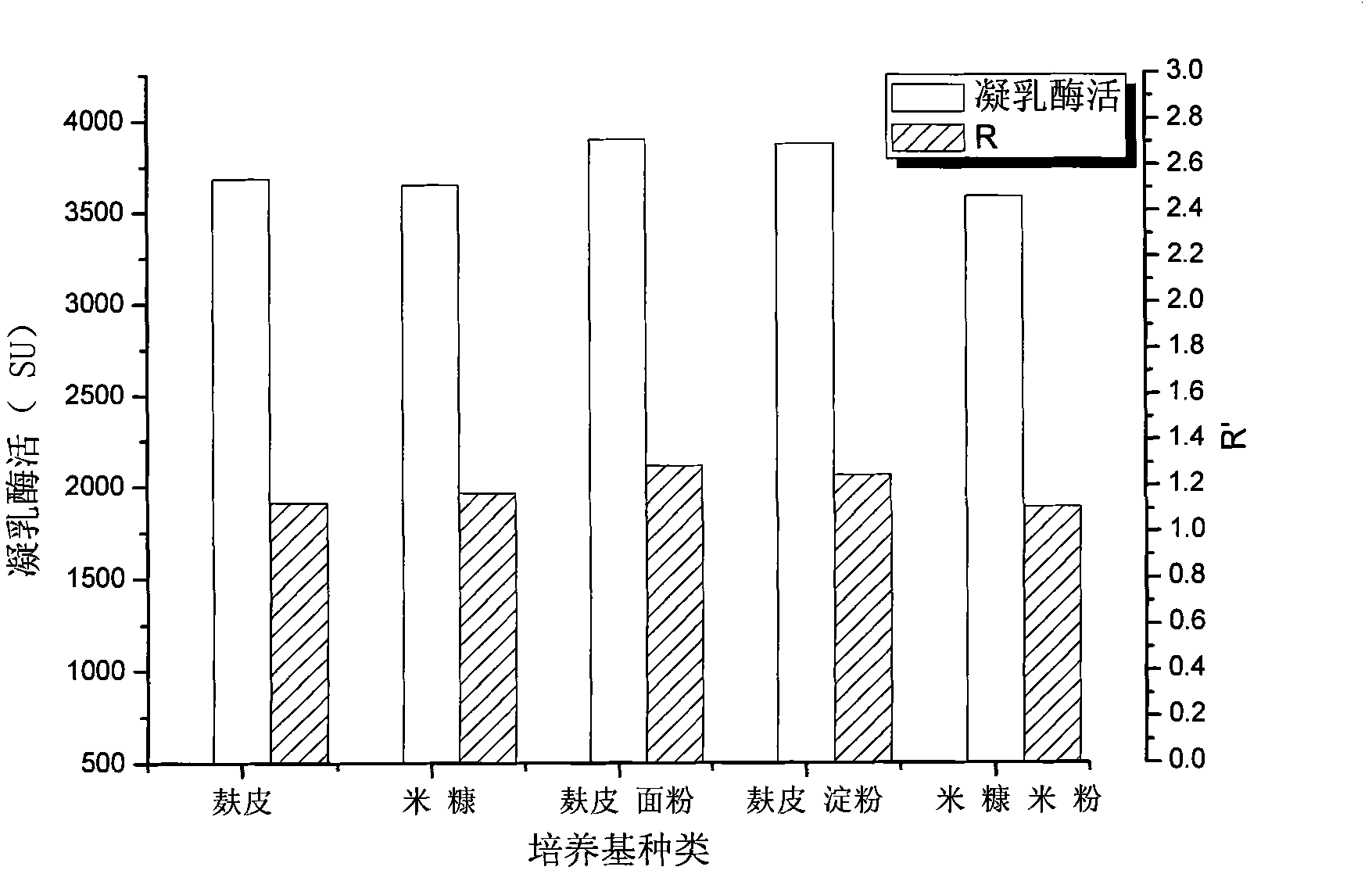

[0024] Several different basal media (bran, rice bran, 9:1 mass ratio of bran and flour compound, bran starch compound, rice bran rice flour compound) are selected as carbon source, and the fermentation process (nitrogen source is degreasing) Milk powder, the quality is 1% of the basic medium; 0.7gMgSO is added to every 100ml of water 4 , 0.9gFeSO 4 And 0.1g proline, and use 0.2N HCl to adjust the pH to 6.5~7.0 as acidic nutrient solution; add 15ml of acidic nutrient solution for every 10g solid; the selection range of fermentation temperature is 35~37℃, and the interval of fermentation time is 72~100 hours) Under the same conditions, mix well and sterilize at 121°C for 30 minutes. After cooling, inoculate with Aspergillus niger strain, and carry out solid fermentation. The fermentation temperature is 35~37°C and the fermentation time is 72~100 hours. Water is used as solvent for solid-liquid After extraction, centrifugation and suction filtration, the supernatant was concentrat...

Embodiment 2

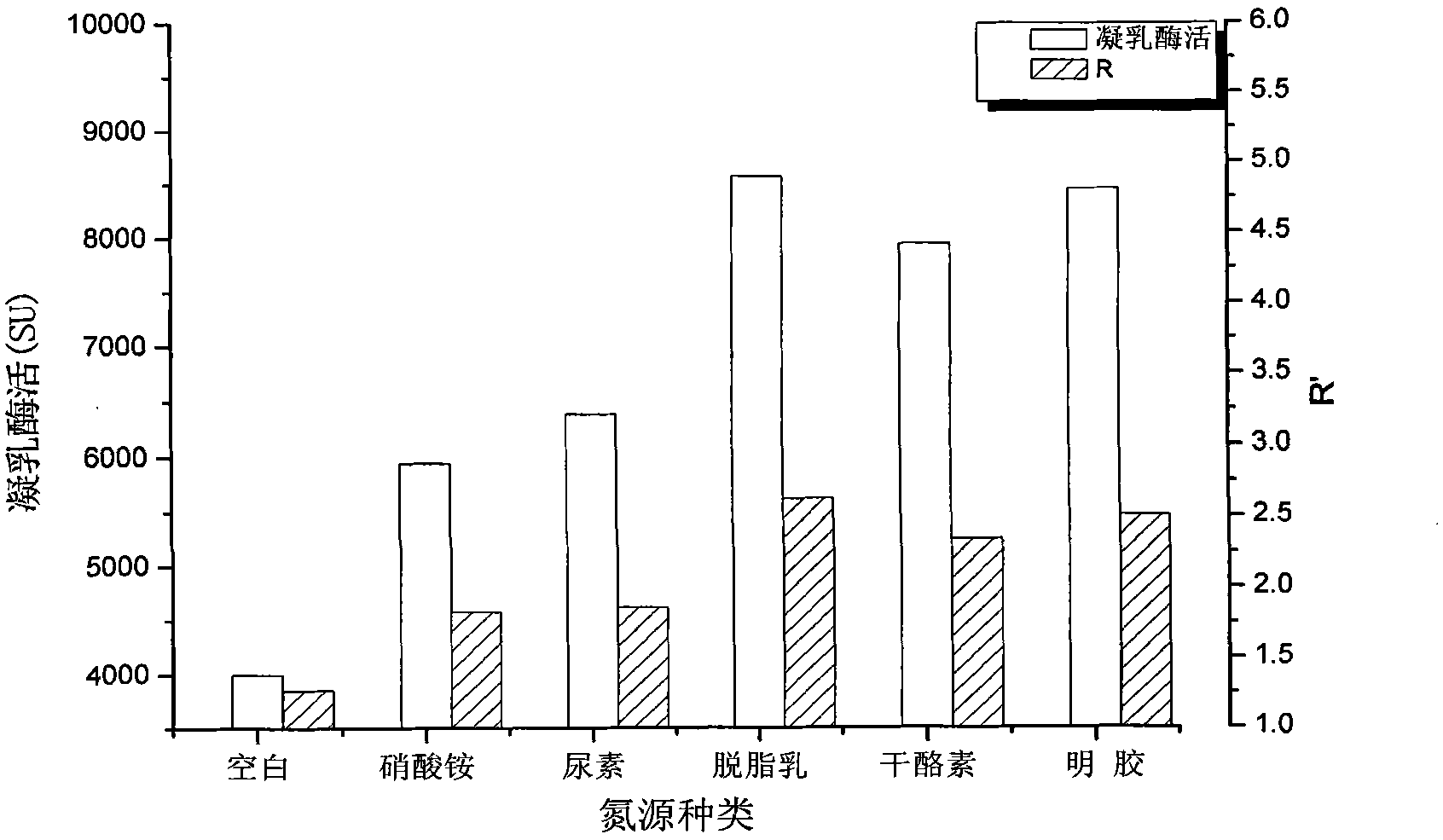

[0026] Using a 9:1 mass ratio of bran flour compound as the basic medium carbon source, different nitrogen sources (ammonium nitrate, urea, skimmed milk powder, casein and gelatin) were selected respectively. The nitrogen source quality accounted for 1% of the solid medium quality. %), in its fermentation process (add 0.7gMgSO per 100ml of water 4 , 0.9gFeSO 4 And 0.1g proline, and adjust the pH to 6.5~7.0 with 0.2N HCl, it is acidic nutrient solution; add 15ml acidic nutrient solution for every 10g solid) under the same conditions, mix and sterilize at 121℃ for 30 minutes, and use Aspergillus niger after cooling. Strains were inoculated and solid fermentation was carried out. The fermentation temperature was 35~37℃, and the fermentation time was 72~100 hours. After solid-liquid extraction with water as solvent, centrifugation and suction filtration, the supernatant was concentrated by vacuum rotary evaporation and freeze-dried , To obtain the coarse dry powder of rennet, the re...

Embodiment 3

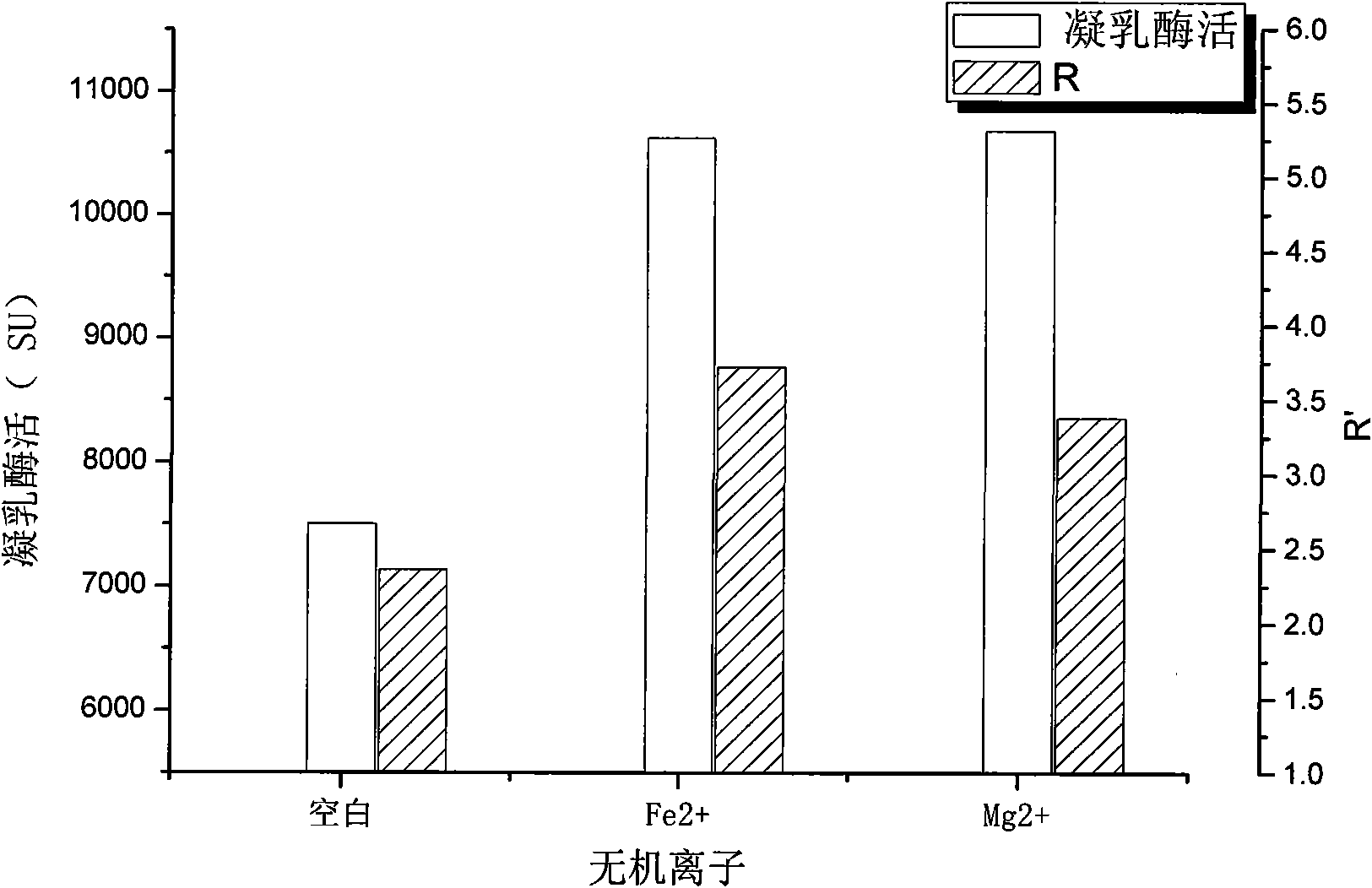

[0028] To a solid medium prepared with a 9:1 mass ratio of bran flour compound as a basic medium carbon source and 1% skimmed milk powder as a nitrogen source, add an acidic nutrient solution containing inorganic salts: each 100ml water is added separately 0.7gFeSO 4 Or 0.9gMgSO 4 , Add 0.1g proline at the same time, adjust the pH to 6.5-7.0 with 0.2N HCl, add 15ml acidic nutrient solution for every 10g solid. Mix and sterilize at 121°C for 30 minutes. After cooling, inoculate with Aspergillus niger strain and carry out solid fermentation. The fermentation temperature is 35~37°C and the fermentation time is 72~100 hours. Water is used for solid-liquid extraction and centrifugation. , After suction filtration, the supernatant was concentrated by vacuum rotary evaporation and lyophilized to obtain a coarse dry powder of rennet. The rennet activity and protease activity in the Aspergillus niger product image 3 . The experimental results show that Fe 2+ Ions and Mg 2+ The presence...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com