A kind of bio-organic fertilizer produced from papermaking sludge and its manufacturing method

A bio-organic fertilizer and papermaking sludge technology, applied in the direction of organic fertilizer, sewage/sludge fertilizer, application, etc., can solve problems such as high moisture content, impact on urban environmental sanitation, complex composition of papermaking sludge, etc., to promote aggregate structure The formation of water and fertilizer retention, the effect of improving and fertilizing the soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

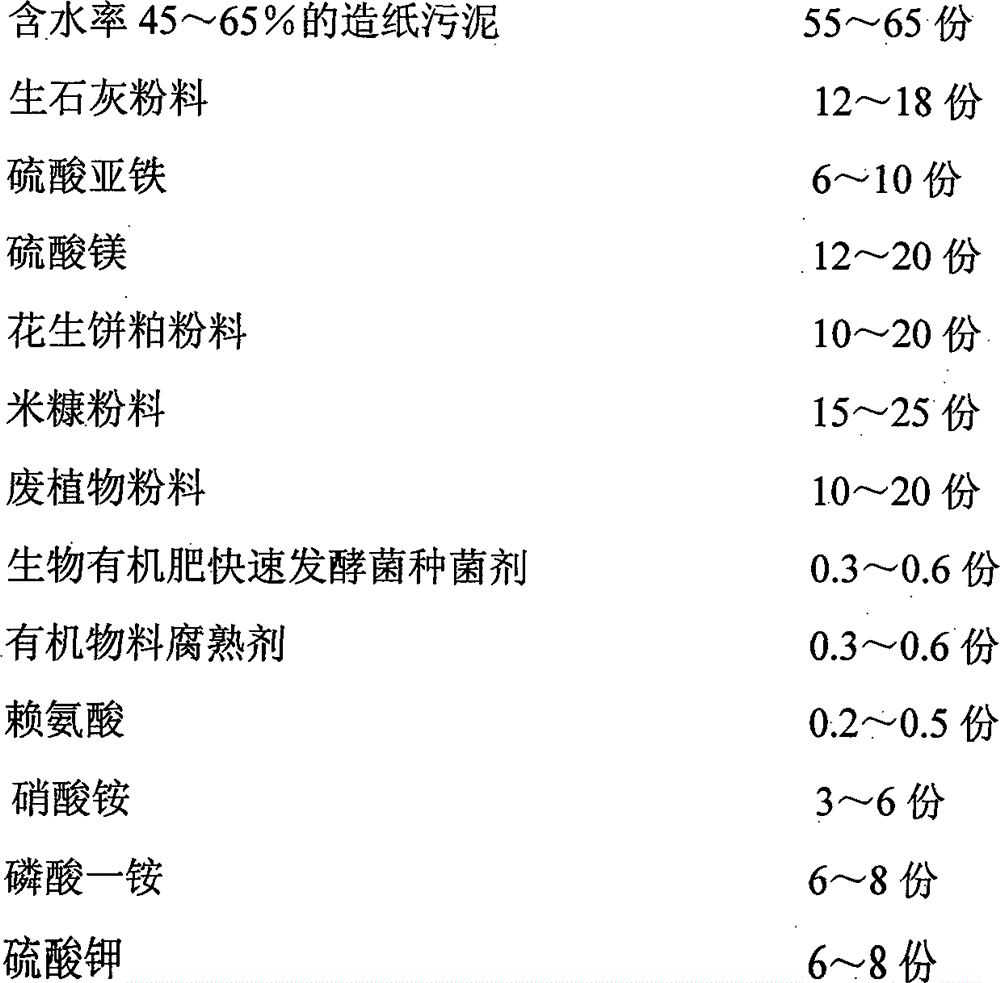

Embodiment 1

[0050] It is a kind of mixed solid waste that is separated from the industrial waste water produced by the paper mill during the production of various papers and the domestic sewage discharged from the living area of the factory, after being treated by the sewage treatment plant, and mechanically dehydrated to a moisture content of 45%. , 50%, 55%, 60%, 65% of paper sludge;

[0051] The shelled peanut pulp is used as the raw material, and the by-product after the oil is extracted by mechanical pressing. After crushing, drying, milling and sieving, peanut cake powder with a particle size of 0.18mm is made for use;

[0052] A kind of rice husk waste separated from rice through mechanical processing, after being crushed, dried, milled, and sieved, it is made into rice bran powder with a particle size of 0.18mm for use;

[0053] The leaves, branches and grass produced by urban landscaping workers during pruning, the waste wood selected during the sorting process of domestic was...

Embodiment 2

[0056] Get the papermaking sludge 65kg with moisture content 50% prepared by Example 1, 18kg of quicklime powder of 0.18mm, ferrous sulfate 10kg, magnesium sulfate 20kg and mix for deodorization, disinfection, drying, crushing, and peanut cake powder 20kg , 25kg of rice bran powder, 20kg of waste plant powder, 0.6kg of bio-organic fertilizer rapid fermentation strain agent, 0.6kg of organic material decomposing agent, and 0.5kg of lysine are mixed evenly and then dynamically carried out high-temperature fermentation with a mechanical container. The fermentation temperature is 80°C, the fermented sludge clinker is dried and sieved to make a mixed powder with a particle size of 0.18mm for use, and then the mixed powder is mixed with 6kg of ammonium nitrate, 8kg of monoammonium phosphate, and potassium sulfate 8kg, triacontanol 0.05kg, sodium nitrophenolate 0.05kg and organic activator 0.6kg are mixed evenly with a biaxial paddle mixing mixer, and are made into bio-organic fertilize...

Embodiment 3

[0058] Get the papermaking sludge 58kg, 0.18mm unslaked lime powder material 13kg, ferrous sulfate 7kg, magnesium sulfate 14kg that embodiment 1 prepares moisture content 55% and mix and carry out deodorization, disinfection, drying, pulverizing, and peanut cake powder material 12kg, 18kg of rice bran powder, 13kg of waste plant powder, 0.4kg of bio-organic fertilizer rapid fermentation strain agent, 0.4kg of organic material decomposing agent, and 0.3kg of lysine are mixed evenly and used in a fermentation tank for high-temperature fermentation. The fermentation temperature is 65°C. The fermented sludge clinker is dried and sieved to make a mixed powder with a particle size of 0.18mm for use, and then the mixed powder is mixed with 4kg of ammonium nitrate, 6.5kg of monoammonium phosphate, and 6.5kg of potassium sulfate. , triacontanol 0.03kg, sodium nitrophenolate 0.03kg and organic activator 0.3kg, mixed evenly with a biaxial paddle mixer to make a bio-organic fertilizer powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com