Preparation method and application of highly ordered ternary titanium-aluminum-tin alloy oxide nano-tube array

A nanotube array and highly ordered technology, applied in the field of material chemistry, can solve the problems of composite photocatalysts that cannot effectively exert their activity, reduce high specific surface area, waste of visible light, etc., achieve strong photocatalytic efficiency and photocatalytic activity, and improve adsorption capacity and photocatalytic efficiency, the effect of increasing the range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

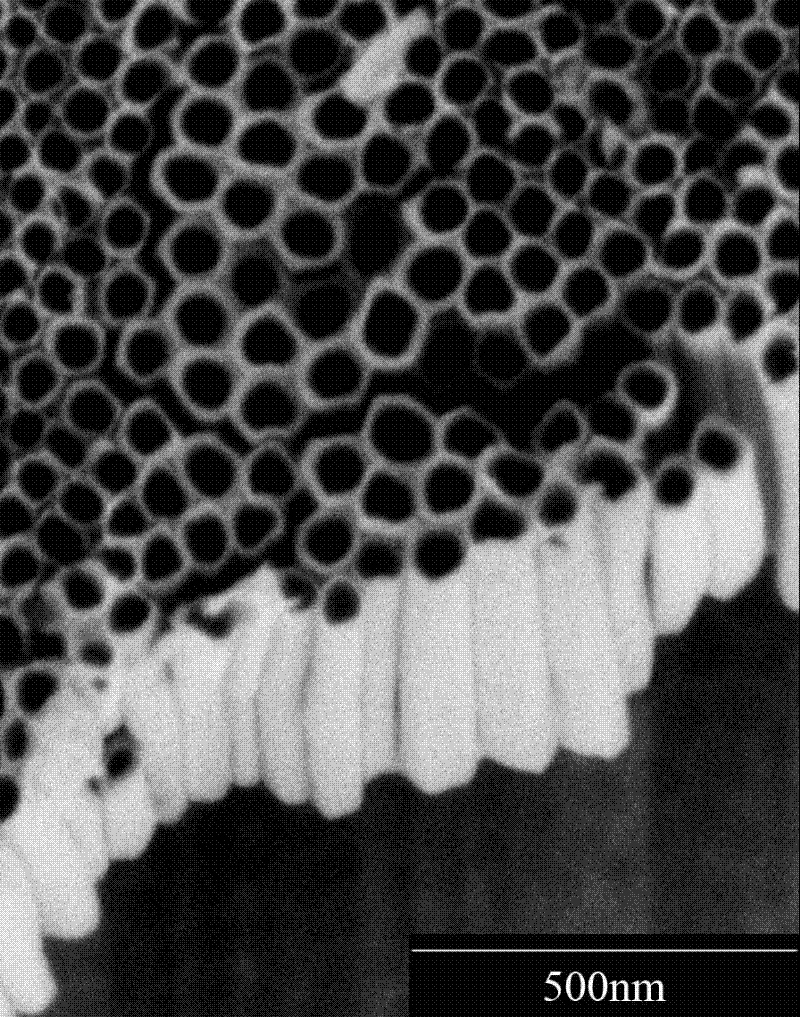

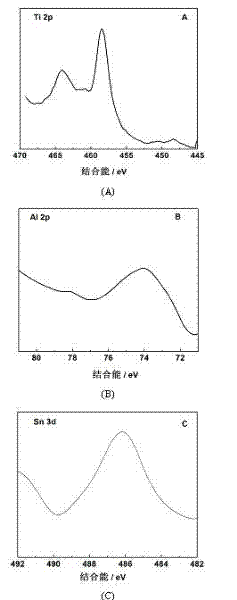

[0024] The preparation process and characterization of titanium-aluminum-tin alloy oxide nanotube array photoanode, the specific steps are as follows:

[0025] Ti-5Al-2.5Sn (gifted by Xi’an Titanium Alloy Research Institute) was cut into 15×50×1 mm samples with a wire cutting machine. After the alloy sheet was polished with 100# and 500# sandpaper in turn, it was polished into a mirror surface with metallographic sandpaper, and then ultrasonically cleaned in distilled water and acetone for 15 minutes each. At room temperature, the pre-treated titanium alloy sheet was used as the anode, and the platinum sheet electrode was used as the counter electrode. / L ammonium fluoride ethylene glycol solution as electrolyte, constant potential +30V anodization for 3 hours, after anodization, take out the sample and clean it with double distilled water, dry it in nitrogen, and then place it in a tube furnace oxygen atmosphere Heat treatment, the temperature was raised from room temperatur...

Embodiment 2

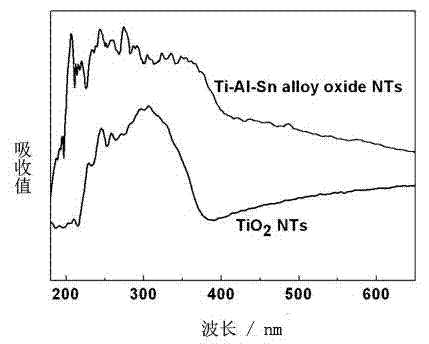

[0030] Using titanium-aluminum-tin alloy oxide nanotube arrays to simulate solar photocatalytic degradation of organic dye wastewater methylene blue, the specific steps are as follows:

[0031] The degradation experiment of methylene blue was carried out in a 100mL single-cell circular quartz glass container, plus a set of cups with circulating water. Using a three-electrode degradation system, TiO 2 The array of NTs and alloy oxide nanotubes is used as the anode, the titanium plate (15×50×1 mm) is used as the cathode, the distance between the two electrodes is 1 cm, and the effective photoanode area is 3 cm 2 . With 0.1 mol / L Na 2 SO 4 Prepare methylene blue to a concentration of 40 mg / L in deionized water - The simulated wastewater was treated with a volume of 60 mL. Using simulated sunlight as the light source, the light intensity is 100 mW / cm 2 . Apply a bias voltage of +0.5 V (relative to the saturated calomel electrode) with a DC stabilized power supply (Shanghai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com