Naphtha adsorbing separation and optimized utilization method

An adsorption separation, naphtha technology, applied in the petroleum industry, refining hydrocarbon oil and other directions, can solve the problems of difficult to improve the utilization rate of bed molecular sieve, low yield, low ethylene yield and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

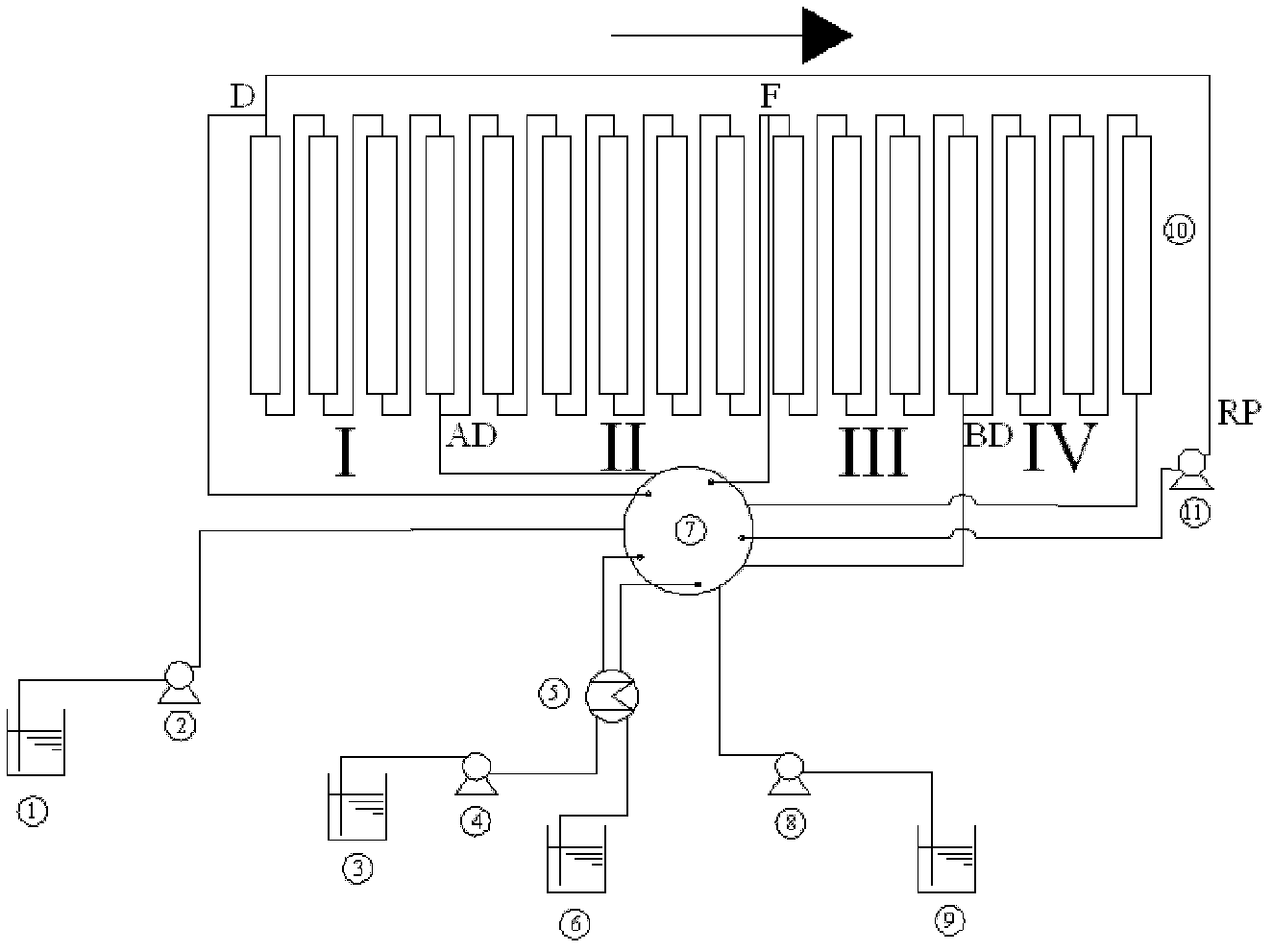

[0064] In the present invention, the naphtha and the desorbent are heated to 150-170° C., and are fed into the raw material inlet (F) and the desorbent inlet (D) of the simulated moving bed filled with 5A molecular sieve respectively. In the adsorption zone (Zone III) of the simulated moving bed, alkanes replace the desorbent adsorbed in the molecular sieve and are adsorbed in the pores of the molecular sieve. °C, the absorbing oil is condensed and liquefied, and then the desolventizing absorbing oil rich in non-normal paraffins is obtained after passing through the desorbent recovery tower, and the weight content of non-normal hydrocarbons in the desolventizing absorbing oil is 90-100%; The desorbent replaces the normal alkanes adsorbed in the molecular sieve in the desorption zone (I zone) of the simulated moving bed and takes it out from the desorption oil outlet (AD), cools to 10-30°C, and the desorption oil is condensed, Liquefaction, and then through the desorbent recove...

Embodiment 1

[0092] see figure 1 The technological process of the present invention, the technological process of the present invention comprises the steps:

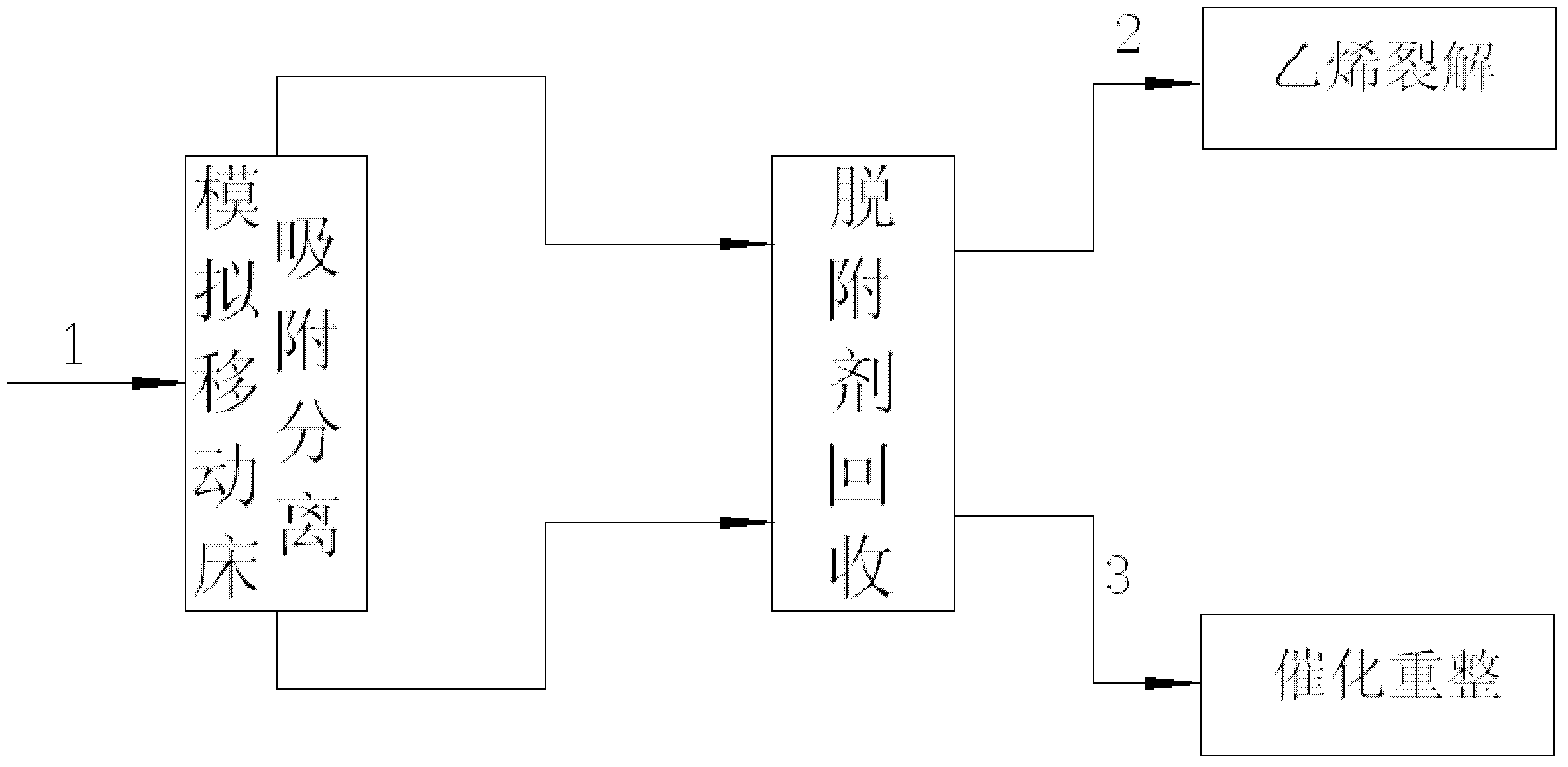

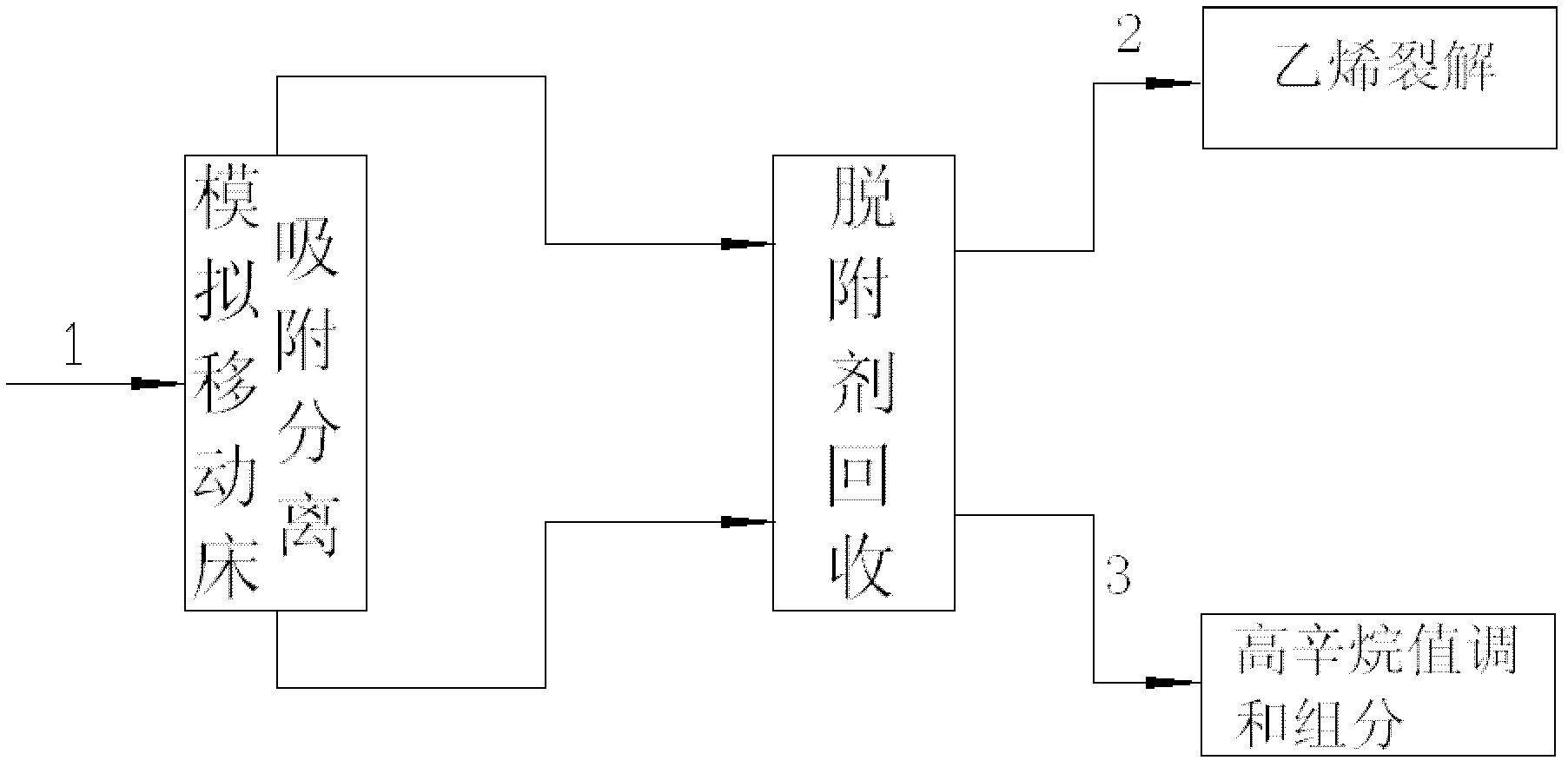

[0093] Pass the liquid naphtha and the desorbent into the separation column III and I respectively filled with 5A molecular sieves, and the n-alkanes in the naphtha are adsorbed in the micropores of the bed molecular sieves in the I zone, and the adsorbed Absorption oil flows out of the simulated moving bed separation column III area, cooled, and the absorption oil is condensed to obtain the absorption oil rich in non-normal paraffins, which is sent to the catalytic reforming unit 3 to obtain reformed products such as benzene, toluene and Xylene;

[0094] At the same time, the desorbent desorbs in zone I of the simulated moving bed separation column, and the desorbent carrying normal paraffins flows out of zone I of the simulated moving bed separation column, and the normal paraffins are condensed and liquefied to obtain normal hydr...

Embodiment 2

[0103] Process flow of the present invention such as figure 1 shown.

[0104] 5kg of straight-run liquid naphtha with a distillation range of 40-180°C containing normal paraffins with a mass concentration of 30% passes through a simulated moving bed molecular sieve bed at a temperature of 150°C, and 3.4kg of 5A molecular sieves are filled in the bed, and the bed height is is 30cm, the aspect ratio is 10:1, and the naphtha feed space velocity is 0.17h -1 , the desorbent n-pentane feed space velocity is 0.68h -1 , the switching time is 900 seconds, and the absorption intermediate oil and desorbed oil are obtained after condensation, and the mass concentration of non-normal alkanes in the desolvation and absorption intermediate oil obtained after the absorption intermediate oil and desorbed oil are recovered through the desorbent agent The mass concentration of n-alkanes in the desolvated and desorbed oil obtained was 95%.

[0105] The desolvation and absorption intermediate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com