Ecological water-retaining agent used for restoring saline lands, and preparation method thereof

A technology of water-retaining agent and saline-alkali land, applied in the direction of chemical instruments and methods, applications, organic fertilizers, etc., can solve the problems of low gel strength, poor salt resistance of water-retaining agent, short service life, etc., to improve grafting reaction speed, water retention The effect of low agent cost and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

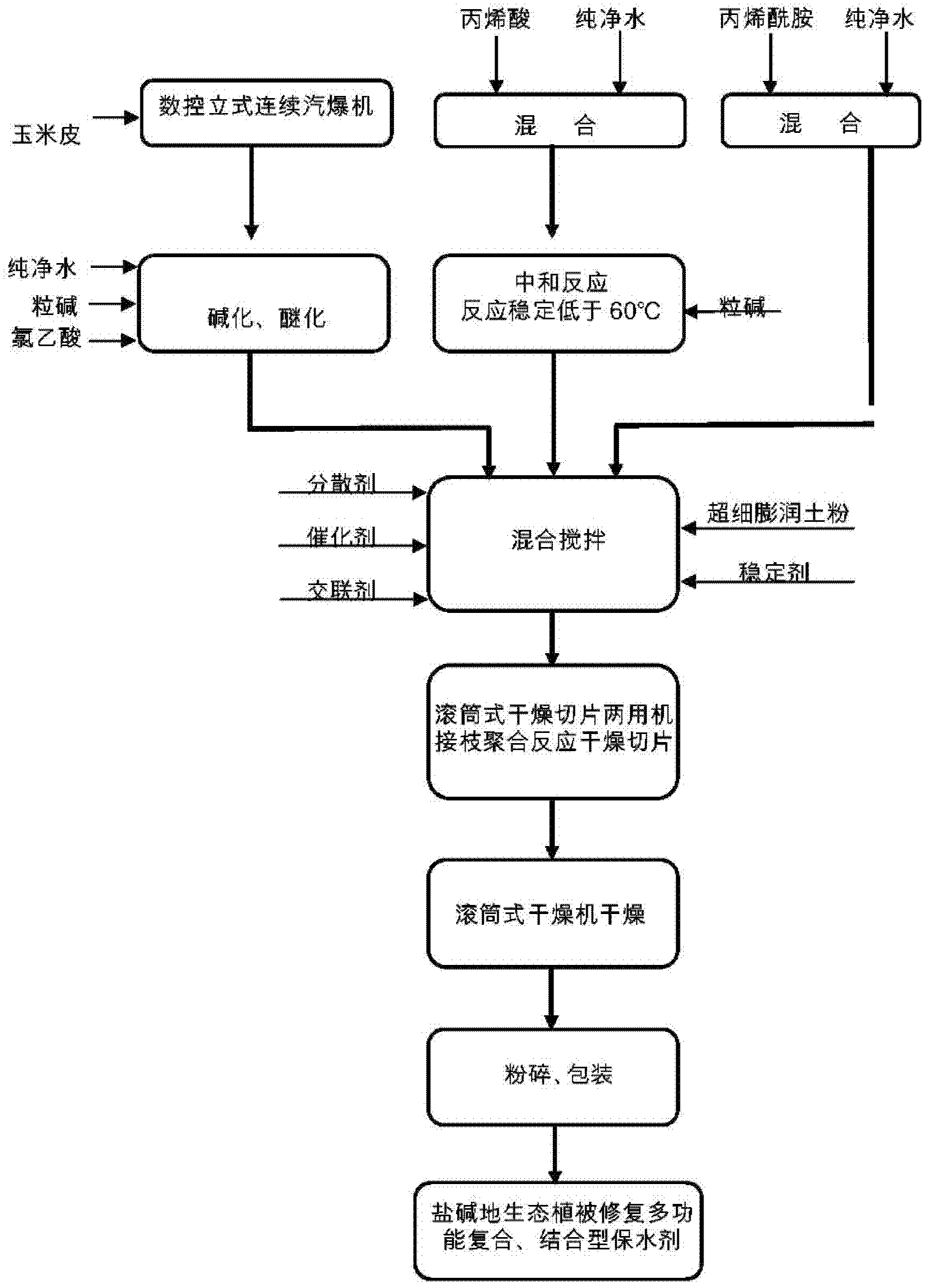

Method used

Image

Examples

Embodiment 1

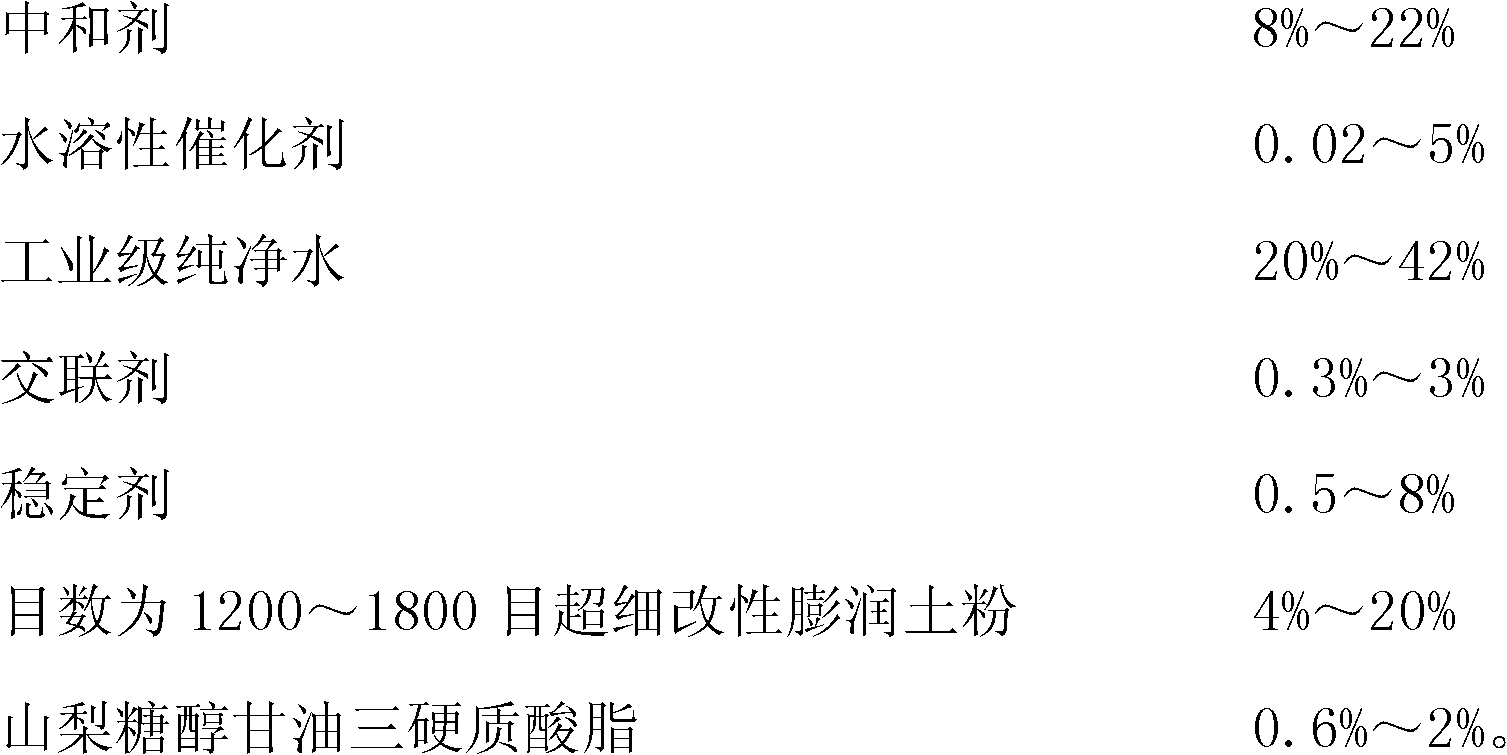

[0040] Embodiment 1: A water-retaining agent for restoring saline-alkali ecology, said water-retaining agent is composed of the following parts by weight:

[0041]

[0042]

[0043] The water-soluble catalyst is potassium persulfate or hydrogen peroxide or ammonium persulfate. The cross-linking agent is glycerol or epichlorohydrin or N,N-methylenebisacrylamide. The stabilizer is polyethylene glycol or polypropylene oxide or polyoxyethylene nonphenyl ether. The molecular formula of the technical grade acrylic acid is CH 2 =CHCOOH, the content of acrylic acid is greater than 99%. The molecular formula of industrial grade acrylamide is: CH 2 =CHCONH 2 , the content of acrylamide is greater than 98%. The neutralizing agent refers to the industrial ionic membrane method granular alkali with a content greater than 99%. The industrial-grade purified water has no calcium and magnesium ions.

[0044] The preparation steps of described modified corn bran are:

[0045] 1) F...

Embodiment 2-10

[0049] Embodiment 2-10: the same as embodiment 1, the difference is that the water-retaining agent is composed of substances according to the parts by weight in the following table:

[0050]

Embodiment 11

[0051] Embodiment 11: the same as embodiment 1, the difference is:

[0052] The preparation steps of described modified corn bran are:

[0053] 1) Firstly, corn husks are steam-exploded using a continuous steam explosion machine, and the steam explosion conditions are as follows: the density of the corn husks is 140Kg / m3, the holding time is 60S, and the pressure is 0.8-0.9MPa.

[0054] 2) Add the corn bran after step 1) in the reaction kettle, add water and adjust to a slurry with a corn bran content of 15%, then slowly add 25% sodium hydroxide solution for alkalization, at this time, the corn bran and The mass ratio of sodium hydroxide is 1:0.6;

[0055] 3) Stir at 35-45°C for 20 minutes and then add chloroacetic acid for etherification. At this time, the mass ratio of corn bran to chloroacetic acid is 1:0.6;

[0056] 4) Raise the temperature to 60° C. while maintaining constant temperature and stirring for 60 minutes, wash with ethanol, dry and pulverize after washing to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com