Method for preparing palladium nanometer sheet with optical property

A palladium nano and flake technology, applied in the field of preparation of palladium nano materials, can solve the problems such as difficult control of the formation and growth of nano crystal nuclei on the surface of the substrate, uncontrollable particle size of nano gold, cumbersome product purification process, etc. Large-scale production, easy operation and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Add 20mL water and 4mL ethanol in turn to the reaction vessel, and stir to obtain a water-ethanol mixed solution system;

[0042] 2. Set the final concentration to 7.04×10 -4mol / L of PdCl 2 Powder and 1.49×10 -2 Add mol / L CTAB to the water-ethanol mixed solution system, put the prepared solution on a constant temperature magnetic stirrer at 25°C and stir for 2 hours, the color of the solution is light yellow;

[0043] 3. Put the uniformly stirred reaction solution in a self-designed light reaction box, and place it under a 60W ordinary commercially available incandescent light for 6 hours in parallel;

[0044] 4. The obtained black precipitate was separated by centrifugation, washed once with ethanol and acetone, and dried in a vacuum oven at 40° C. for 24 hours to obtain a palladium nanosheet material.

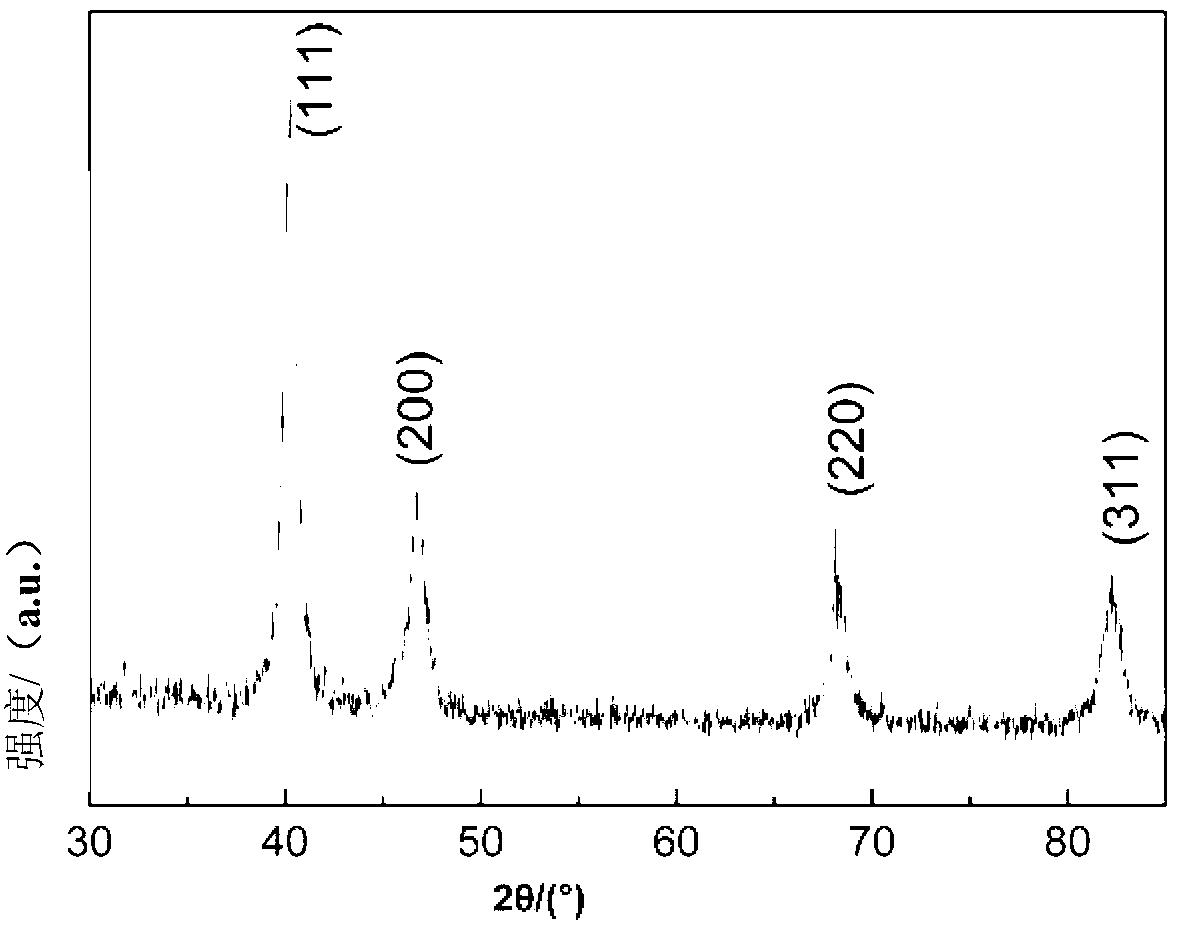

[0045] 5. The X-ray diffraction (XRD) pattern of the sample is measured by Beijing Puxi General Instrument Co., Ltd. XD-3 X-ray diffraction analyzer (Cu target, ...

Embodiment 2

[0048] 1. Add 20mL water and 4mL ethanol in turn to the reaction vessel, and stir to obtain a water-ethanol mixed solution system;

[0049] 2. Set the final concentration to 7.04×10 -4 mol / L of PdCl 2 Powder and 7.04×10 -4 Add mol / L CTAB to the water-ethanol mixed solution system, put the prepared solution on a constant temperature magnetic stirrer at 25°C and stir for 2 hours, the color of the solution is light yellow;

[0050] 3. Put the evenly stirred reaction solution in a self-designed light reaction box, and place it under a 60W incandescent light for 6 hours in parallel;

[0051] 4. The obtained black precipitate was separated by centrifugation, washed once with ethanol and acetone, and dried in a vacuum oven at 40° C. for 24 hours to obtain a palladium nanosheet material.

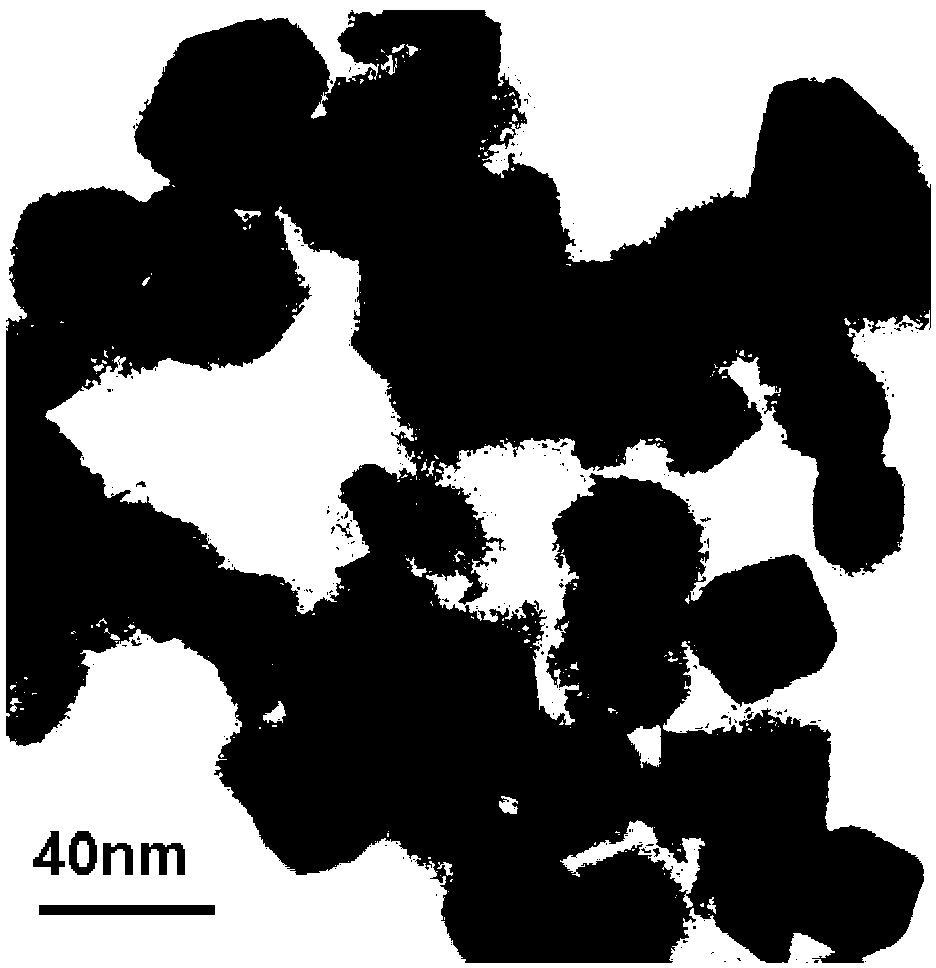

[0052] 5. The microscopic morphology of the nano-palladium flake material is as follows: image 3 As shown, the morphology of palladium nanoflakes is mostly hexagonal, the particle size distribu...

Embodiment 3

[0054] 1. Add 20mL water and 4mL ethanol in turn to the reaction vessel, and stir to obtain a water-ethanol mixed solution system;

[0055] 2. Set the final concentration to 7.04×10 -4 mol / L of PdCl 2 Powder and 5.64×10 -2 Add mol / L CTAB to the water-ethanol mixed solution system, put the prepared solution on a constant temperature magnetic stirrer at 25°C and stir for 2 hours, the color of the solution is light yellow;

[0056] 3. Put the uniformly stirred reaction solution in a self-designed light reaction box, and place it under a 60W ordinary commercially available incandescent light for 6 hours in parallel;

[0057] 4. The obtained black precipitate was separated by centrifugation, washed once with ethanol and acetone, and dried in a vacuum oven at 40° C. for 24 hours to obtain a palladium nanosheet material.

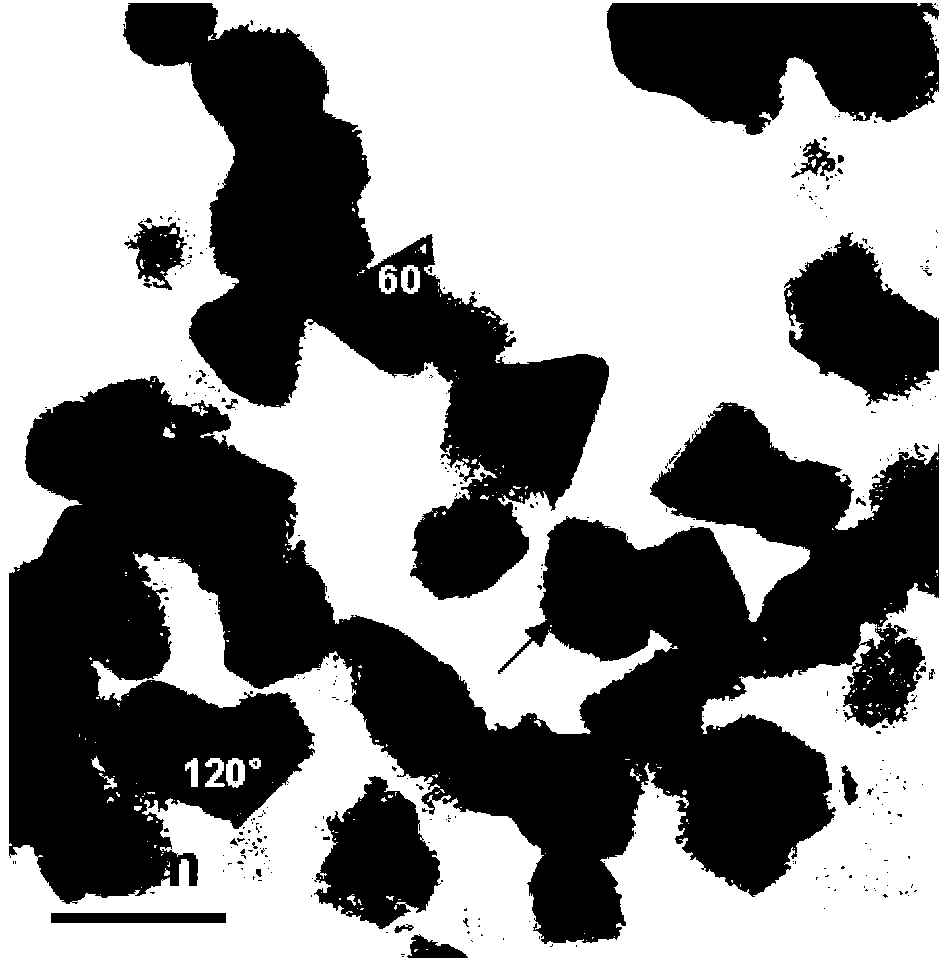

[0058] 5. The microscopic morphology of nano-palladium materials is as follows: Figure 4 As shown, the morphology of palladium nanoflakes is triangle, rhombus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com