Organic/inorganic composite nanofiber membrane of lithium ion power battery and preparation method of organic/inorganic composite nanofiber membrane

A nanofiber membrane and power battery technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of low fiber bonding strength, difficulty in large-scale production, uneven thickness, etc., and achieve fine fiber diameter and controllability. Strong, high porosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Prepare a PVDF solution with a mass percentage concentration of 40%, add nano-alumina powder with a mass content of 2% to it, the particle size is less than 50nm, mechanically mix and ultrasonically disperse for 30 minutes;

[0025] (2) Using printing paper as the collection carrier, spinning was carried out using an electrospinning machine with flat roller electrodes, the electric field strength was 0.3 kV / mm, the ambient temperature was 20 °C, and the moving speed of the collection carrier was 0.15 m / min.

[0026] (3) After the spinning is completed, the peripheral burrs are cut to obtain the alumina composite PVDF nanofiber membrane material.

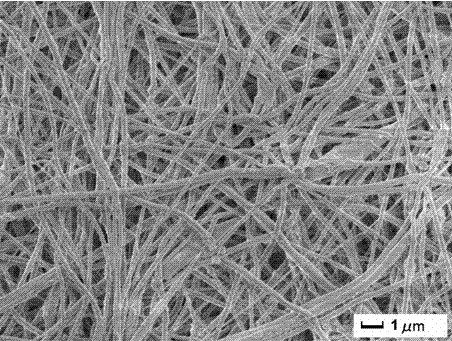

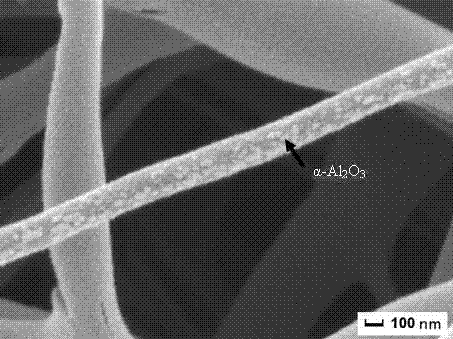

[0027] The macroscopic morphology of the composite fiber membrane, see figure 1 , the mass content of alumina accounts for 2% of the organic components, and it is evenly distributed in the organic polymer fiber to form a skeleton, see image 3 , the diameter of the composite fiber is 170nm±20%, and the surface density of...

Embodiment 2

[0029](1) Prepare a PI solution with a mass percentage concentration of 20%, add nano-titanium oxide powder with a mass content of 10% to it, the particle size is less than 30nm, and emulsify at high speed for 60 minutes.

[0030] (2) Polypropylene spunbonded non-woven fabric is used as the collection carrier, and the spinning is carried out by an electrospinning machine with a flat roller electrode. The electric field strength is 0.6 kV / mm, the ambient temperature is 30°C, and the moving speed of the collection carrier is 0.5m / min .

[0031] (3) After the spinning is completed, the peripheral burrs are cut to obtain the titanium oxide composite PI organic polymer nanofiber membrane material.

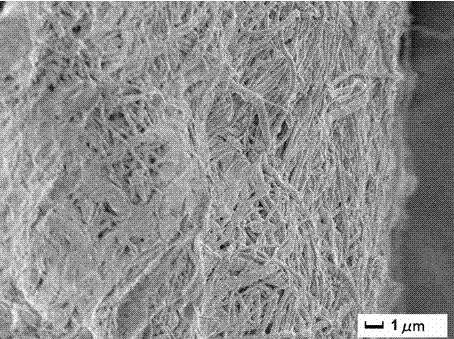

[0032] The mass content of nano-titanium oxide powder accounts for 10% of the organic components, and is evenly distributed in the organic polymer fiber body to form a skeleton. The diameter of the composite fiber is 80nm±30%, and the surface density of the fiber film is 8.12g / m 2 , th...

Embodiment 3

[0034] (1) Prepare a PET solution with a concentration of 30% by mass, add 25% nano zirconium nitride inorganic powder to it, the particle size is less than 50nm, and mechanically ball mill for 50 minutes.

[0035] (2) Using an alumina ceramic plate as a collection carrier, spin by using an electrospinning machine with a flat roller electrode, the electric field strength is 0.5 kV / mm, the ambient temperature is 40°C, and the moving speed of the collection carrier is 1m / min.

[0036] (3) After the spinning is completed, the peripheral burrs are cut to obtain the zirconium nitride composite PET organic polymer nanofiber membrane material.

[0037] The mass content of nano-inorganic powder accounts for 25% of the organic components, and is evenly distributed in the organic polymer fiber body to form a skeleton. The diameter of the composite fiber is 124nm±20%, and the surface density of the fiber film is 9.98 g / m 2 , the thickness is 27±1um, the air permeability is 22 L / m 2 / s....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Air permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com