Strain for producing organic solvent tolerant lipase, organic solvent tolerant lipase and preparation method of organic solvent tolerant lipase

A technology of lipase and strain, applied in biological field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Example 1: Isolation, screening and identification of lipase-producing filamentous fungus Cladosporium sp.WBRD3.10062425

[0072] Take a piece of Tibetan ghee sample as fresh as possible, remove about 1cm thick surface layer, cut about 10g of Tibetan ghee sample and place it in 100mL sterile water containing 1.0% Tween 80. After shaking for 30 minutes, it was diluted to different dilutions according to the traditional dilution coating method, and the samples of each dilution were coated on Rhodamine B plates and placed in a 28°C biochemical incubator for cultivation.

[0073] The making method of the plate of rhodamine B is: formula A solution (ammonium sulfate 0.1%, yeast extract juice 0.5%, tryptone 0.5%, K 2 HPO 4 0.1%, KCl 0.5%, magnesium sulfate heptahydrate 0.05%, ferrous sulfate heptahydrate 0.01%, agar 2.0%) sterilized at 115°C for 30min, and then added formula B solution sterilized in the same way (olive oil and 2% polyvinyl alcohol Mix at a ratio of 1:3, sti...

Embodiment 2

[0081] Embodiment 2: Preparation of organic solvent-resistant lipase derived from Cladosporium

[0082] (1) Fermentation of Cladosporium lipase

[0083] Add about 10 mL of sterile normal saline to a freshly cultured Cladosporium WBRD3.10062425 slant to prepare a spore suspension, and then take 1 mL of the suspension and inoculate it into a 250-mL seed medium with a volume of 30 mL. Cultivate at 28°C and 200rpm for 24h (medium composition: 3% glucose, 0.3% peptone, 0.5% corn flour, NaH 2 PO 4 12H 2 O 0.2%, MgSO 4 12H 2 O 0.1%, CaCl 2 0.05%, pH 6.5).

[0084] After the seeds have been cultured, 3 mL of the seed culture solution is inoculated into multiple 250 mL volume fermentation shake flasks, and the amount of liquid in the shake flasks is 30 mL. The composition of the fermentation medium is: 2% sucrose, 3% peptone, 0.5% corn flour, 1% yeast extract powder, 0.5% Tween-800.5%, 0.1% talcum powder, NaNO 3 0.3%, KH 2 PO 4 0.7%, Na 2 HPO 4 12H 2 O 0.25%, MgSO 4 12H ...

Embodiment 3

[0093] Example 3: Enzymatic Properties of Cladosporium Lipase

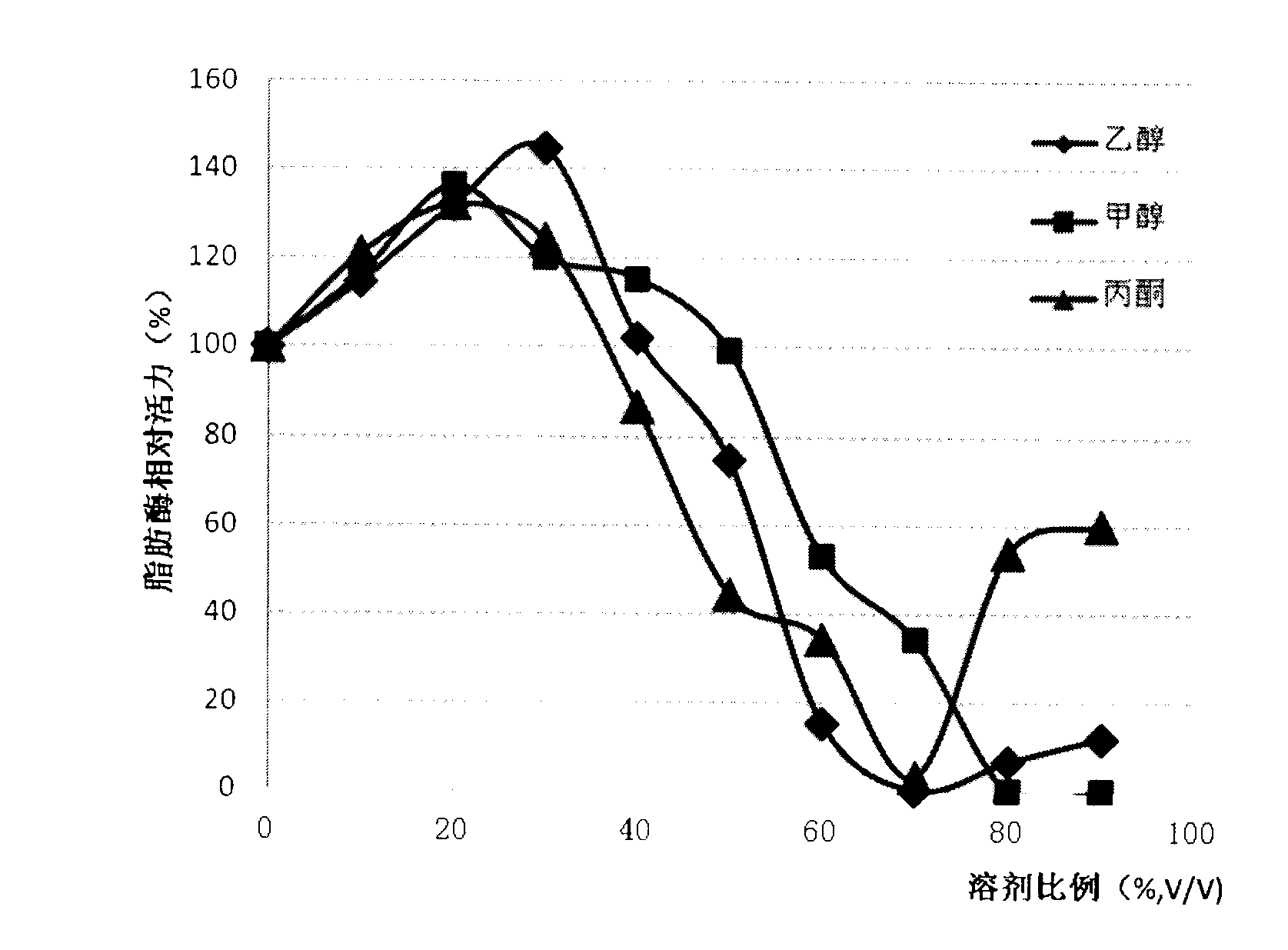

[0094] (1) Investigation of the tolerance of lipase to organic solvents such as methanol

[0095] The Cladosporium lipase purified in Example 2 is mixed with organic solvents such as methanol and ethanol according to a certain ratio (0-90%, v / v), and the lipase is detected by the pNPP method after being placed at 4°C for 24h The size of the activity is compared with the sample without organic solvent, the results are shown in figure 2 . Cladosporium lipase has strong tolerance to methanol, ethanol and acetone, especially to methanol, and there is almost no loss of activity after 24h treatment with 50% methanol.

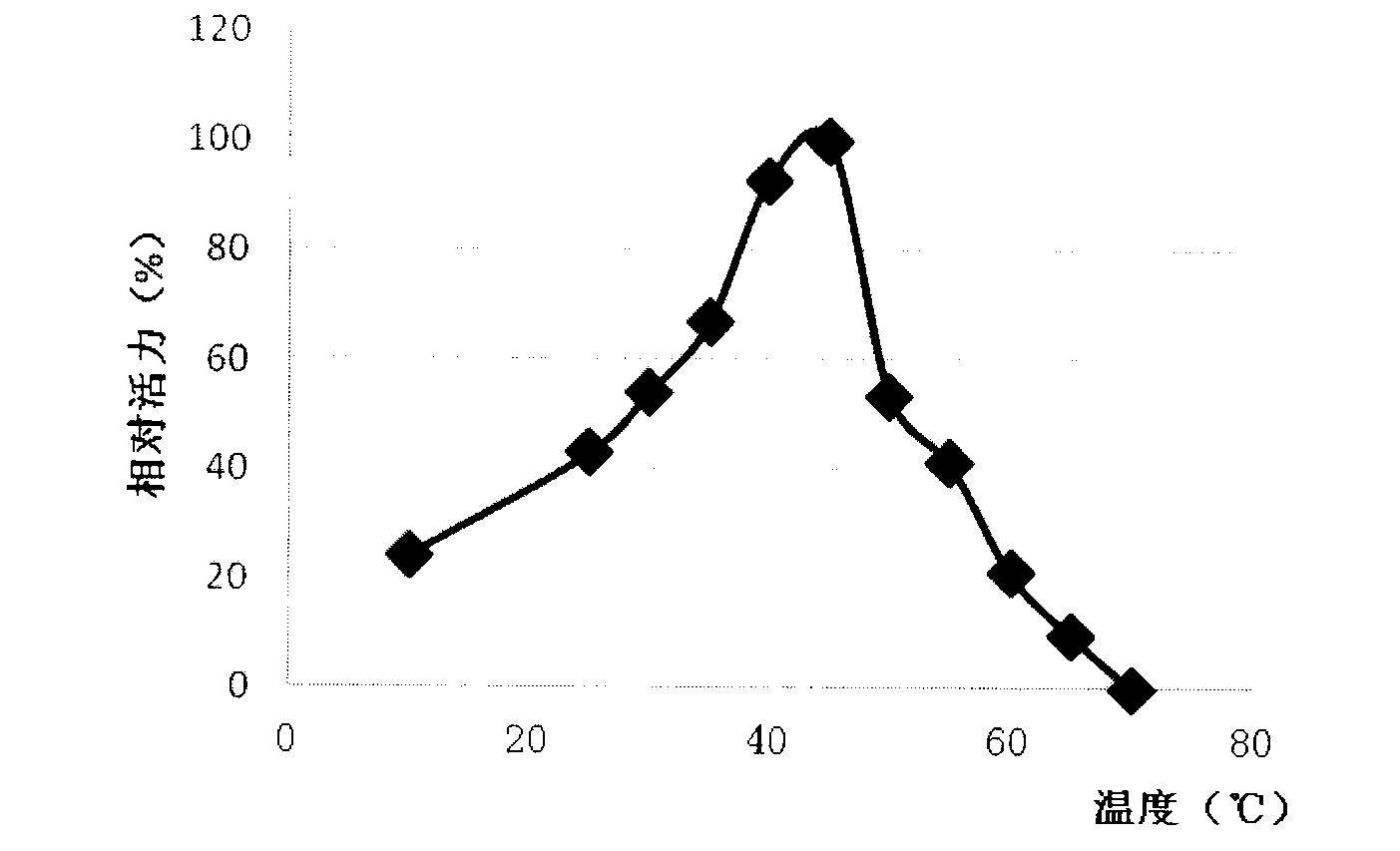

[0096] (2) Determination of temperature-enzyme activity relationship curve and thermal stability curve of lipase:

[0097] In a series of water baths at different temperatures, the activity of Cladosporium lipase was detected by the pNPP method. The results of the enzyme action temperature curve are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com