Oxygen plasma irradiation preparation method of ordered porous array of oxide micro-nano structure

A technology of micro-nano structure and oxygen plasma, which is applied in the field of ion plasma irradiation preparation, can solve the problems of affecting conductivity and device stability, large film on the substrate, unfavorable gas-sensing parameters, etc., and achieves easy operation and uniform thickness , the effect of expanding the application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Synthesis of Monolayer 2D Colloidal Crystal Templates:

[0029] (1) Ultrasonic cleaning of ordinary glass in acetone, ethanol, and deionized water for 30-40 minutes respectively, and drying with N2 gas, and cleaning with ozone ultraviolet for 30 minutes to obtain a super-hydrophilic glass surface;

[0030](2) Place the cleaned ordinary glass on a horizontal experimental workbench, take deionized water and evenly drop it on the glass to form a water film with a thickness of 0.2mm; put polystyrene microspheres with a mass percentage of 2.5% The suspension is dispersed in the same volume of ethanol, and the mixed solution is obtained after the dispersion is uniform; the mixed solution is slowly injected along the corner of the glass covered with deionized water film until the self-assembly of PS microspheres on the air / liquid interface is completed; control Ambient temperature to 30-40° C. is supplemented with weak air flow for drying to obtain a single-layer two-dimension...

Embodiment 2

[0034] A colloidal crystal template composed of polystyrene microspheres with a diameter of 500nm was prepared according to the method of Example 1;

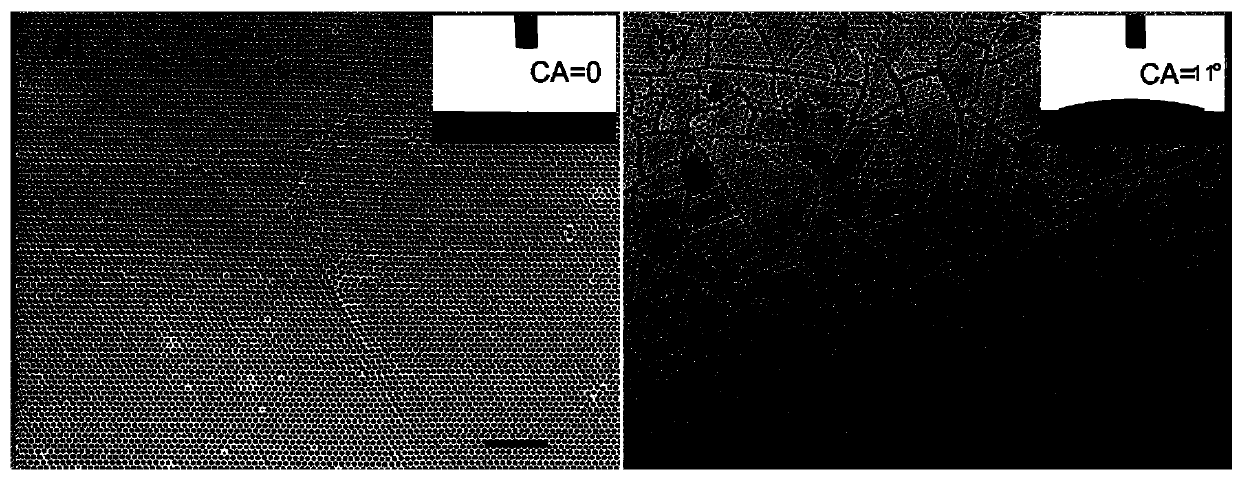

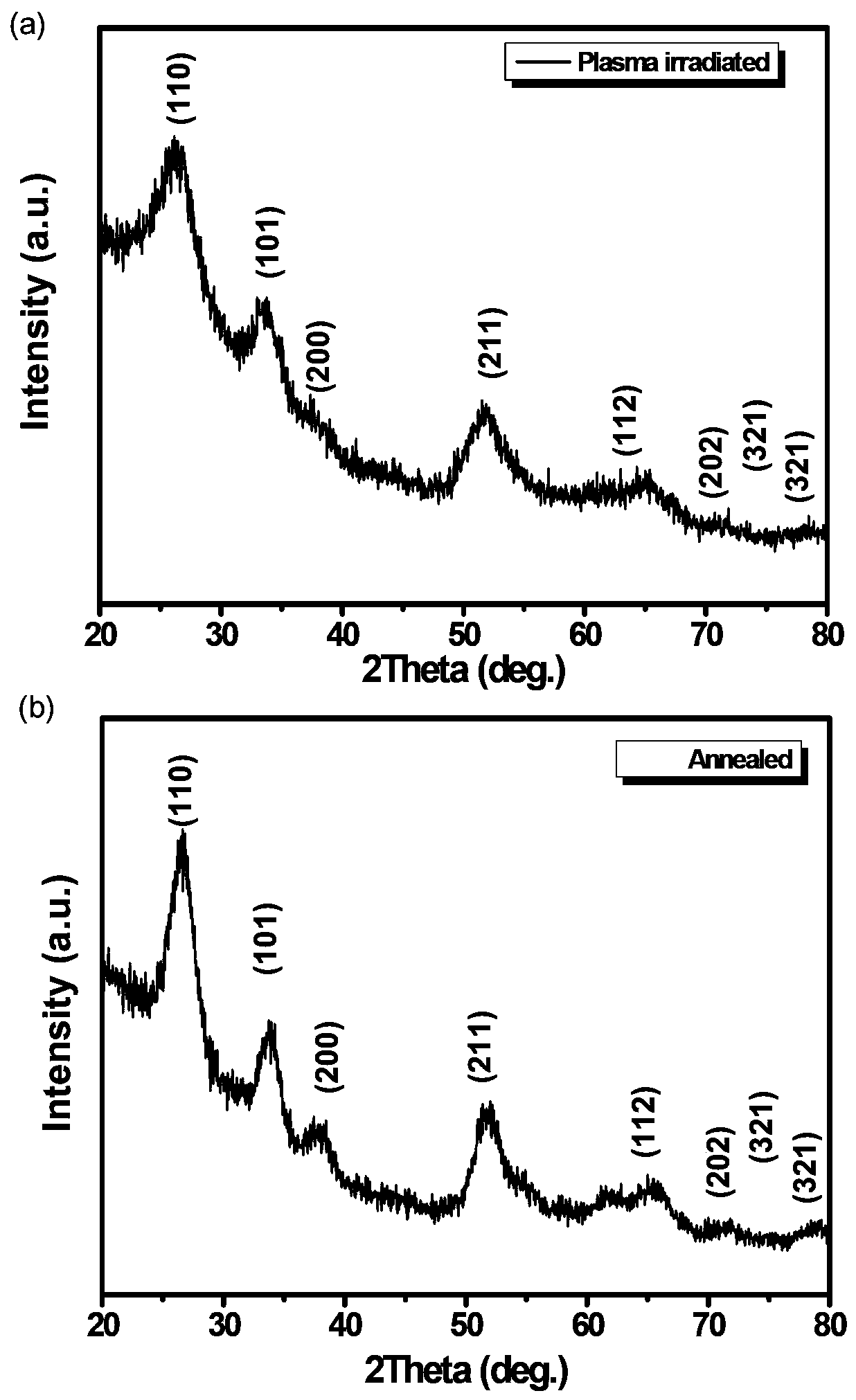

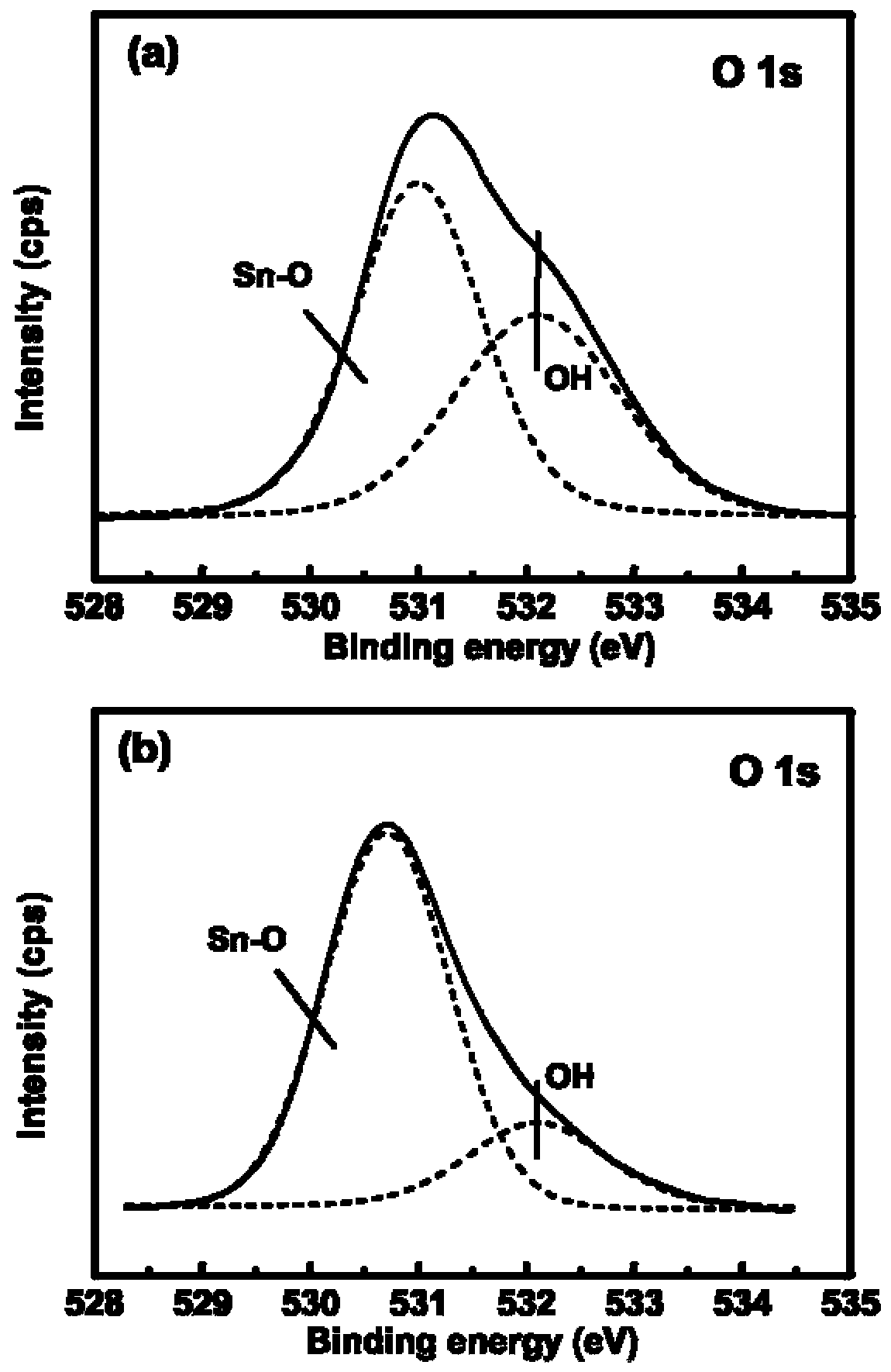

[0035] Transfer and float the colloidal crystal template to the surface of the metal oxide precursor 0.05M tin tetrachloride solution, pick up the template soaked in the solution with a single crystal silicon wafer, place it flat for 5 minutes, and then dry it at 100°C 15 minutes; Then place the dried sample in an oxygen atmosphere in a plasma cleaning machine for 40 minutes of irradiation, the power is 10W, and the oxygen flow is 30sccm, to obtain the following: figure 1 The single-layer crack-free ordered hole array film shown in a. Compared with the method obtained by the annealing method, the film synthesized by this method is uniform and crack-free, and has better surface superhydrophilicity. By X-ray diffraction analysis, the phase of the film synthesized by the inventive method is tin dioxide of rutile phase, such as f...

Embodiment 3

[0037] A colloidal crystal template composed of polystyrene microspheres with a diameter of 1000nm was prepared according to the method of Example 1;

[0038] Transfer and float the colloidal crystal template to the surface of the metal oxide precursor 0.1M tin tetrachloride solution, pick up the template soaked in the solution with a single crystal silicon wafer and place it flat for 5 minutes, then place it in 110°C for drying 20 minutes; Then place the dried sample in an oxygen atmosphere in a plasma cleaning machine for 50 minutes of irradiation, the power is 18W, and the oxygen flow is 50sccm, to obtain the following: Figure 4 The shown single-layer crack-free ordered hole array film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com