A preparation method for porous graphene and a preparation method for a graphene-based aluminium-air cell

A technology of porous graphene and air electrodes, which is applied to fuel cell type half cells and primary cell type half cells, battery electrodes, chemical instruments and methods, etc., to achieve the effects of simple preparation method, reduced production cost and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

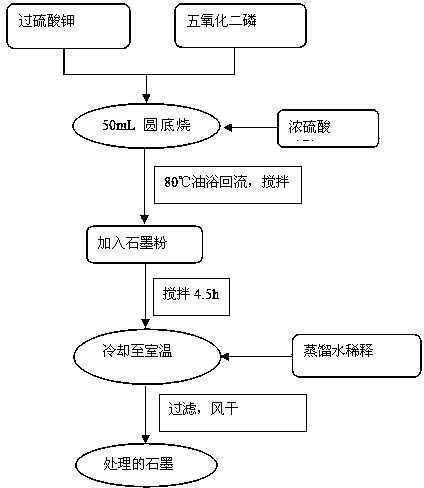

[0057] Embodiment 1: In this embodiment, graphite oxide is prepared by the improved hummers method. Study the experimental method for preparing GO, and optimize its individual process and process steps. The experimental flow charts for pretreatment of graphite and preparation of GO are shown in 1 and 2. The specific experimental steps are as follows:

[0058] (1) Add 12mL of concentrated sulfuric acid to a 50mL round bottom flask, weigh 2.5g each of potassium persulfate and phosphorus pentoxide with an electronic balance, quickly add them to the flask, stir and reflux in an oil bath at 80°C.

[0059] (2) After it dissolves, slowly add 3g of graphite powder to the mixture, and continue to stir and heat at a constant speed for 4.5 hours. into a 1L beaker, slowly add 500mL of water to dilute, and place it in a fume hood overnight.

[0060] (3) After the mixture is clearly stratified, pour off the supernatant, filter it with a Buchner funnel, and wash it with a large amount of di...

specific Embodiment approach 2

[0066] Embodiment 2: The main function of the catalytic layer is to catalyze the reduction reaction of oxygen in the air. In this embodiment, the preparation process of the air electrode is made by manual coating method, and the specific process is as follows:

[0067] Weigh 30 mg of graphene catalyst and place it in a small beaker, add 0.2 g of n-2 methylpyrrolidone (NMP), after ultrasonic dispersion treatment for 30 min, add 0.1 g of polyvinylidene fluoride (PVDF) therein, and stir with a magnetic stirrer 12h, until the catalyst is prepared into a paste and spread evenly on one side of the diffusion layer, prepare two air electrodes, and mark the catalytic layer, then put it in a vacuum oven at 45°C for 12 hours, then cool down and take it out , use a tablet press at 4MPa, press for 5 minutes, and press the electrode sheet tightly to obtain the working electrode.

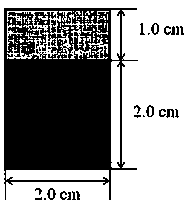

[0068] A 1.0cm nickel foam current collector is left on the upper side of the air electrode, mainly for the co...

specific Embodiment approach 3

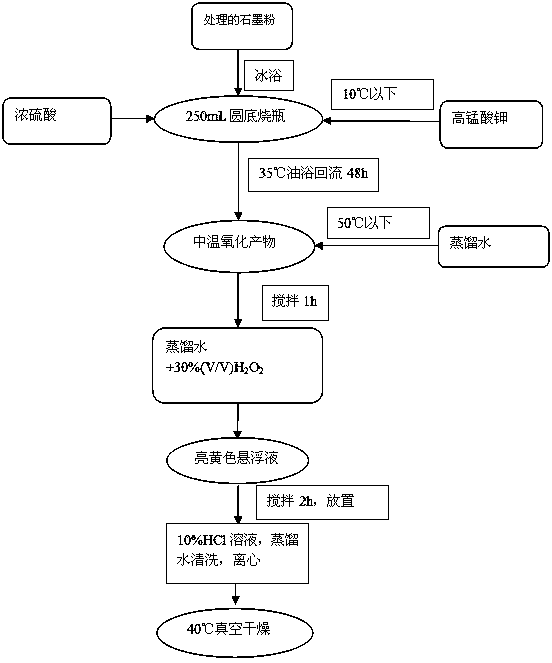

[0070] Specific embodiment three: in the present embodiment, the improved Hummer's method is selected to prepare graphite oxide. Graphite adopts natural flake graphite, using P 2 o 5 , KMnO 4 、K 2 S 2 o 8 , concentrated H 2 SO 4 Several mixtures such as graphite are pre-oxidized ( figure 1 ) to get expanded graphite. Then add a certain amount of sodium nitrate and concentrated sulfuric acid to the treated graphite, stir and mix evenly in an ice bath, slowly add a strong oxidizing agent such as potassium permanganate, keep the temperature not exceeding 4°C, ice bath for 1-4h, and then directly Graphite is oxidized through a moderate temperature (35°C) process. Add a large amount of water to dilute, then add hydrogen peroxide to reduce the remaining oxidant. The product was washed with hydrochloric acid and distilled water, and dried in vacuum to obtain graphite oxide ( figure 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com