Method for preparing high-temperature-resistant super-hydrophobic coating in situ

A super-hydrophobic coating, in-situ preparation technology, applied in the field of in-situ preparation of super-hydrophobic coatings, can solve problems such as unfavorable environmental protection and human health, high requirements for the environment and operators, and poor coating surface adhesion. , to achieve the effect of easy control, wide application value and high degree of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

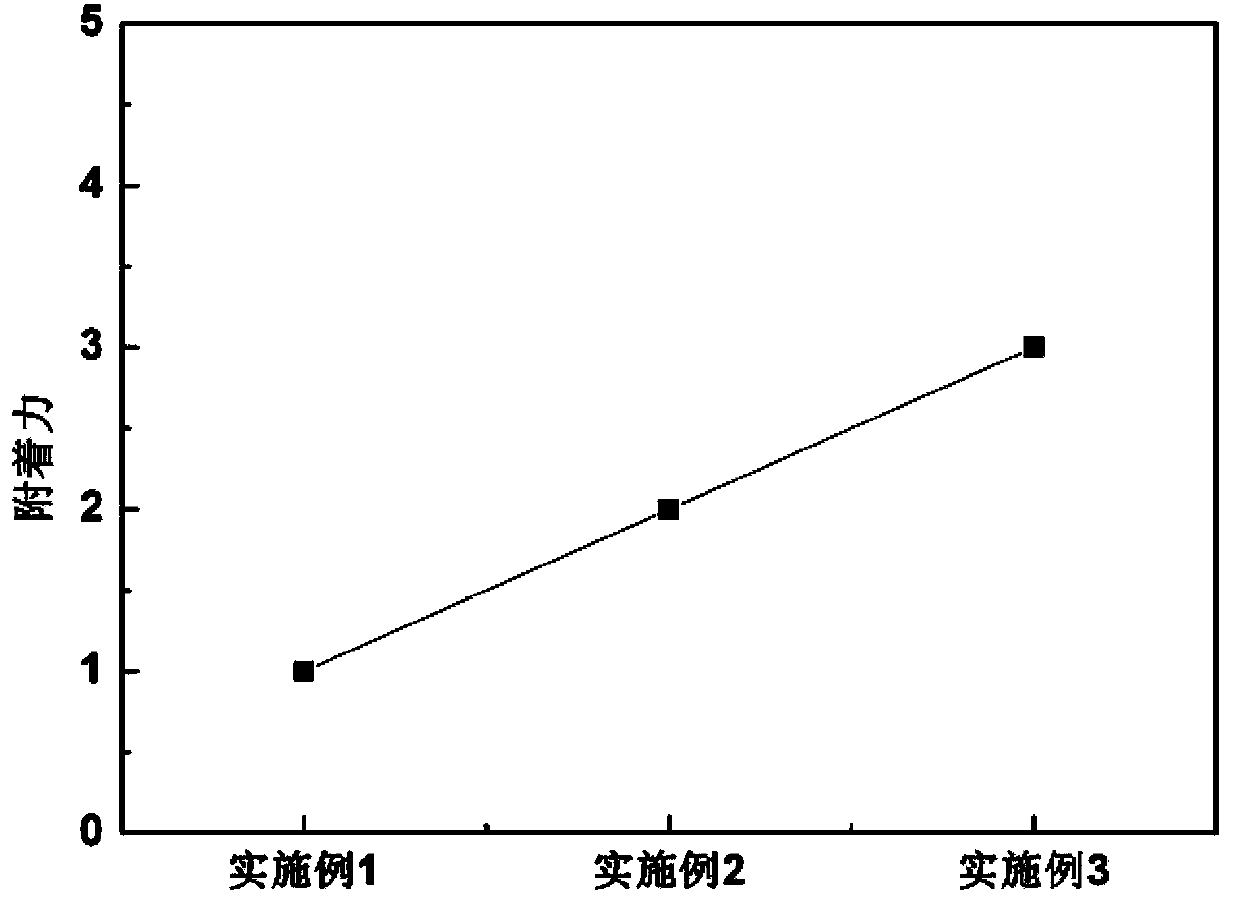

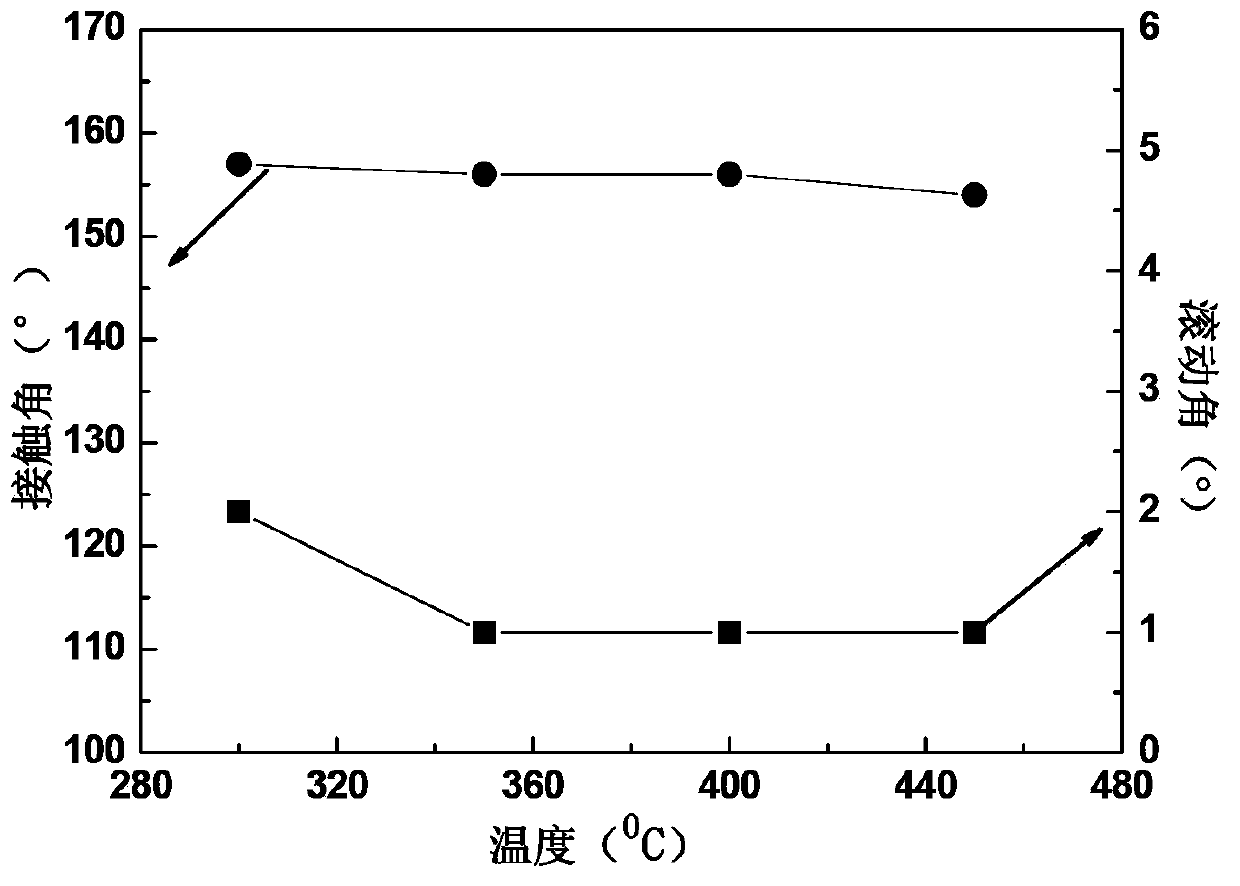

Embodiment 1

[0029] The in-situ preparation method of the high temperature resistant superhydrophobic coating of the present embodiment comprises the following steps:

[0030] (1) In-situ copolymerization of organosilicon monomers and inorganic particles: Add 0.5g of silica nanoparticles to 15ml of ethanol solution containing 2ml of water and raise the temperature to 80°C, add 1.50g of Add alkane monomer and drop a few drops of hydrochloric acid as a catalyst to stir for 3 hours, then add 0.82g propyltrimethoxysiloxane monomer to the above system and react for 3 hours, and finally add 2.68g methyltrimethoxysiloxane monomer Reaction 10h, obtained organic-inorganic hybrid system;

[0031] (2) Preparation of sol nanoparticles: Add 4ml tetraethyl orthosilicate dropwise to 5ml ethanol solution containing 2ml ammonia water at 60°C, and keep warm for 3 hours to prepare sol nanoparticles that can exist stably;

[0032] (3) Preparation of coating solution: Add the sol nanoparticles prepared in ste...

Embodiment 2

[0037] The in-situ preparation method of the high temperature resistant superhydrophobic coating of the present embodiment comprises the following steps:

[0038] (1) In-situ copolymerization of organosilicon monomers and inorganic particles: Add 0.6g of silica nanoparticles to 20ml of ethanol solution containing 3ml of water and raise the temperature to 70°C, add 1.70g of diphenyldimethoxy Add siloxane monomer and drop a few drops of hydrochloric acid as a catalyst to stir for 4 hours, then add 1.00g of propyltrimethoxysiloxane monomer to the above system and stir for 4 hours, and finally add 3.00g of methyltrimethoxysiloxane The alkane monomer was stirred and reacted for 12 hours to obtain an organic-inorganic hybrid system.

[0039] (2) Preparation of sol nanoparticles: Add 3ml tetraethyl orthosilicate dropwise to 50ml ethanol solution containing 3ml ammonia water at 50°C, heat and stir for 5 hours to prepare sol nanoparticles that can exist stably;

[0040] (3) Preparatio...

Embodiment 3

[0045] The in-situ preparation method of the high temperature resistant superhydrophobic coating of the present embodiment comprises the following steps:

[0046] (1) In-situ copolymerization of organosilicon monomers and inorganic particles: Add 1.0g of silica nanoparticles to 30ml of ethanol solution containing 4ml of water, raise the temperature to 75°C, and dissolve 3.1g of diphenyldimethoxysilane Add oxane monomer and drop a few drops of hydrochloric acid as a catalyst to stir for 5 hours, then add 1.5g of propyltrimethoxysiloxane monomer to the above system for 3 hours, and finally add 5.4g of methyltrimethoxysiloxane monomer The solid was stirred and reacted for 12 hours to obtain an organic-inorganic system.

[0047] (2) Preparation of sol nanoparticles: Add 2ml tetraethyl orthosilicate dropwise to 50ml ethanol solution containing 4ml ammonia water at 70°C, heat and stir for 4 hours to prepare sol nanoparticles that can exist stably;

[0048] (3) Preparation of coatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com