Modified walnut-shell adsorbent containing double amidoxime groups and preparation method thereof

A bisamidoxime and adsorbent technology, which is applied in the field of modified walnut shell adsorbent and its preparation, can solve the problems of insufficient source of raw materials, low mechanical strength and adsorption capacity, complicated process, etc., and achieve excellent adsorption capacity, treatment Remarkable effect and wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

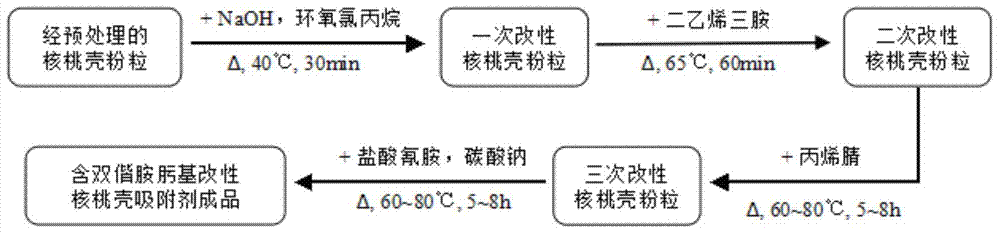

[0031] combine figure 1 , the concrete process of a kind of preparation method that contains bisamidoxime modified walnut shell adsorbent that the present invention proposes is as follows:

[0032] Step 1: Add sodium hydroxide solution and epichlorohydrin with a concentration of 1.25mol / L to the pretreated walnut shell powder with a particle size of 0.065-0.2mm, and the amount added is 1 gram of walnut shell powder 15mL of sodium hydroxide solution and 10mL of epichlorohydrin; placed in a constant temperature combined reactor at 40°C and stirred for 45min, the obtained product was washed with deionized water until neutral, and vacuum-dried at 65°C for 3 hours to obtain Primary modified walnut shell powder;

[0033] Step 2, deionized water, sodium hydroxide powder and diethylenetriamine are added in the primary modified walnut shell powder that step 1 makes, and the addition is that every gram of primary modified walnut shell powder adds 25mL deionized water, 0.25g of sodium ...

Embodiment 2

[0037] combine figure 1 , the concrete process of a kind of preparation method that contains bisamidoxime modified walnut shell adsorbent that the present invention proposes is as follows:

[0038] Step 1: Add 1mol / L sodium hydroxide solution and epichlorohydrin to the pretreated walnut shell powder with a particle size of 0.065-0.2 mm, and the amount added is 7.5 per gram of walnut shell powder. mL of sodium hydroxide solution and 10 mL of epichlorohydrin; placed in a constant temperature combined reactor and stirred at 40°C for 30 minutes, the obtained product was washed with deionized water until neutral, and dried in vacuum at 65°C for 3 hours to obtain Primary modified walnut shell powder;

[0039] Step 2, deionized water, sodium hydroxide powder and diethylenetriamine are added in the primary modified walnut shell powder that step 1 makes, and the addition is that every gram of primary modified walnut shell powder adds 50mL deionized water, 0.25g of sodium hydroxide po...

Embodiment 3

[0043] combine figure 1 , the concrete process of a kind of preparation method that contains bisamidoxime modified walnut shell adsorbent that the present invention proposes is as follows:

[0044] Step 1: Add 1mol / L sodium hydroxide solution and epichlorohydrin to the pretreated walnut shell powder with a particle size of 0.065 to 0.2mm, and the addition amount is 22.5 per gram of walnut shell powder. mL of sodium hydroxide solution and 2 mL of epichlorohydrin; they were placed in a constant temperature combined reactor and stirred at 40°C for 30 minutes, the obtained product was washed with deionized water until neutral, and dried in vacuum at 65°C for 5 hours to obtain Primary modified walnut shell powder;

[0045] Step 2, deionized water, sodium hydroxide powder and diethylenetriamine are added in the primary modified walnut shell powder that step 1 makes, and the addition is that every gram of primary modified walnut shell powder adds 25mL deionized water, 0.25g of sodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com